Liquid-phase ZnO coated Ni<2+>-Cr<3+> doped amorphous cobalt nitrate lithium battery anode material and preparation method thereof

A technology of lithium cobalt nitrate and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of being easily corroded by electrolyte, high diffusion activation energy, affecting the reversibility of materials, etc., to improve the electronic conductivity, The effect of expanding diffusion and migration channels and facilitating rapid conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

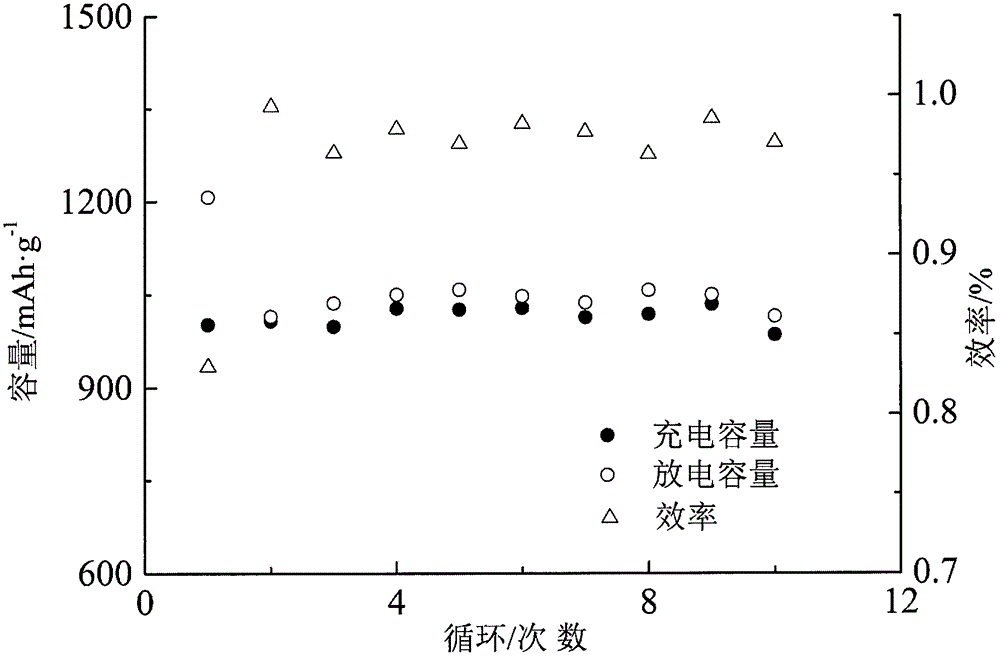

Embodiment 1

[0013] Example 1: Dissolving cobalt nitrate hexahydrate, chromium nitrate nonahydrate with a substance amount of 0.5% cobalt nitrate hexahydrate, and nickel nitrate hexahydrate with a substance amount of 0.5% cobalt nitrate hexahydrate in absolute ethanol to form a total metal ion concentration 0.5mol·L -1 ethanol solution, the solution was added to 16 drops min. -1 The speed is added dropwise to the toluene of the same quality as the ethanol solution, and the stirring paddle is used to stir at a speed of 1300 rpm while the dropwise addition is completed. After the dropwise addition is completed, continue to stir for 6 minutes and leave standstill for 6 minutes. This mixture is called mixture 1. ; Dissolve zinc acetate dihydrate with 0.5% cobalt nitrate hexahydrate in absolute ethanol to form a concentration of 0.1 mol·L -1 ethanol solution, this solution was added to 22 drops min -1 Drop into mixture I at the speed of 400rpm, stir until the addition is completed and stand f...

Embodiment 2

[0014] Example 2: Dissolving cobalt nitrate hexahydrate, chromium nitrate nonahydrate with a substance amount of 1% cobalt nitrate hexahydrate, and nickel nitrate hexahydrate with a substance amount of 1.5% cobalt nitrate hexahydrate in absolute ethanol to form a total metal ion concentration 1mol·L -1 ethanol solution, the solution was added to 20 drops min -1 The speed is added dropwise to the toluene of the same quality as this ethanol solution, and the stirring paddle is used to stir at a speed of 1350 rpm while the dropwise addition is completed. After the completion of the dropwise addition, stirring was continued for 7 minutes and left standstill for 10 minutes. This mixture is called mixture 1. ; Dissolve zinc acetate dihydrate with 1.5% cobalt nitrate hexahydrate in absolute ethanol to form a concentration of 0.2 mol·L -1 ethanol solution, this solution was added to 40 drops·min -1Drop into mixture I at the speed of 600rpm, stir until the addition is complete and st...

Embodiment 3

[0015] Example 3: Dissolving cobalt nitrate hexahydrate, chromium nitrate nonahydrate containing 5% cobalt nitrate hexahydrate, and nickel nitrate hexahydrate containing 5% cobalt nitrate hexahydrate in absolute ethanol to form a total metal ion concentration 1.5mol·L -1 ethanol solution, the solution was added to 30 drops min -1 The speed is added dropwise in the toluene of the same quality as this ethanol solution, and the stirring paddle is used to stir at a speed of 1500 rpm while dropping, and the stirring is continued for 15 minutes and left standstill for 15 minutes after the dropwise addition. This mixture is called mixture I. ; Dissolve zinc acetate dihydrate with 4.5% of cobalt nitrate hexahydrate in absolute ethanol to form a concentration of 0.3 mol·L -1 ethanol solution, this solution was added to 55 drops·min -1 Drop into mixture I at the speed of 750rpm, stir until the addition is complete and stand for 15 minutes at a speed of 750rpm; The system after this st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com