Epoxy group cross-linked microsphere, and preparation method and application thereof

A cross-linked microsphere and epoxy-based technology, applied in the direction of additive processing, can solve the problems of high viscosity of cross-linking agent, viscosity limitation of light-curing resin, excessive use of 3D light-curing technology, etc., to improve mechanical properties, size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

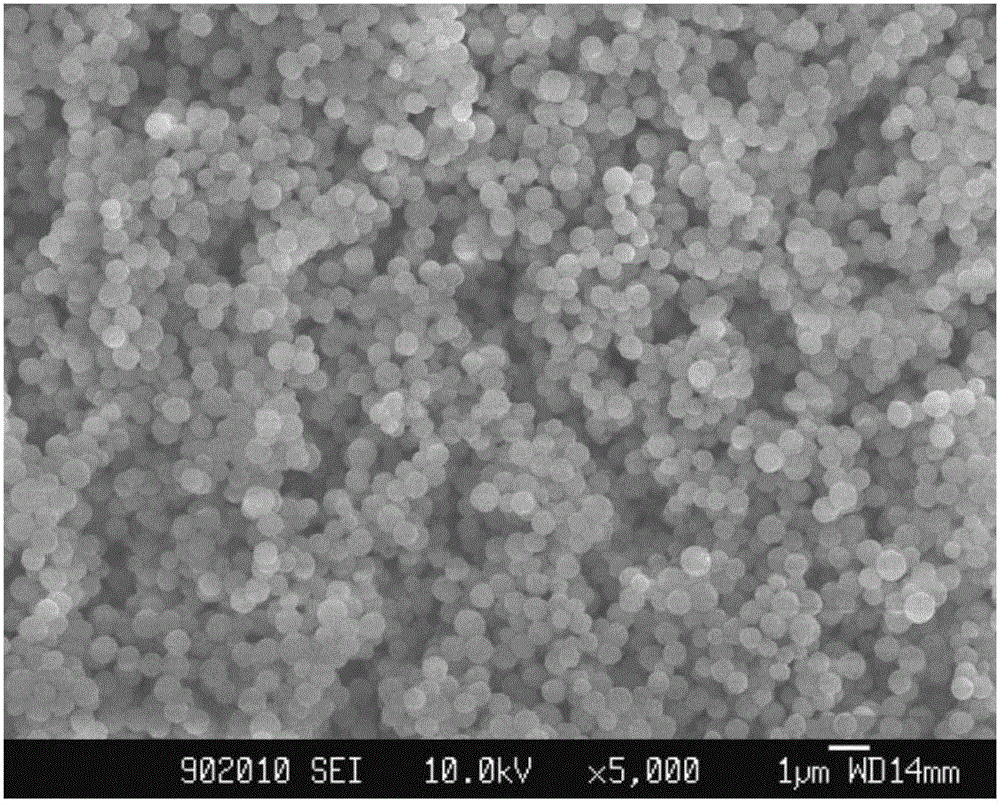

Embodiment 1

[0032] An epoxy-based cross-linked microsphere, made of the following components by weight: 150 parts by weight of polyglycidyl methacrylate (GMA), 2 parts by weight of 2,4,6-trimethylbenzoyl- Diphenylphosphine oxide, 8 parts by weight of 1-hydroxy-cyclohexyl phenone, 18 parts by weight of PVP, 812 parts by weight of ethanol / water mixed solution with a mass ratio of 1:1, 10 parts by weight of 1,6-hexanediol bis Acrylate.

[0033] The preparation method of above-mentioned epoxy-based cross-linked microspheres comprises the following steps:

[0034] Step 1: 150 parts by weight of polyglycidyl methacrylate (GMA), 2 parts by weight of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 8 parts by weight of 1-hydroxyl-cyclohexylbenzene Ketone and 18 parts by weight of PVP are placed in the reactor, and 812 parts by weight of ethanol / water mixed solution are added to stir evenly, and nitrogen gas is passed for 15 minutes;

[0035] Step 2: The reactor is sealed with a cover made of qua...

