Sulfur-doped three-dimensional porous cuprous oxide nano-material and application thereof to electrochemical hydrogen evolution reaction

A cuprous oxide, three-dimensional nano technology, applied in the direction of copper oxide/copper hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of difficult control of stability, reduced catalytic performance of catalysts, poor conductivity, etc. problem, achieve the effect of reducing intermediate energy, improving stability and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

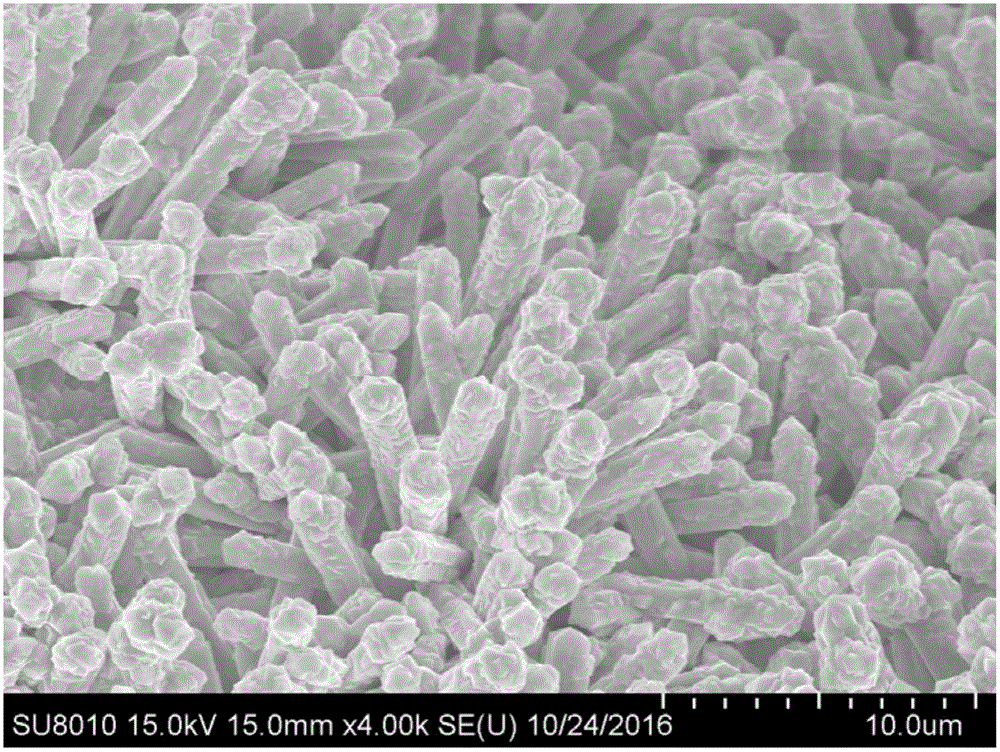

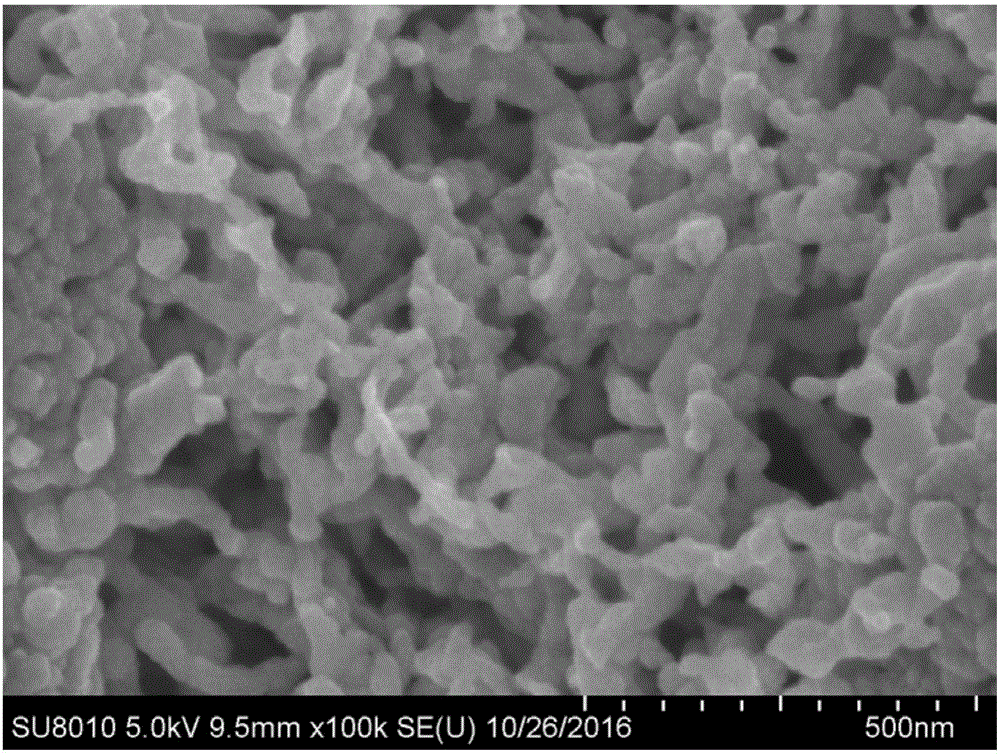

[0016] Example 1: This example prepares a three-dimensional nanoporous material of sulfur-doped cuprous oxide, which specifically includes the following steps:

