A powder pre-layered composite electroforming device

A layered, powder technology, applied in electroforming, electrolysis process, etc., can solve problems such as low efficiency, and achieve the effect of simple process, low preparation cost and dense crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

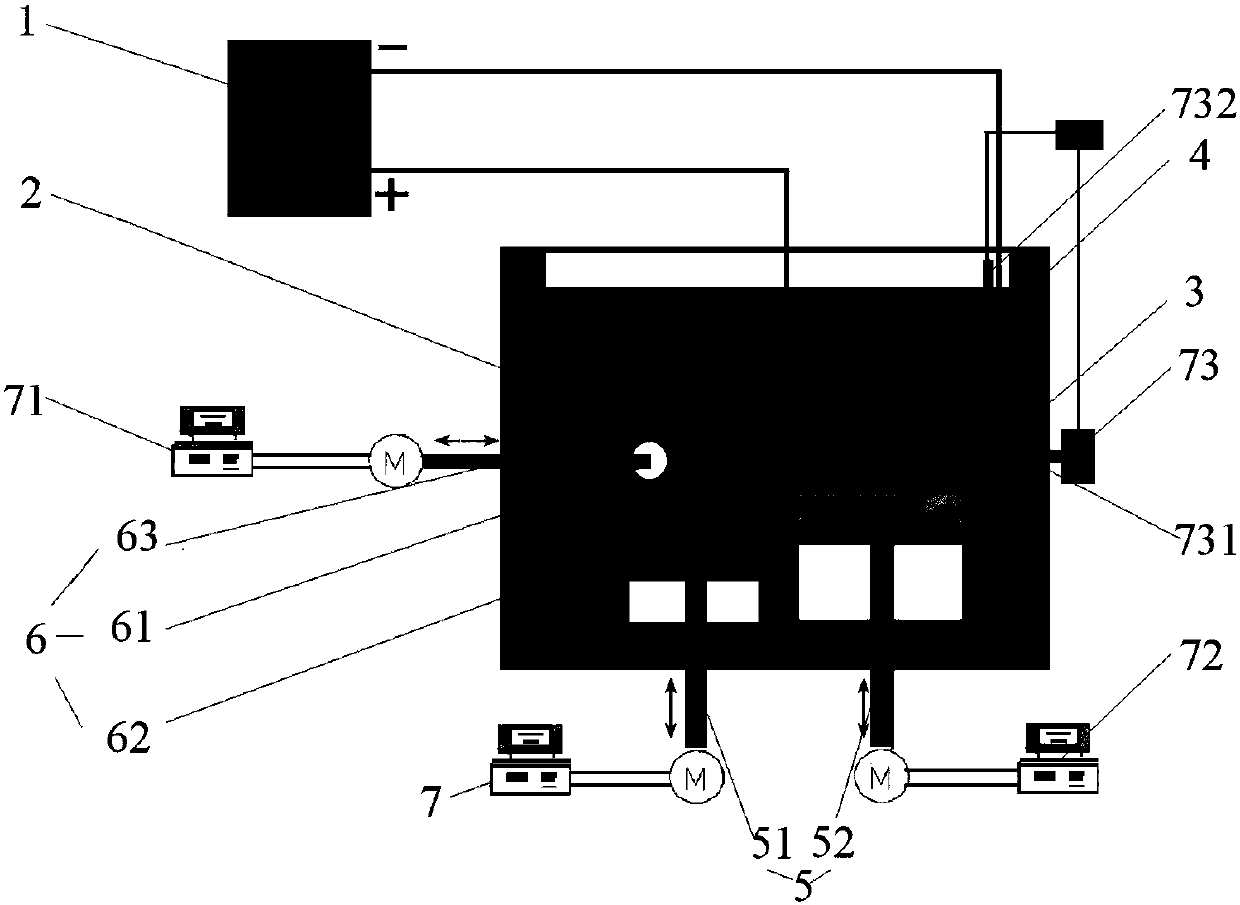

Method used

Image

Examples

Embodiment 1

[0031] The specific steps of using the device of the invention to prepare metal and alloy materials include pretreatment of metal powder, preparation of electrolyte, initial treatment of cathode plate, pre-laying of powder, and electrodeposition forming.