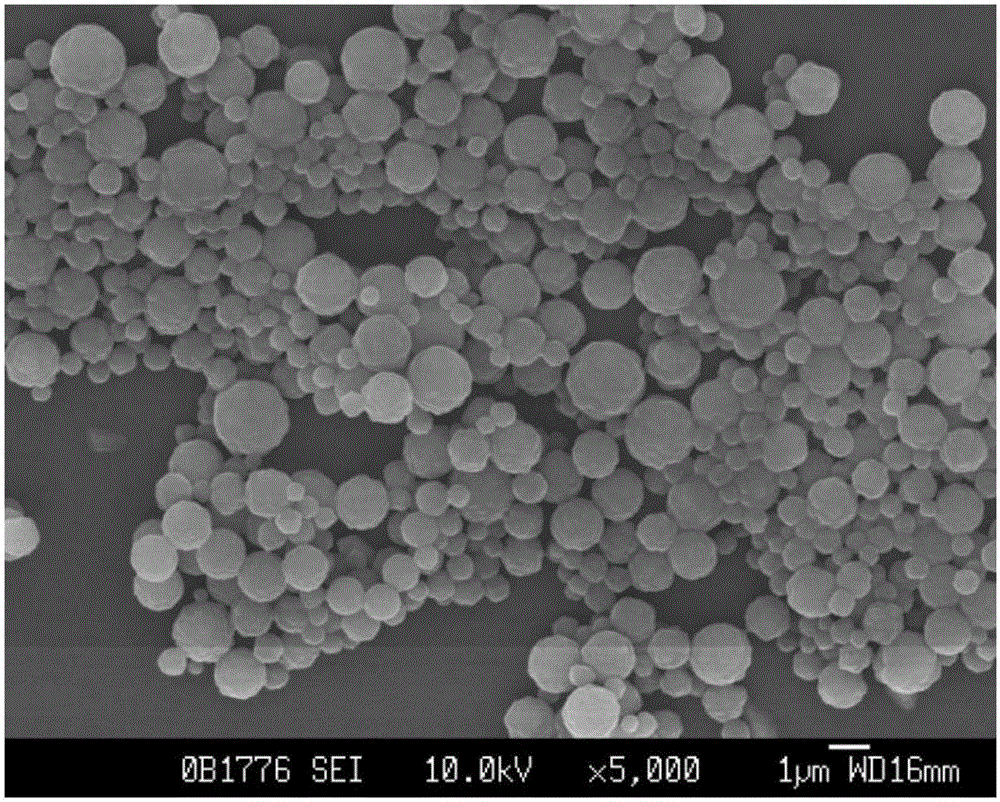

Embodiment 2

[0040] An epoxy-based crosslinked microsphere, made of the following components by weight: 50 parts by weight polyglycidyl methacrylate (GMA), 0.25 parts by weight α, α-dimethoxy-α-phenyl Acetophenone, 5 parts by weight of PVP, 945 parts by weight of ethanol / water mixed solution with a mass ratio of 0.8:1, and 1 part by weight of tripropylene glycol diacrylate.

[0041] The preparation method of above-mentioned epoxy-based cross-linked microspheres comprises the following steps:

[0042] Step 1: 50 parts by weight of polyglycidyl methacrylate (GMA), 0.25 parts by weight of α, α-dimethoxy-α-phenylacetophenone, and 5 parts of PVP are placed in the reactor, and 950 Stir the ethanol / water mixed solution with a mass ratio of 0.8:1 in parts by weight evenly, and pass nitrogen gas for 15 minutes;

[0043] Step 2: The reactor is sealed with a cover made of quartz glass, and a high-pressure mercury lamp (light intensity 9mW / cm 2 ) illuminate the reaction mixture from the top of the r...

Embodiment 3

[0048] An epoxy-based cross-linked microsphere, made of the following components by weight: 200 parts by weight polyglycidyl methacrylate (GMA), 2 parts by weight 2-phenyl-2-dimethylamino-1- (4-morpholine phenyl)-butanone, 13 parts by weight 2-methyl-1-[4-methylmercaptophenyl]-2-morpholine acetone, 30 parts by weight PVP, 745 parts by weight mass ratio is 0.5: 1 ethanol / water mixed solution, 10 parts by weight of dipropylene glycol diacrylate, and 5 parts by weight of 1,6-hexanediol diacrylate.

[0049] The preparation method of above-mentioned epoxy-based cross-linked microspheres comprises the following steps:

[0050] Step 1: 200 parts by weight of polyglycidyl methacrylate (GMA), 2 parts by weight of 2-phenyl-2-dimethylamino-1-(4-morpholine phenyl)-butanone, 13 parts by weight of 2 -Methyl-1-[4-methylmercaptophenyl]-2-morpholine acetone, 30 parts by weight of PVP are placed in the reactor, add 745 parts by weight of ethanol / water mixed solution with a mass ratio of 0.5:1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com