Lignin-modified whole bio-based PBSA biodegradable plastic and preparation method thereof

A technology of biodegradable plastics and biodegradable resins, applied in flat products, other household appliances, household appliances, etc., can solve the problems of high carbon dioxide, consumption of petroleum resources, etc., and achieve the effects of low production cost, cost reduction and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Preparation of lignin-modified PBSA biodegradable plastics

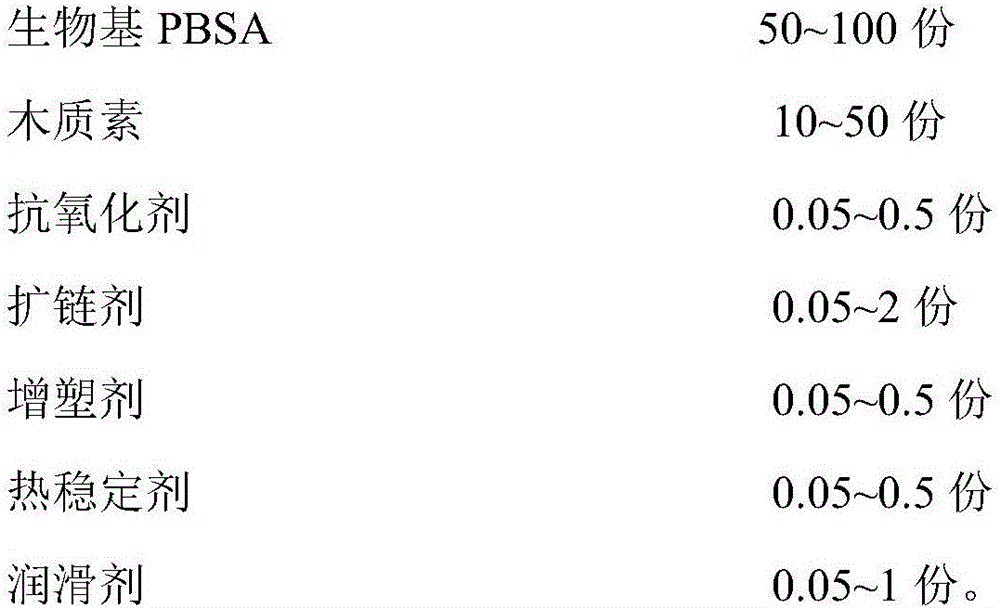

[0037] (1) In terms of parts by weight, the proportioning ratio of each raw material used is as follows:

[0038]

[0039]

[0040] (2) Concrete preparation method, comprising the following steps:

[0041] (1) Synthesize the full bio-based PBSA biodegradable resin raw material according to the above method;

[0042] (2) Dry a certain amount of bio-based PBSA and lignin powder (150 mesh) at 25°C and 0-5000Pa for 2.0h;

[0043] (3) Add dry bio-based PBSA, lignin powder and bisphenol A, dibutyl hydroxytoluene, triethyl citrate, epoxidized soybean oil, zinc stearate in the high mixer, and control the material temperature to 100-105°C, mix for 15 minutes, the speed is 900r / min;

[0044] (4) extruding and granulating the obtained mixed material through a twin-screw extruder, controlling the extrusion temperature to be 120-130° C. to obtain lignin-bio-based PBSA composite plastic particles;

[...

Embodiment 2

[0046] Example 2 Preparation of lignin-modified bio-based PBSA biodegradable plastics

