Sow feeding method

A feeding method and technology for breeding sows, which are applied in the field of breeding sows, can solve the problems that sows do not exert their best potential and do not receive good economic benefits, so as to shorten the estrus days, improve the utilization efficiency, and achieve lactation. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

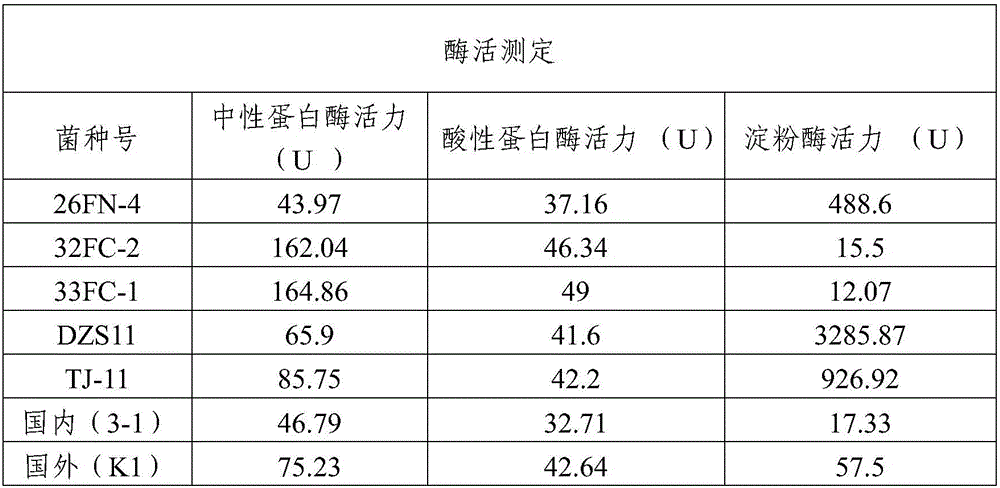

[0029] The screening of embodiment 1 Bacillus subtilis DZS11

[0030] 1. Primary screening

[0031] Collect 10 piglet feces samples, weigh 10g soil samples respectively, add 90mL sterile water to make bacterial suspension, treat in 80°C water bath for 20min, vibrate at 180r / min for 30min, gradually dilute to a suitable gradient, and spread on LB On the culture medium, 86 suspected bacillus strains were obtained.

[0032] Milk culture medium (for primary screening of protease): 5g skimmed milk dissolved in 50ml distilled water; 1.5g agar dissolved in 50ml distilled water, the two liquids were sterilized separately, when cooled to 45-50°C, mix the two liquids and pour the plates , Serve with a milk tablet. Invert the plate overnight to dry the surface moisture, then spot the bacteria on the plate, mix and invert the plate, and set aside overnight. When preparing this medium, do not mix milk and agar to sterilize to prevent the milk from coagulating.

[0033] Starch hydrolysi...

Embodiment 2

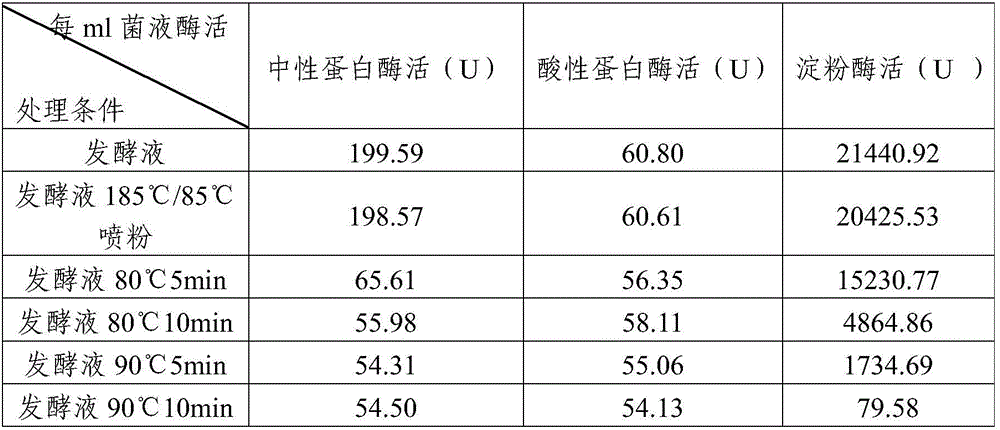

[0055] Embodiment 2 Bacillus subtilis DZS11 bacterium fluid heat-resistant performance measurement

[0056] After the Bacillus subtilis was fermented in a 30L fermenter for 18 hours, the fermentation liquid was treated for several times, and its amylase, neutral protease and acid protease were measured respectively. The measurement results are shown in Table 2:

[0057] Table 2 Heat resistance results of enzyme activity of Bacillus subtilis DZS11

[0058]

[0059] From the experimental results, it can be found that after the fermentation broth is sprayed dry under the conditions of the inlet air temperature of 185°C and the outlet air temperature of 80°C, the three enzyme activities are basically unchanged compared with the original fermentation broth, which shows that the spray drying process has little effect on the enzyme activity. There will be no loss. Its acidic protease, no matter it is treated under various conditions, does not decrease much compared with the orig...

Embodiment 3

[0060] The fermentation of embodiment 3 bacillus subtilis DZS11 and the preparation of bacteria powder

[0061]Fermentation of Bacillus subtilis DZS11: The fermentation medium used is prepared as follows: 0.5% corn flour, 1% bean cake powder, 0.4% sucrose, 0.6% fish meal, 0.1% calcium carbonate, 0.1% potassium dihydrogen phosphate, 0.2% magnesium sulfate, sulfuric acid Ferrous 0.025%, manganese sulfate 0.025%. Prepare the fermented liquid in proportion, then adjust the pH to 7.2. After sterilizing at 121°C for 30 minutes, cool down to 37°C, inoculate seed solution with a bacterial age of 16 hours, inoculum amount of 3%, 37°C, keep the rotation speed at 300rpm, air ratio 1:0.4, tank pressure 0.05. Cultivate to 18h as the end point of fermentation, put the tank, and the number of viable bacteria of Bacillus subtilis DZS11 is 6.21×10 9 CFU / mL.

[0062] Spray-dried protective agent (0.8% of glycerol, 0.2% of sodium glutamate, 19% of cornstarch) was added to the fermented liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com