Edible corn protein-based food packaging material and preparation method for same

A technology of food packaging and zein, applied in the field of food packaging materials, can solve problems such as far from reaching industrialized production, complex processes, and harsh synthesis and preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention at first provides a kind of preparation method of edible zein-based food packaging material, and this method comprises:

[0030] Step 1: Mix biomacromolecules / macromolecular materials with entanglement points with a solvent to obtain a mixed solution;

[0031] Step 2: Inject the mixed solution obtained in Step 1 into the reaction pusher, maintain a fixed push flow rate of 0.5-50mL / h, and the electrospinning voltage is 5-50kV. The positive electrode of the voltage is connected to the outlet metal of the reaction pusher, and the negative electrode is connected to On the yarn taker connected to the earth, the distance from the outlet metal of the reaction pusher to the yarn taker is 5-50cm, and the electrospinning time is 0.5-24h, and the zein-based food packaging material is prepared.

[0032] According to the present invention, the biomacromolecule / and the macromolecular material with entanglement points are mixed with solvent and water, preferably ...

Embodiment 1

[0038] Weigh 1g of polyethylene oxide, add 99g, that is, 115.5mL of solvent ethanol and water, the final solution concentration is 1wt%, and magnetically stir it for 24 hours to make it completely mixed and ready for use. Inject the uniformly mixed solution into the reaction pusher, maintain a fixed push flow rate of 2mL / h, and the electrospinning voltage is 20kV. The positive pole of the voltage is connected to the outlet metal of the reaction pusher, and the negative pole is connected to the wire take-up connected to the ground. To ensure the safety of personnel and equipment, the distance from the outlet metal of the reaction pusher to the take-up device is 8cm, and the electrospinning time is 1h, and the zein-based food packaging material is prepared.

Embodiment 2

[0040] Weigh 10g of polyethylene oxide, add 87g, that is, 105mL of solvent ethanol and water, the final solution concentration is 10wt%, and magnetically stir it for 24 hours to make it completely mixed and ready for use. Inject the uniformly mixed solution into the reaction pusher, maintain a fixed push flow rate of 2mL / h, and the electrospinning voltage is 20kV. The positive pole of the voltage is connected to the outlet metal of the reaction pusher, and the negative pole is connected to the wire take-up connected to the ground. To ensure the safety of personnel and equipment, the distance from the outlet metal of the reaction pusher to the take-up device is 8cm, and the electrospinning time is 1h, and the zein-based food packaging material is prepared.

