Surface electrode silver paste for chip type resistor and preparation method for surface electrode silver paste

A surface electrode and resistance technology, which is applied in the field of surface electrode silver paste for chip resistors and its preparation, can solve the problem of resistance accuracy, working voltage temperature coefficient, and voltage coefficient stability not meeting the requirements, irreplaceable, and backward technology, etc. Problems, achieve good solderability and low contact resistance characteristics, anti-discoloration ability of silver layer, and improve the effect of silver layer strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

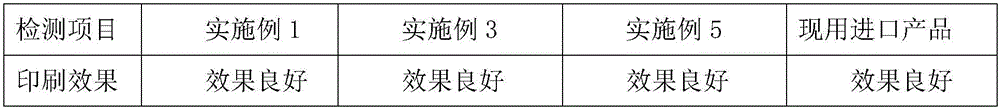

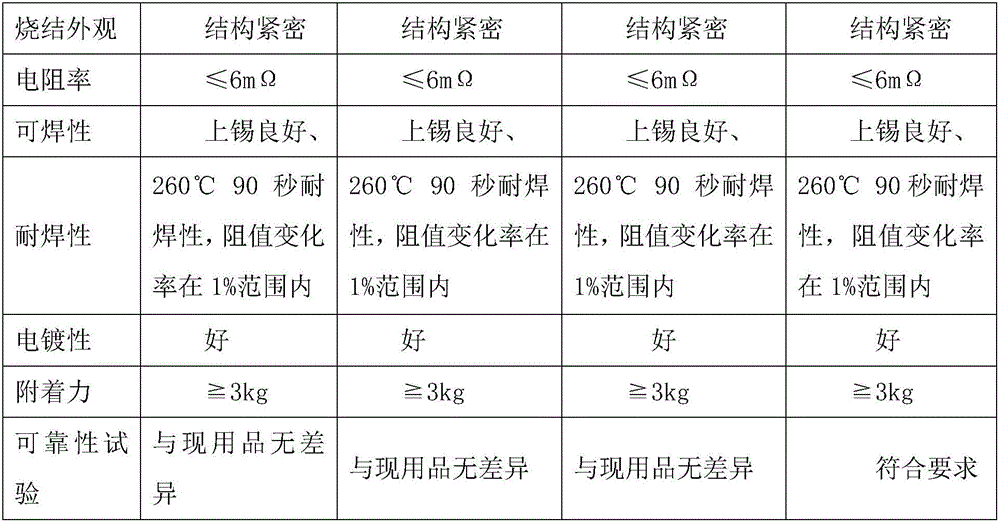

Examples

Embodiment 1

[0040]The surface electrode silver paste for chip resistors of this embodiment is made up of the following raw materials in weight percent: silver powder with a particle size less than 5 μm: 70%; palladium powder: 0.5%; metal powder: 1.5%; glass powder: 5%; organic carrier: twenty three%. Among them, the purity of the silver powder is greater than 99.9%, calculated as a percentage of the total weight of the silver paste for the surface electrode of the chip resistor, and consists of the following components: 52% of spherical silver powder with a particle size of 0.5-3.0 μm; Shape silver powder 14%; Nano silver powder 4%. Palladium powder is pure palladium powder, its particle size D 90 0.1 to 0.8 μm. The metal powder is copper powder with a particle size of 0.5-3.0 μm. Glass powder, B without lead and cadmium 2 o 3 -SiO 2 -Bi 2 o 3 -TiO 2 Glass system, particle size less than 5μm, D 50 1.0~2.0μm, glass softening temperature is 650~750℃, converted into oxides, includi...

Embodiment 2

[0042] The surface electrode silver paste for chip resistance of embodiment 1, its preparation method is as follows:

[0043] (1) Preparation of glass powder

[0044] B by weight percentage 2 o 3 10%, SiO 2 10%, Bi 2 o 3 51%, TiO 2 20%, Al 2 o 3 5%, La 2 o 3 2%, CaO 1.5%, and ZnO 0.5% are mixed evenly with a pot mill, preheated at 450°C for 20 minutes, melted at 1300°C for 60 minutes, quenched, ball milled until the particle size is less than 5 μm, filtered and dried, and set aside;

[0045] (2) Preparation of organic carrier

[0046] 18% of ethyl cellulose, 32% of terpineol, 20% of diethylene glycol butyl ether, 20% of DuPont DBE mixed dibasic acid dimethyl ester, 5% of lecithin, and 5% of polyacrylate by mass percentage After mixing, heat and dissolve completely in a water bath at 90-100°C, and filter through 300 mesh to obtain a transparent glue;

[0047] (3) Preparation of surface electrode silver paste for chip resistors

[0048] 52% spherical silver powde...

Embodiment 3

[0050] The surface electrode silver paste for chip resistors of this embodiment is made up of the following raw materials in weight percent: silver powder with a particle size less than 5 μm: 68%; palladium powder: 1%; metal powder: 1%; glass powder: 6%; organic carrier: twenty four%. Among them, the purity of the silver powder is greater than 99.9%, calculated as a percentage of the total weight of the silver paste for the surface electrode of the chip resistor, and consists of the following components: 50% of spherical silver powder with a particle size of 0.5-3.0 μm; Shape silver powder 15%; Nano silver powder 3%. Palladium powder is pure palladium powder, its particle size D 90 0.1 to 0.8 μm. The metal powder is titanium powder with a particle size of 0.5-3.0 μm. Glass powder, B without lead and cadmium 2 o 3 -SiO 2 -Bi 2 o 3 -TiO 2 Glass system, particle size less than 5μm, D 50 1.0~2.0μm, glass softening temperature is 650~750℃, converted into oxides, including...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com