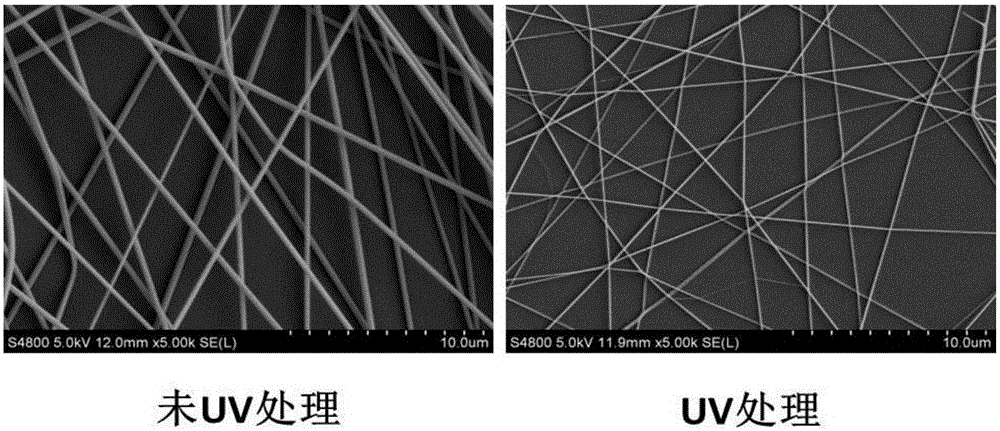

Method for preparing indium oxide/aluminium oxide nanofiber filed effect transistor through UV light pretreatment

A field-effect transistor and aluminum oxide nanotechnology, which is applied in the direction of nanotechnology, nanotechnology, fiber chemical characteristics, etc., can solve the problems of large-area application limitations, complex operation procedures, etc., and achieve broad application prospects, simple process, and improved operation stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

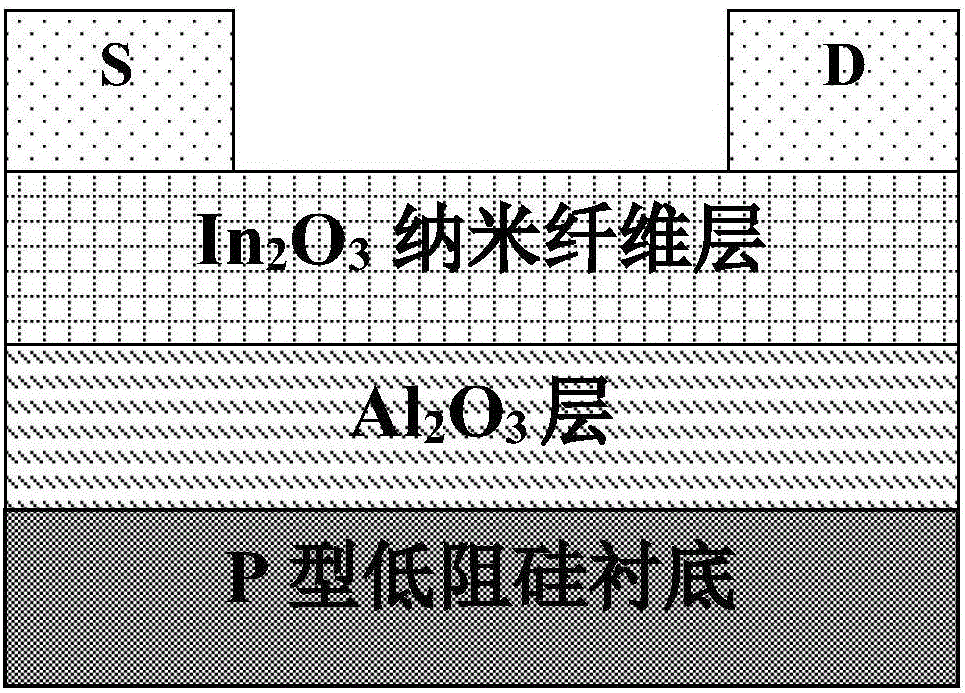

[0034] The process steps of preparing indium oxide / alumina nanofiber field-effect transistors by UV light pretreatment involved in this embodiment mainly include:

[0035] (1) Preparation of Al 2 o 3 High-k dielectric film:

[0036] First add aluminum nitrate to N,N dimethylformamide to prepare Al with a concentration of 0.3 mol / L 2 o 3 The dielectric layer precursor solution was rotated in a magnetic stirrer for 6 hours to obtain a pure and transparent dielectric layer precursor solution, which was left to stand for 24 hours for later use; single-sided polished P-type low-resistance silicon (~0.0015Ω cm) was used as Substrate, use hydrofluoric acid, acetone and alcohol to ultrasonically clean the low-resistance silicon substrate for 10 minutes each, then rinse with deionized water and dry it with high-purity nitrogen for later use; spin-coated Al 2 o 3 For the dielectric layer precursor solution, first set the homogenizer at 500 rpm for 5 seconds, then set it at 5000 rp...

Embodiment 2

[0050] The UV light pretreatment involved in this embodiment prepares In 2 o 3 / Al 2 o 3 The process steps of nanofiber field effect transistor mainly include:

[0051] (1) Preparation of high-k alumina dielectric layer by solution method; silicon dioxide is a dielectric material that has been used on a large scale, and the process is mature, but the dielectric constant is only 3.9, and the capacitance per unit area is small, which makes the operating voltage of the device relatively low. Large, which is not conducive to energy saving and application in mobile terminals; the high-k alumina dielectric layer has a large dielectric constant, which greatly reduces the operating voltage, and can have a greater physical thickness under the same capacitance per unit area.

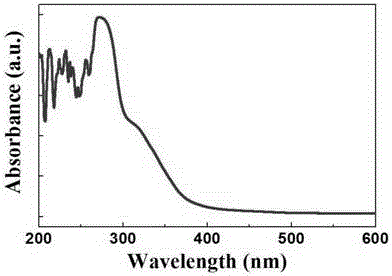

[0052] (2) On the prepared dielectric layer, use electrospinning technology to deposit In 2 o 3 Nanofibers are used as the channel layer; nanofibers have unique current transport characteristics, and have hug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com