Fire retardant coating and production method thereof

A technology of fireproof coatings and raw materials, applied in the field of coatings, can solve the problems of coatings such as high temperature resistance, adhesion, weather resistance, and fire resistance time are not ideal, and achieve the protection of life and property safety, excellent adhesion performance, and excellent high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

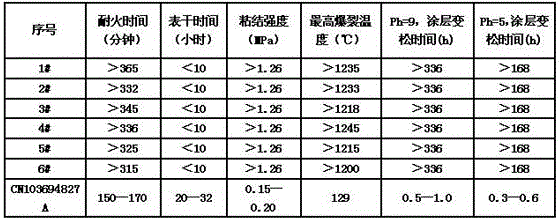

Examples

Embodiment 1

[0015] A fireproof coating, which is composed of the following raw materials in parts by weight: asbestos powder with a fineness of less than 200 mesh: 10 parts, mica powder with a fineness of less than 200 mesh: 10 parts, zirconium dioxide: 12 parts, silicon dioxide: 12 parts Parts, boron trioxide: 10 parts, aluminum silicate: 3 parts, titanium dioxide: 6 parts, ammonium polyphosphate: 10 parts, aluminum hydroxide: 10 parts, pentaerythritol: 2 parts, chlorinated paraffin: 1 part, poly Vinyl chloride resin: 10 parts, polyacrylamide: 6 parts, dioctyl phthalate: 1 part, melamine urea-formaldehyde resin: 8 parts, calcium carbonate: 15 parts, sodium polynaphthalene sulfonate: 2 parts, OP-100 Emulsifier: 1 part, tetramethrin: 2 parts, pine oil: 1 part, tap water: 30 parts.

Embodiment 2

[0017] A fireproof coating, which is composed of the following raw materials in parts by weight: asbestos powder with a fineness of less than 200 mesh: 20 parts, mica powder with a fineness smaller than 200 mesh: 20 parts, zirconium dioxide: 18 parts, silicon dioxide: 16 parts Parts, boron trioxide: 16 parts, aluminum silicate: 5 parts, titanium dioxide: 8 parts, ammonium polyphosphate: 20 parts, aluminum hydroxide: 15 parts, pentaerythritol: 6 parts, chlorinated paraffin: 3 parts, poly Vinyl chloride resin: 18 parts, polyacrylamide: 8 parts, dioctyl phthalate: 3 parts, melamine urea-formaldehyde resin: 16 parts, calcium carbonate: 25 parts, sodium polynaphthalene sulfonate: 4 parts, OP-100 Emulsifier: 3 parts, tetramethrin: 4 parts, pine oil: 3 parts, tap water: 50 parts.

Embodiment 3

[0019] A fireproof coating, which is composed of the following raw materials in parts by weight: asbestos powder with a fineness of less than 200 mesh: 15 parts, mica powder with a fineness of less than 200 mesh: 15 parts, zirconium dioxide: 16 parts, silicon dioxide: 14 parts Parts, boron trioxide: 13 parts, aluminum silicate: 4 parts, titanium dioxide: 7 parts, ammonium polyphosphate: 15 parts, aluminum hydroxide: 12.5 parts, pentaerythritol: 4 parts, chlorinated paraffin: 2 parts, poly Vinyl chloride resin: 14 parts, polyacrylamide: 7 parts, dioctyl phthalate: 2 parts, melamine urea-formaldehyde resin: 24 parts, calcium carbonate: 20 parts, sodium polynaphthalene sulfonate: 3 parts, OP-100 Emulsifier: 2 parts, tetramethrin: 3 parts, pine oil: 2 parts, tap water: 40 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com