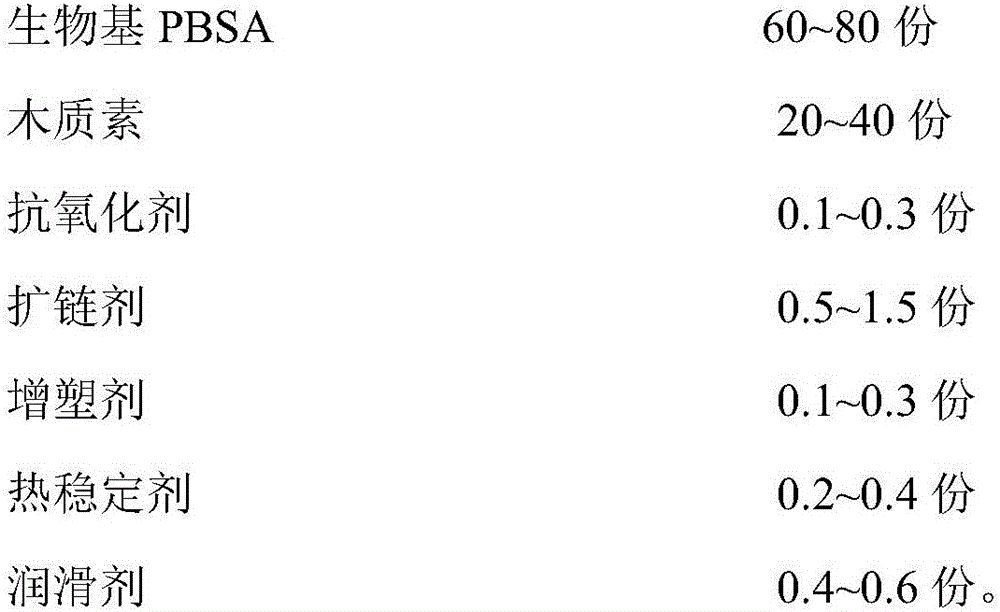

[0047] (1) In terms of parts by weight, the proportioning ratio of each raw material used is as follows:

[0048]

[0049] (2) Concrete preparation method, comprising the following steps:

[0050] (1) Synthesize the full bio-based PBSA biodegradable resin raw material according to the above method;

[0051] (2) Dry a certain amount of bio-based PBSA and lignin (200 mesh) at 25°C and 0-5000Pa for 3 hours;

[0052] (3) Add dry bio-based PBSA, lignin and acetyl tri-n-butyl citrate, resorcinol dihydroxyethyl ether, butyl hydroquinone, epoxidized soybean oil, stearin into the high mixer Calcium acid, control the material temperature to 110°C, mix for 20 minutes, and the rotating speed is 1000r / min;

[0053] (4) extruding and granulating the obtained mixed material through a twin-screw extruder, controlling the extrusion temperature to be 130-140° C. to obtain lignin-PBSA composite plastic ...

Embodiment 3

[0055] Example 3 Preparation of lignin-modified bio-based PBSA biodegradable plastics

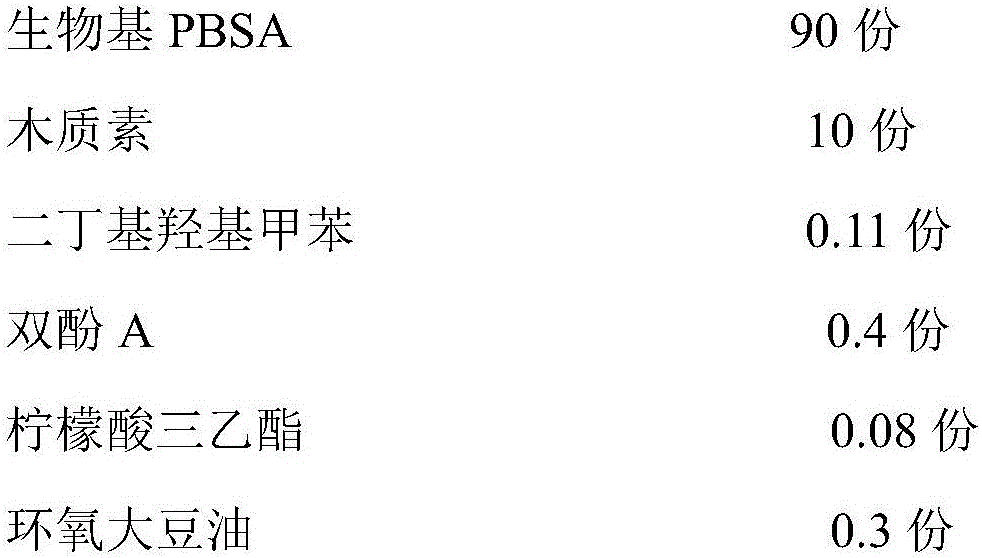

[0056] (1) In terms of parts by weight, the proportioning ratio of each raw material used is as follows:

[0057]

[0058] (2) Concrete preparation method, comprising the following steps:

[0059] (1) Synthesize the full bio-based PBSA biodegradable resin raw material according to the above method;

[0060] (2) Dry a certain amount of bio-based PBSA and lignin (250 mesh) at 25°C and 0-5000Pa for 3 hours;

[0061] (3) Add dried bio-based PBSA, lignin, maleic anhydride, glycerol triacetate, butyl hydrodiphenol, 1,4-butanediol, zinc stearate to the high mixer to control The material temperature is 105°C, mixed for 25 minutes, and the rotation speed is 1000r / min;

[0062] (4) extruding and granulating the obtained mixed material through a twin-screw extruder, controlling the extrusion temperature to be 155-160° C. to obtain lignin-PBSA composite plastic granules;

[0063] (5) The lignin-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com