Preparation method of three-dimensional-structure graphene/carbon nanotube hybrid carbon material

A technology of carbon nanotubes and three-dimensional structures, applied in the direction of carbon nanotubes, graphene, nanocarbon, etc., can solve problems such as large contact resistance and limited application fields, and achieve reduced junction resistance, no environmental pollution, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

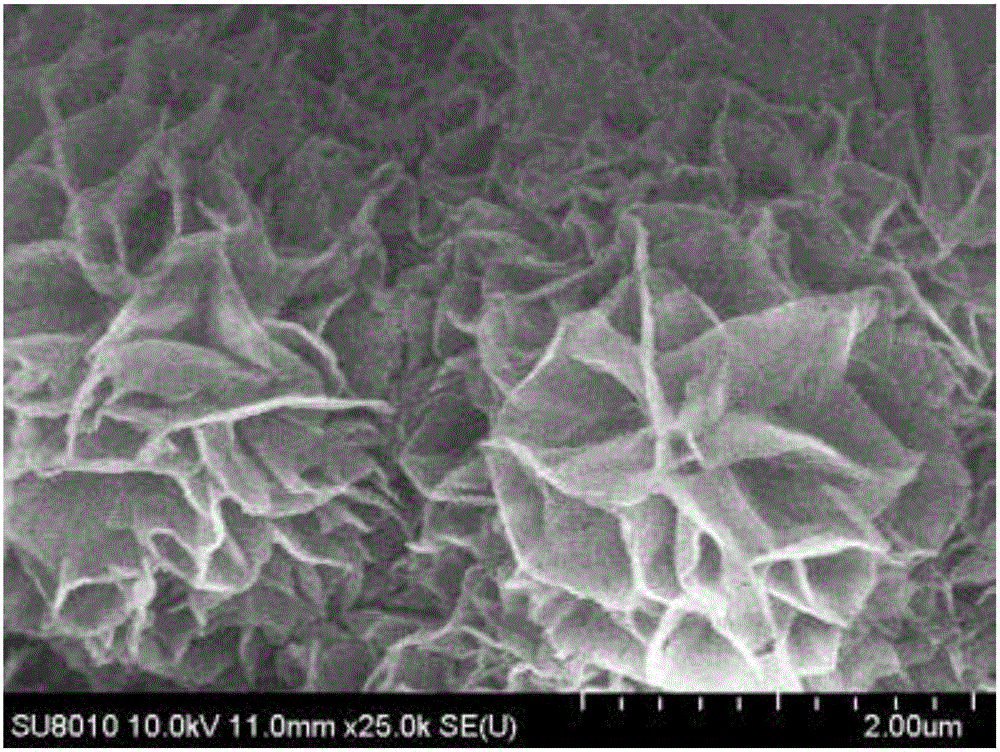

[0044] Dissolve 0.005mol of nickel chloride, 0.015mol of hexamethylenetetramine and 0.02mol of resorcinol in 30mL of water to obtain a mixed solution; Stand for reaction for 18 hours, and after cooling to room temperature, obtain the suspension; centrifuge and wash the above suspension, dry at room temperature for 24 hours, take the dried powder precursor and melamine according to the mass ratio of 1:5 and mix them into In a tube furnace, under the protection of nitrogen (nitrogen flow rate 50mL / min), the temperature was raised from room temperature to 700 °C at 2 °C / min, and kept at this temperature for 3 h; naturally cooled to room temperature, a black powder was obtained; the black Put the powder into a 100mL beaker, add 50mL of hydrochloric acid with a molar concentration of 8mol / L, and stir at 60°C for 48h; after that, filter with suction and wash with distilled water several times until the pH of the solution is 6.8-7.2, and the obtained precipitate is cooled at 80°C Aft...