[0017] (1) Dissolve 6.4g of sodium hydroxide and 1.368g of ammonium persulfate in 60ml of deionized water, and stir evenly to obtain a mixed solution.

[0018] (2) Put the foamed copper obtained after cleaning into the mixed solution, soak at room temperature 25°C for 20min, take out deionized water and rinse, N 2 It blows dry, obtains the foamed copper that forms copper hydroxide on the surface;

[0019] (3) Soak the foamed copper after step 2 processing in Na 2 In S solution, soaked at room temperature 25°C for 24h, the Na 2 The concentration of S is 0.05mol / L, and the solvent is composed of deionized water and methanol according to the volume ratio of 1:1; then take it out and rinse it with deionized water, N 2 Blow dry to obtain foamed copper with cuprous sulfide on the surface.

[0020] (4) The copper foam tr...

Embodiment 2

[0025] Embodiment 2: the present embodiment studies the activation process, specifically as follows:

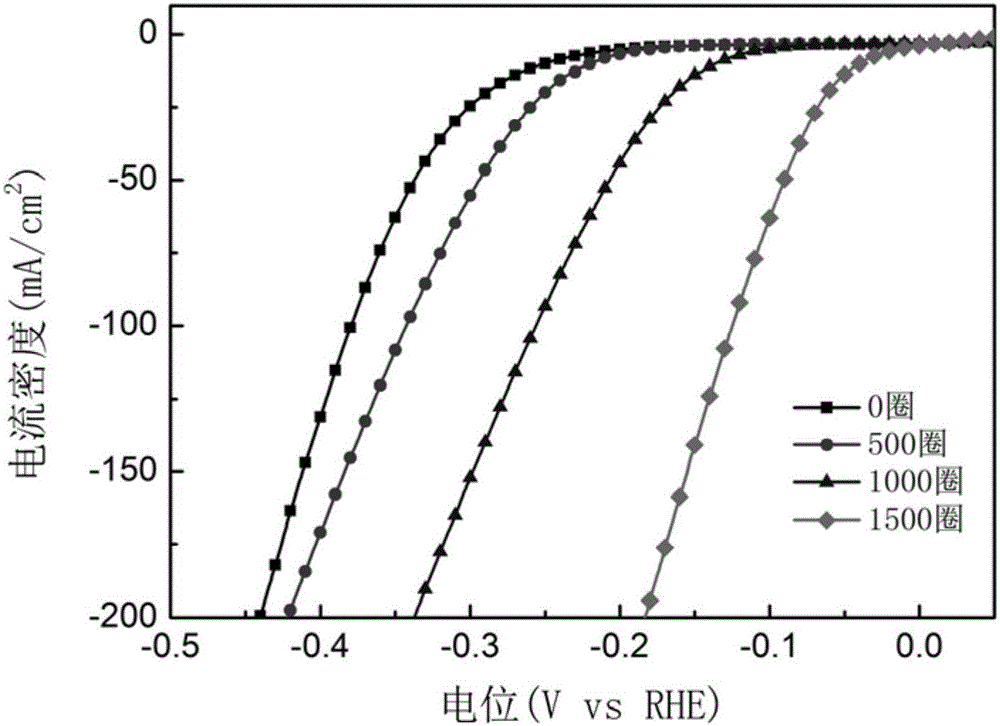

[0026]The copper foam loaded with cuprous sulfide on the surface is activated by electrochemical cyclic voltammetry cv to obtain sulfur-doped cuprous oxide converted from cuprous sulfide. The potential window of cv activation is 0.1V~-0.8V vs RHE, The scan rate is 100mV / s, the number of cycles is 1500, and the electrolyte is 0.5M H 2 SO 4 , the counter electrode is a Pt sheet.

[0027] Such as image 3 As shown, in the process of preparing sulfur-doped cuprous oxide three-dimensional nanoporous materials from cuprous sulfide by cyclic voltammetry, the polarization curves (Polarization curves) corresponding to 0 circles, 500 circles, 1000 circles, and 1500 circles respectively, It can be seen that as the number of cyclic voltammetry cycles increases, the catalytic performance of the material is gradually optimized, and the performance is stable after activation to 1500 cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com