Method for preparing porous titania bulk material by surface oxidation of porous titanium

A technology of porous titanium dioxide and bulk material, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of unused, cumbersome process, poor impact resistance, etc., and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

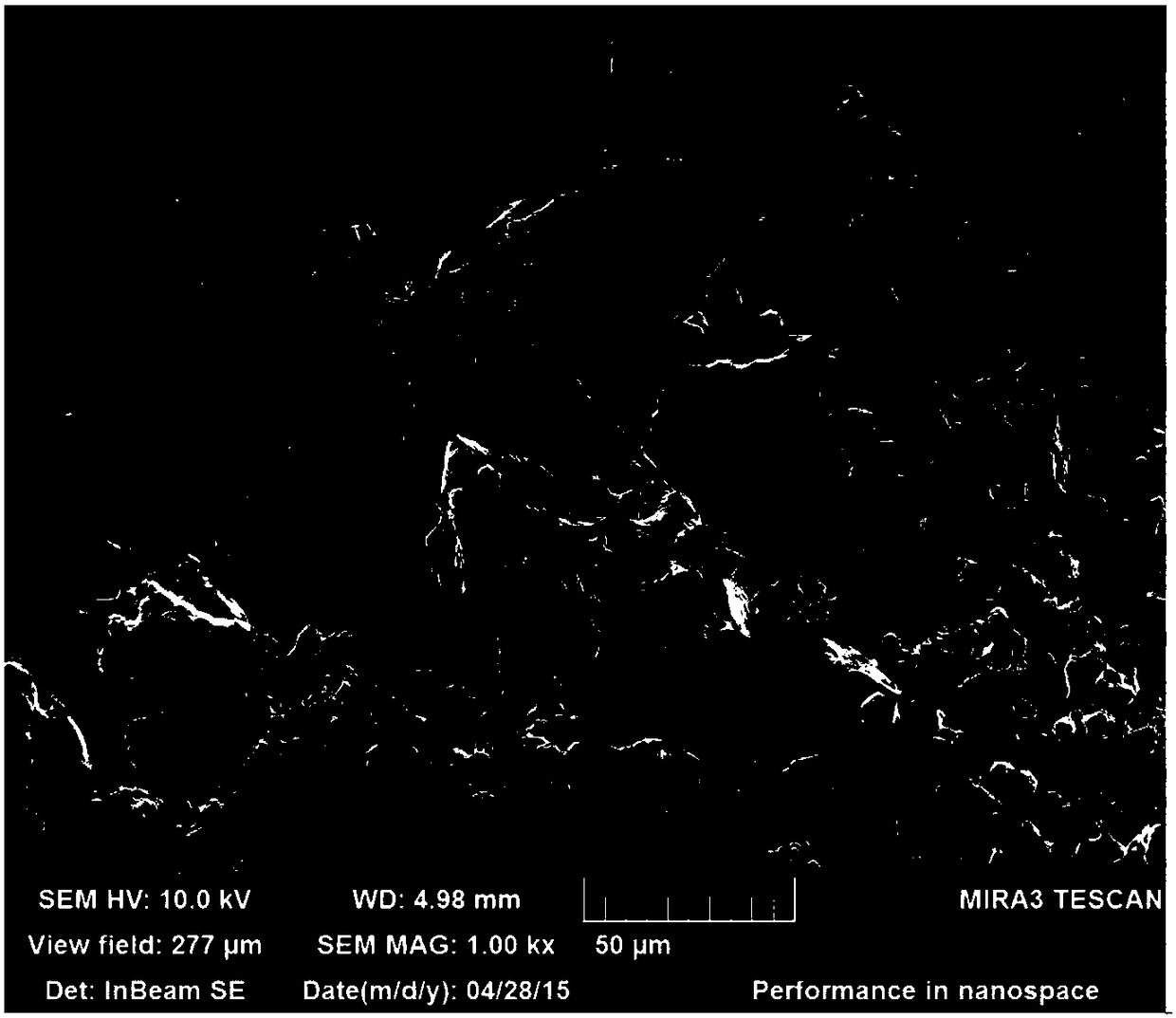

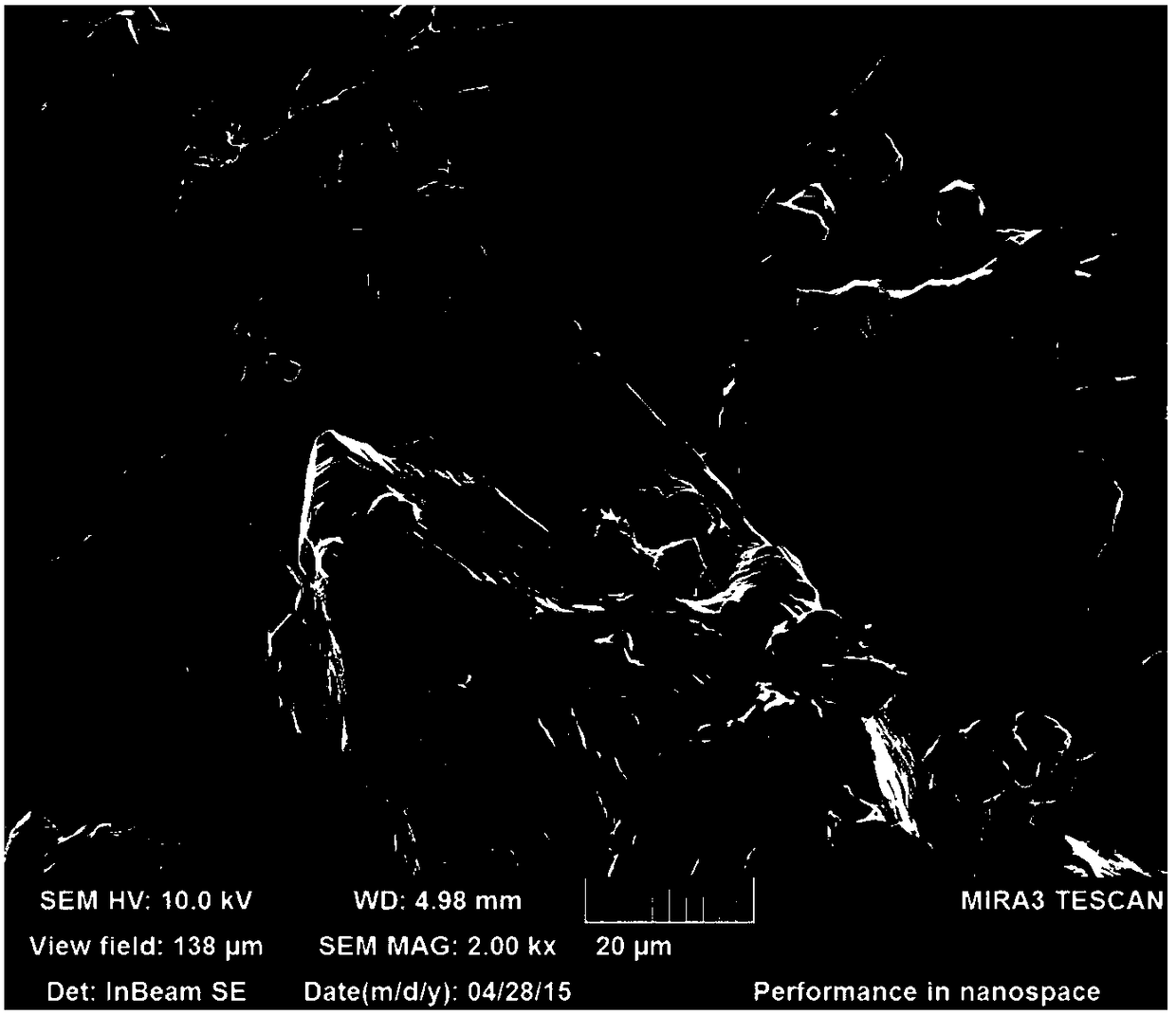

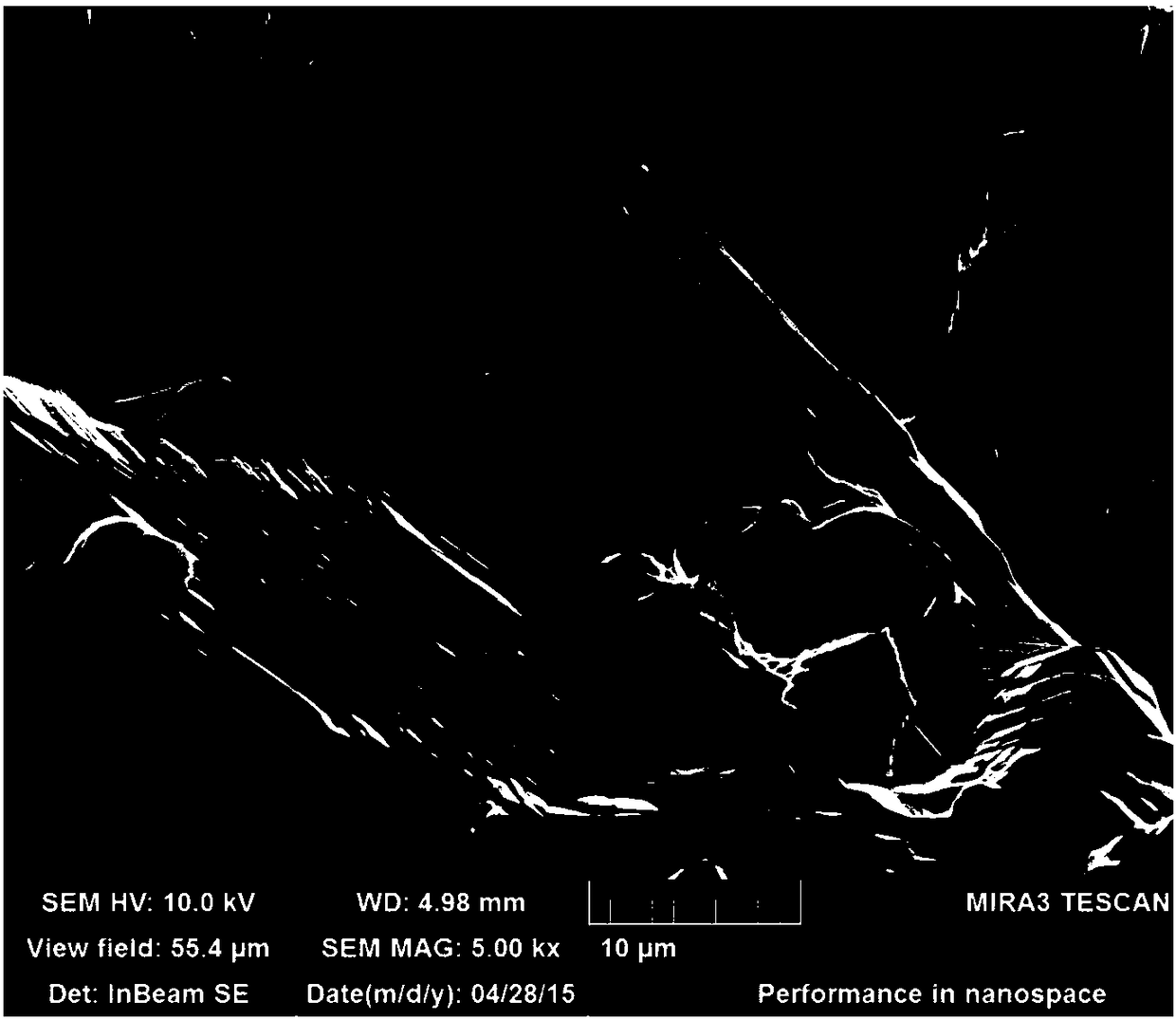

[0031] The specific technical solutions of the present invention are described in conjunction with the examples.

[0032]This material uses titanium powder with a purity of 99.98% as the raw material. According to the difference in porosity and strength of the prepared porous titanium, the diameter of the titanium powder can be selected from 0.5 to 100 μm. Naphthalene or ammonium bicarbonate with a purity of 99.97% is used as a pore-forming agent, such as naphthalene or ammonium bicarbonate, which is volatilized by thermal sublimation. After mechanical grinding, naphthalene particles of 1 to 500 μm are sieved according to the pore size requirements of the prepared material as a pore-forming agent. According to the different requirements of the material on the porosity, the pore-forming agent and titanium powder are mixed in a volume ratio of 1:10 to 1:1 and mixed mechanically. The uniformly mixed powder is put into a stainless steel mold lined with carbon paper and compacted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com