Embodiment 2

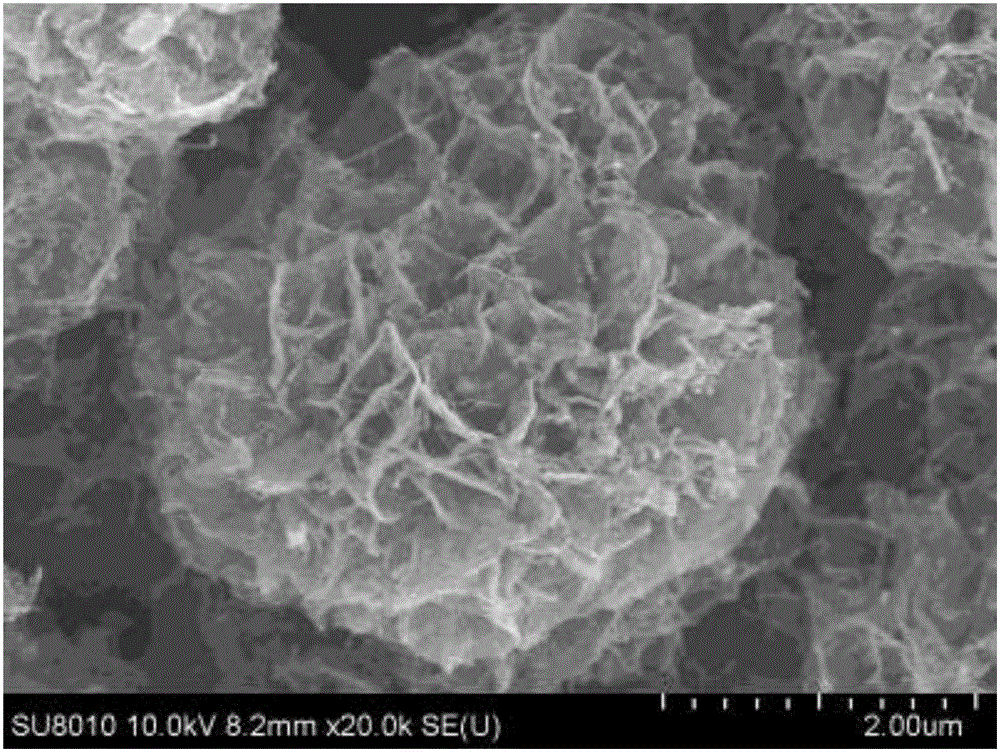

[0048] Dissolve 0.005mol nickel acetate, 0.015mol urea and 0.01mol glucose in 30mL distilled water to obtain a mixed solution; then transfer the mixed solution to a 50mL polytetrafluoroethylene reactor, conduct a hydrothermal reaction at 180°C for 12 hours, and cool to room temperature , to obtain a suspension; the suspension was centrifuged and washed at room temperature for 24 hours, and the dried powder precursor and melamine were mixed according to a mass ratio of 1:4, put into a tube furnace, and heated in an argon atmosphere. (Argon gas flow 50mL / min), the temperature was raised from room temperature to 800 °C at 2 °C / min, and kept at this temperature for 2 hours; after natural cooling to room temperature, a black powder was obtained; put the black powder into a 100 mL beaker, Add 50 mL of hydrochloric acid with a molar concentration of 6 mol / L, and stir at 50°C for 48 hours; after that, centrifuge and wash with distilled water several times until the pH of the solution i...

Embodiment 3

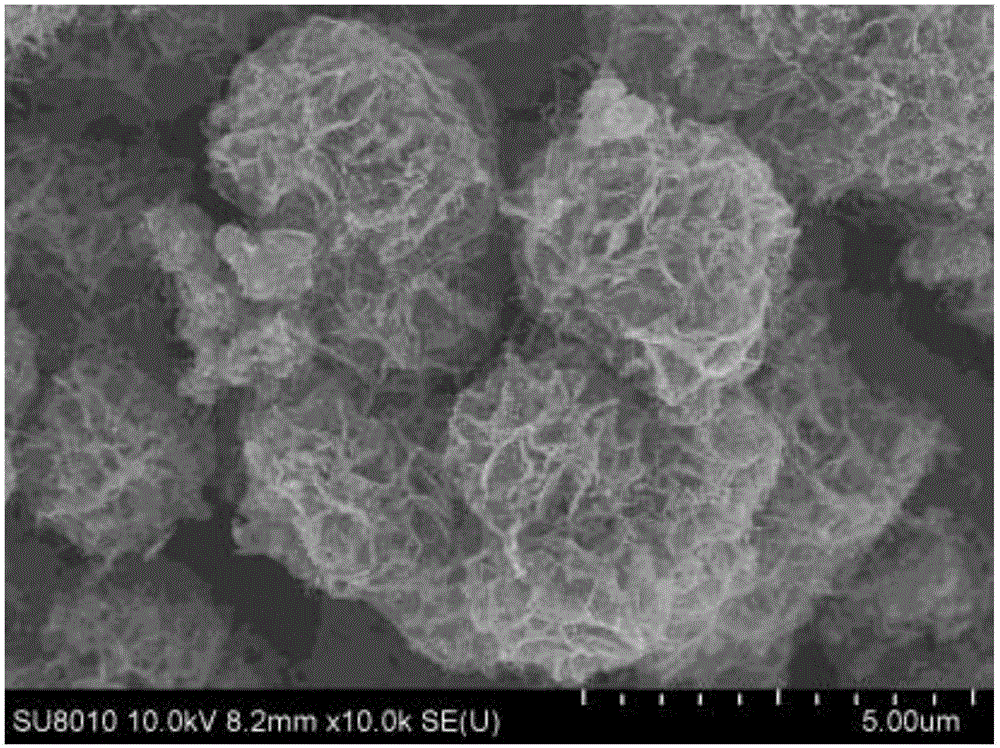

[0052] Dissolve 0.005 mol of nickel sulfate, 0.015 mol of potassium hydroxide and 0.015 mol of sucrose in 35 mL of distilled water to obtain a mixed solution; then transfer the mixed solution to a 50 mL polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 180°C for 24 hours; cool to After room temperature, the suspension was obtained; the suspension was centrifuged and washed at room temperature for 24 hours, and the dried powder precursor and dicyandiamide were mixed according to the mass ratio of 1:4, and put into a tube furnace. Under nitrogen atmosphere (nitrogen flow rate: 50mL / min), raise the temperature from room temperature to 900°C at 2°C / min, and keep it at this temperature for 1h; after naturally cooling to room temperature, a black powder is obtained; put the black powder into a 100mL beaker Add 50 mL of hydrochloric acid with a molar concentration of 6 mol / L, and stir at 80°C for 36 hours; after that, centrifuge and wash with distilled water seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com