Method for synthesizing paraphthaloyl chloride (TPC) through continuous flow in micro-channel reactor

A technology of terephthaloyl chloride and microchannel reactor, which is applied in chemical instruments and methods, chemical/physical/physicochemical reactors, preparation of organic compounds, etc., can solve the problem of dark catalyst color, increase process steps, and recovery rate Low-level problems, to achieve the effect of low catalyst consumption, high reaction efficiency and stable catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

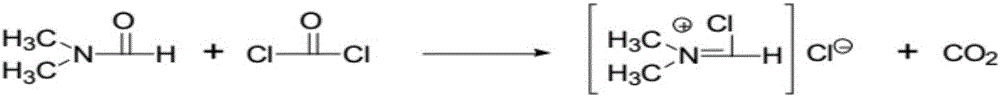

Method used

Image

Examples

Embodiment 1

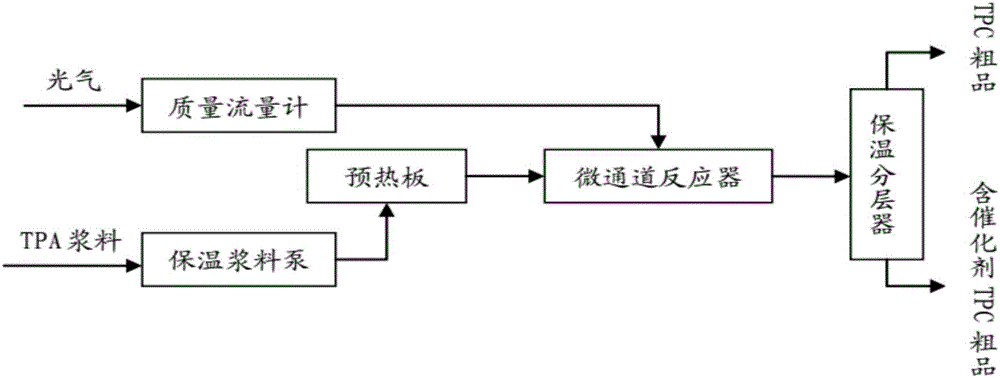

[0035] 1. Raw material preparation: Weigh 2000g of TPC, put it into a 2000ml four-neck bottle, heat and melt it in an oil bath at 90°C, then add 500g of TPA (screened with 200 mesh in advance), 10g of DMF, stir and mix to form a uniform slurry Standby; phosgene is connected to the microreactor through the pipeline through the mass flow meter, one-way valve, safety valve, etc. for standby.

[0036] 2. In the heart-shaped microchannel made of special glass, follow the steps below: (1) TPA slurry enters the microchannel reactor through the heat preservation slurry pump, opens the phosgene valve, and enters the microchannel reactor through the mass flow meter ; (2) Continuous flow microchannel reactor is adopted in the reaction process, raw material TPA homogeneous slurry and phosgene are mixed in the reactor according to the ratio, and the reaction is controlled at 100 ℃ by heat exchanger; (3) By adjusting the slurry pump Frequency and flow meter opening control the mol ratio of ...

Embodiment 2

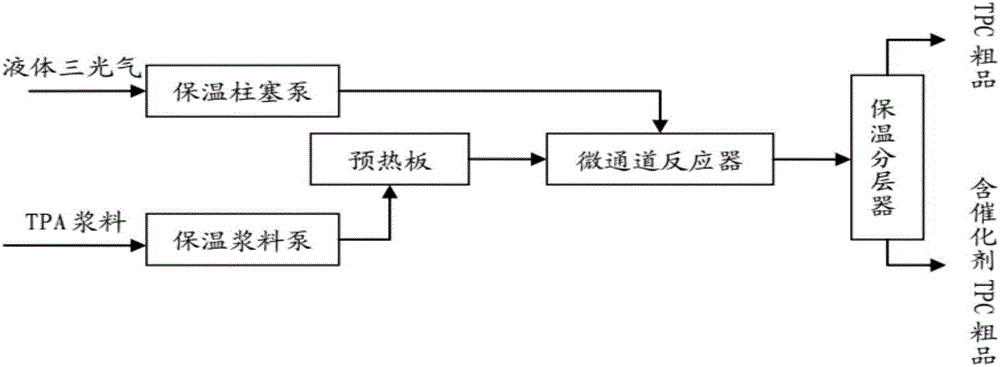

[0038]1. Raw material preparation: Weigh 2000g of TPC, put it into a 2000ml four-neck bottle, heat and melt it in an oil bath at 90°C, then add 500g of TPA (screened with 200 mesh in advance), 5g of DMF, stir and mix to form a uniform slurry Standby; phosgene is connected to the microreactor through the pipeline through the mass flow meter, one-way valve, safety valve, etc. for standby.

[0039] 2. In the heart-shaped microchannel made of special glass, follow the steps below: (1) TPA slurry enters the microchannel reactor through the heat preservation slurry pump, opens the phosgene valve, and enters the microchannel reactor through the mass flow meter ; (2) Continuous flow microchannel reactor is adopted in the reaction process, raw material TPA homogeneous slurry and phosgene are mixed in the reactor according to the ratio, and the reaction is controlled at 120 ℃ by heat exchanger; (3) By adjusting the slurry pump Frequency and flow meter opening control the mol ratio of TP...

Embodiment 3

[0041] 1. Raw material preparation: Weigh 2000g of TPC, put it into a 2000ml four-neck bottle, heat and melt it in an oil bath at 90°C, then add 500g of TPA (screened with 200 mesh in advance), 5g of DMF, stir and mix to form a uniform slurry Standby; phosgene is connected to the microreactor through the pipeline through the mass flow meter, one-way valve, safety valve, etc. for standby.

[0042] 2. In the heart-shaped microchannel made of special glass, follow the steps below: (1) TPA slurry enters the microchannel reactor through the heat preservation slurry pump, opens the phosgene valve, and enters the microchannel reactor through the mass flow meter ; (2) Continuous flow microchannel reactor is adopted in the reaction process, raw material TPA homogeneous slurry and phosgene are mixed in the reactor according to the ratio, and the reaction is controlled at 120 ℃ by heat exchanger; (3) By adjusting the slurry pump Frequency and flow meter opening control the mol ratio of T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com