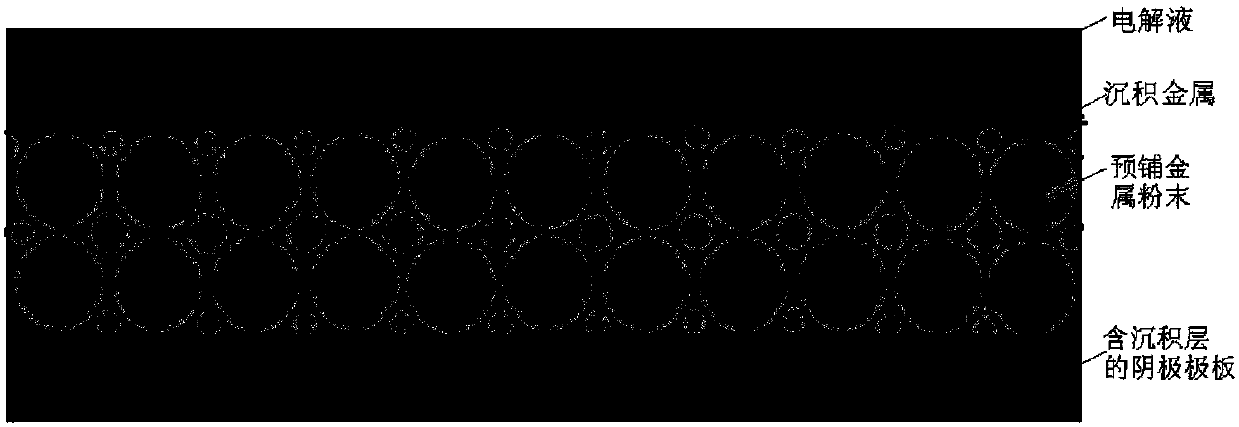

[0032] (1) Pretreatment of metal powder. ①In order to increase the compaction density of the powder, a wider powder particle size range (2μm~50μm) is used, powder particles of different particle sizes are used, and small particle powder is used to fill the gaps between large particles, so as to improve the bulk density and compaction of the powder. Solid density, reduce the amount of metal deposition during electroforming, and increase the forming rate of electroforming; ② In order to improve the surface activity of the powder, the powder is ball milled, and the ball mill is wet milled for 2 hours with ethanol as the ball milling medium; ③ Wetting treatment and removal The method of surface oil pollution is to soak the metal...

Embodiment 2

[0038] In this example:

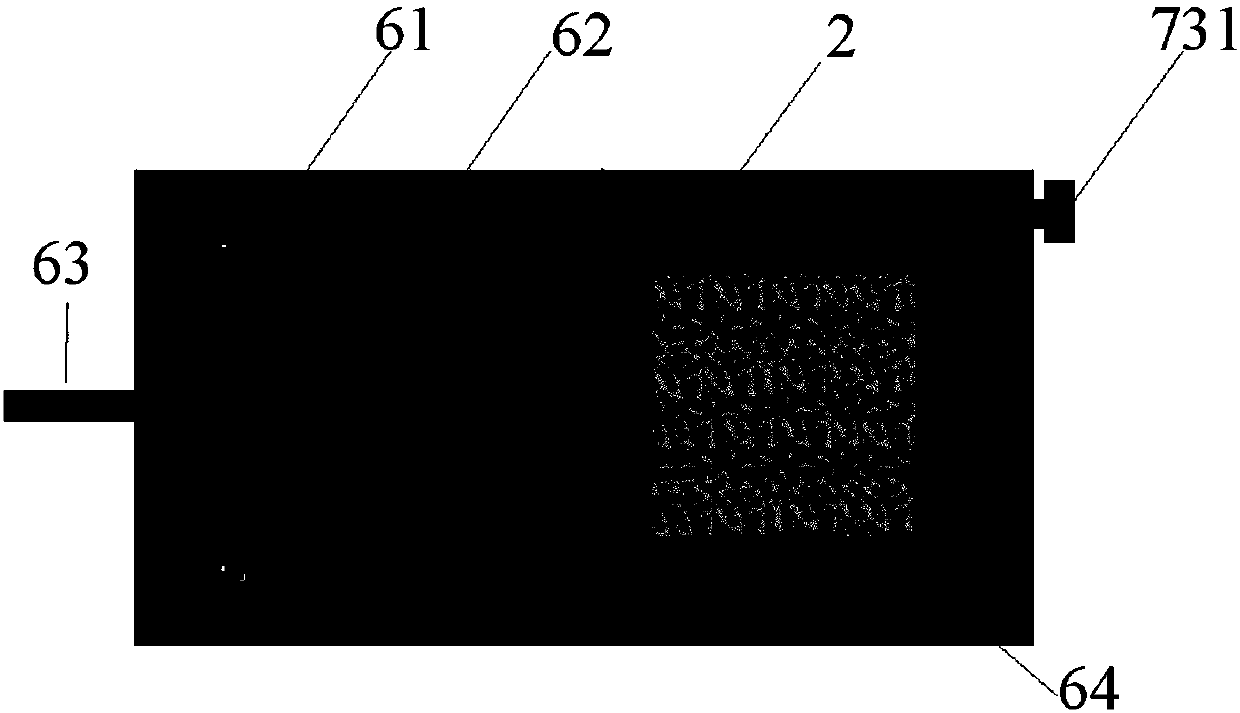

[0039] The cathode base material is copper sheet, the size is 50mm×50mm×2mm;

[0040] The anode material is a nickel plate with a purity of more than 99.9%, and the shape is 50mm×50mm×5mm. The cathode and anode are parallel and opposed to each other immersed in the electrolyte, and the distance between the cathode and the anode is between 50mm;

[0041] The anode nickel is flat, the cathode copper sheet is also flat, the cathode and anode are kept parallel, and the pre-coated nickel powder is also kept parallel, parallel to the surface of the cathode and anode, and the layers ensure that the electrodeposition rate of the cathode surface is equal, and the deposited layer Uniform thickening;

[0042] The electroforming system uses electric heating tubes for heating, and the temperature control system realizes that the temperature can be adjusted between room temperature and 80°C, and the temperature adjustment accuracy is 0.5°C;

[0043] In this example...

Embodiment 3

[0051] The power supply of the present invention can adopt a pulse power supply to carry out plasma electroforming; the push rod of the powder spreading wheel shaft of the powder spreading device of the present invention and the side wall of the deposition chamber adopt clearance fit, the side wall of the material storage chamber, and the side wall of the deposition chamber Made of glass, the push plate of the powder lifting device of the storage chamber and the cathode lifting device of the deposition chamber are made of heat-resistant plexiglass, the push plate of the powder lifting device of the storage chamber and the side wall of the storage chamber adopt clearance fit, The push plate of the lifting device and the side wall of the deposition chamber adopt a gap fit to prevent the electrolyte from flowing out; The gap fit is used between the holes; the heat-resistant plexiglass material is used to meet the characteristics of high voltage, corrosion of electrolyte and high t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com