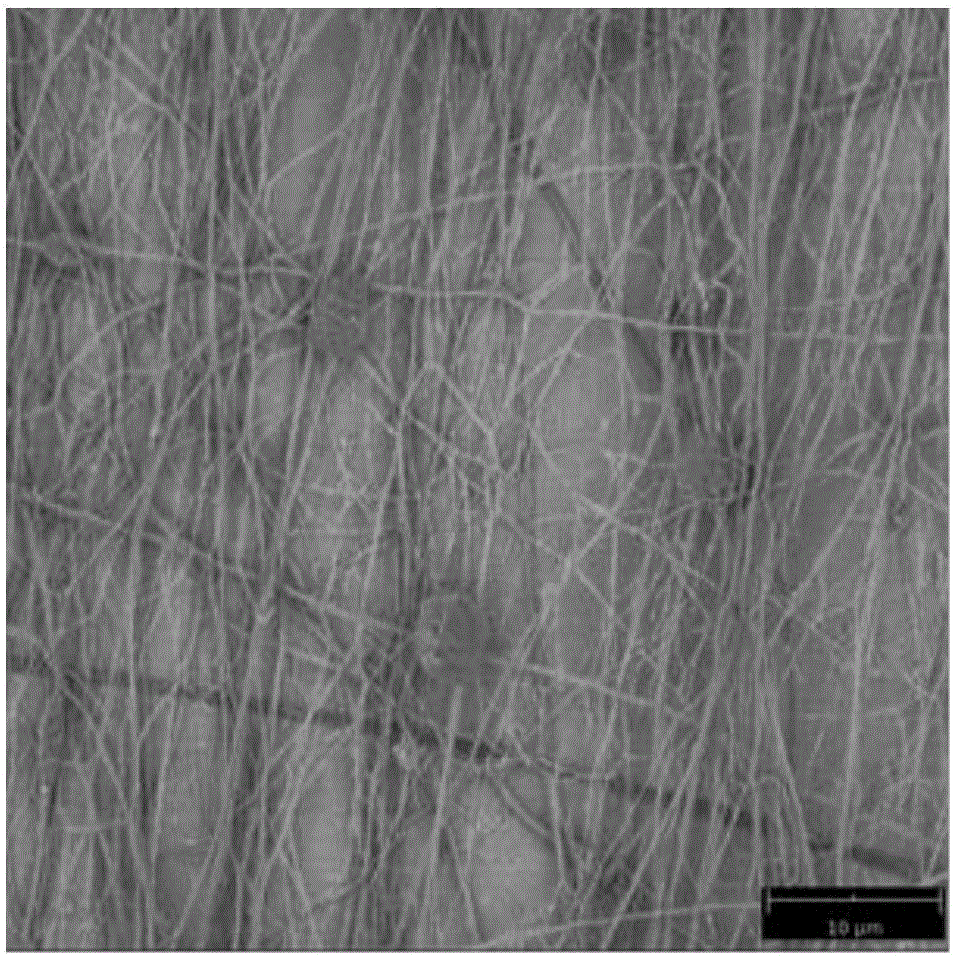

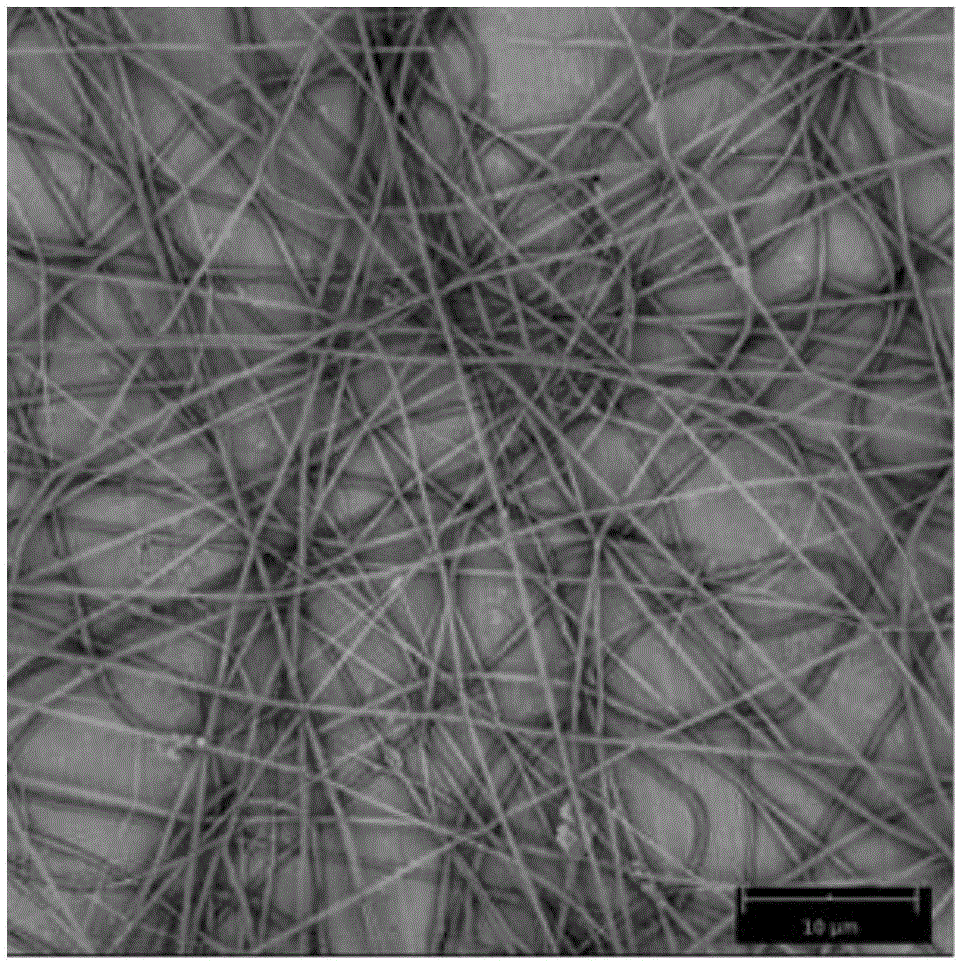

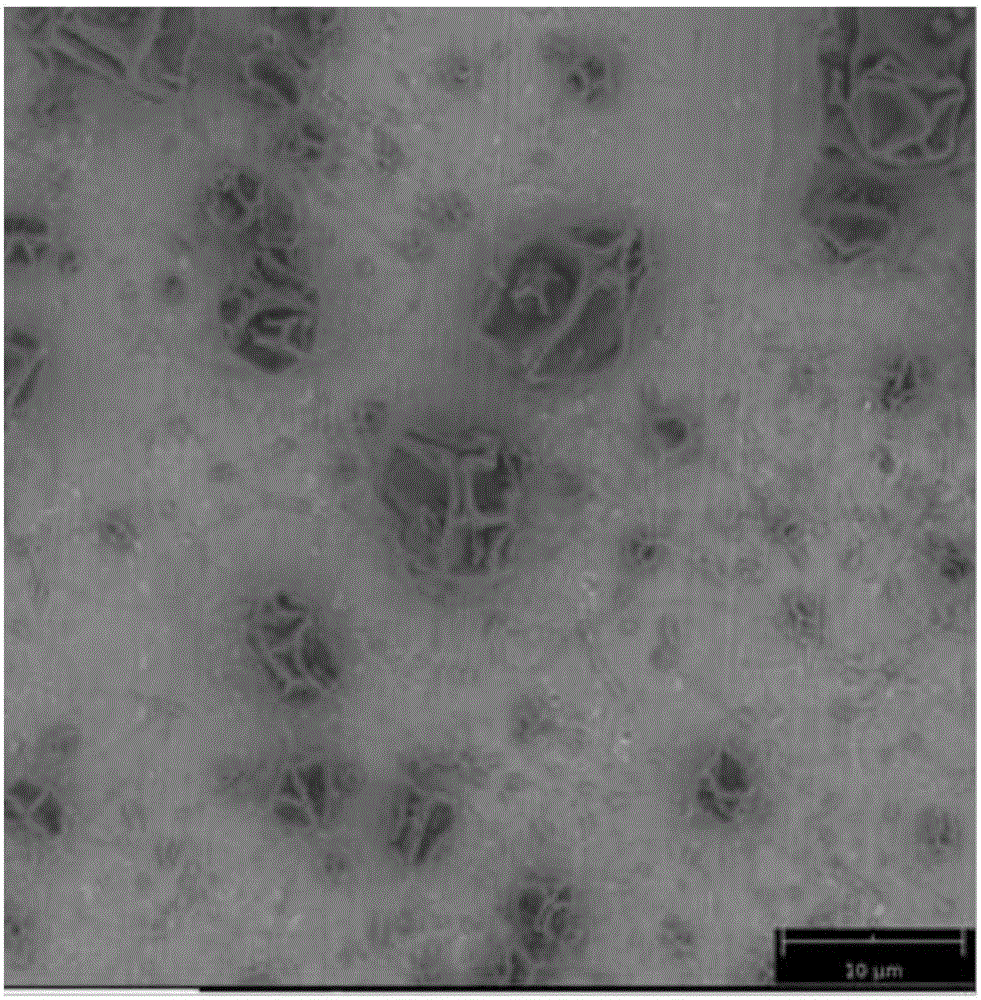

[0041] figure 1 Scanning electron microscope picture of the edible zein-based food packaging material prepared in Example 2 of the present invention; figure 1 It shows that the preparation of defect-free gliadin-based pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com