Biocorrosion Inhibitors for Metals

A bio-corrosion and inhibitor technology, applied in biocides, animal repellents, plant growth regulators, etc., can solve the problem that the mechanism of occurrence is not elucidated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

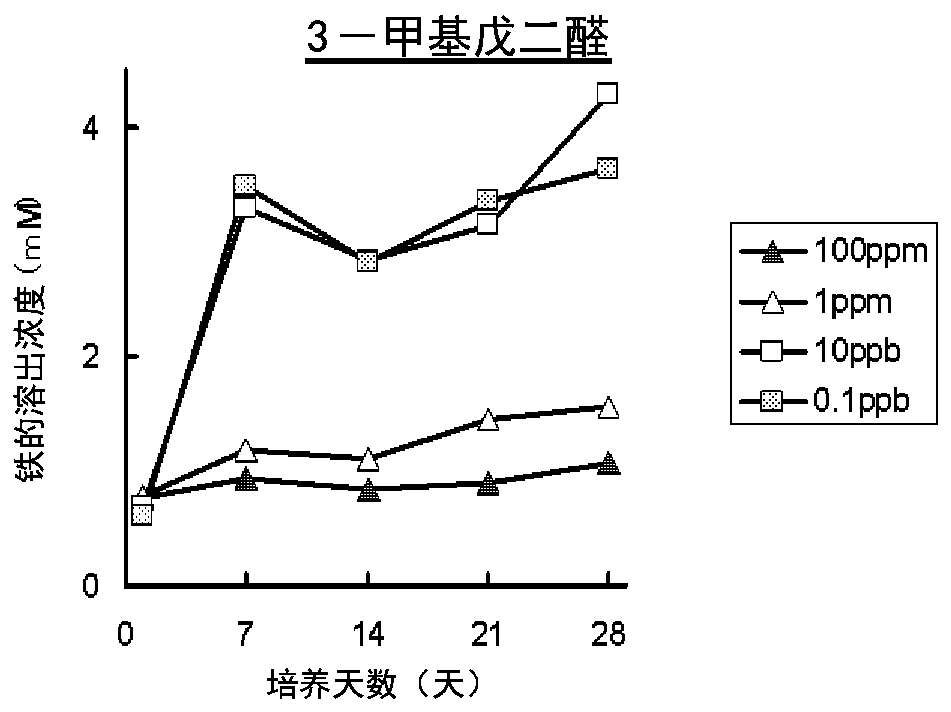

[0083] For 3-methylglutaraldehyde, the biocorrosion inhibition test was performed as described above.

[0084] [Preparation of inorganic salt seawater culture medium (A solution)]

[0085] Milli-Q water 970ml, NaCl 19.0g, MgCl 2 ·6H 2 O 2.6g, CaCl 2 ·2H 2 O 0.15g, Na 2 SO 4 4.0g, NH 4 Cl 0.25g, KH 2 PO 4 4.0g, KCl 0.5g, HEPES (2-[4-(2-hydroxyethyl)-1-piperazinyl]ethanesulfonic acid) 23.8g were mixed and dissolved in an anaerobic chamber to prepare inorganic salt seawater culture Base (Liquid A).

[0086] In addition, Milli-Q water is ultrapure water produced using the apparatus (for example, Milli-Q Integral10) manufactured by Merk Millipore.

[0087] [Preparation of sodium bicarbonate solution (liquid C)]

[0088] Dissolve NaHCO in Milli-Q water 30ml 3 After 2.52 g, filter sterilization was performed to prepare a sodium bicarbonate solution (C solution).

[0089] [Preparation of trace element solution (E solution)]

[0090] 8.3ml of HCl (35%), FeSO 4 ·7H 2 O...

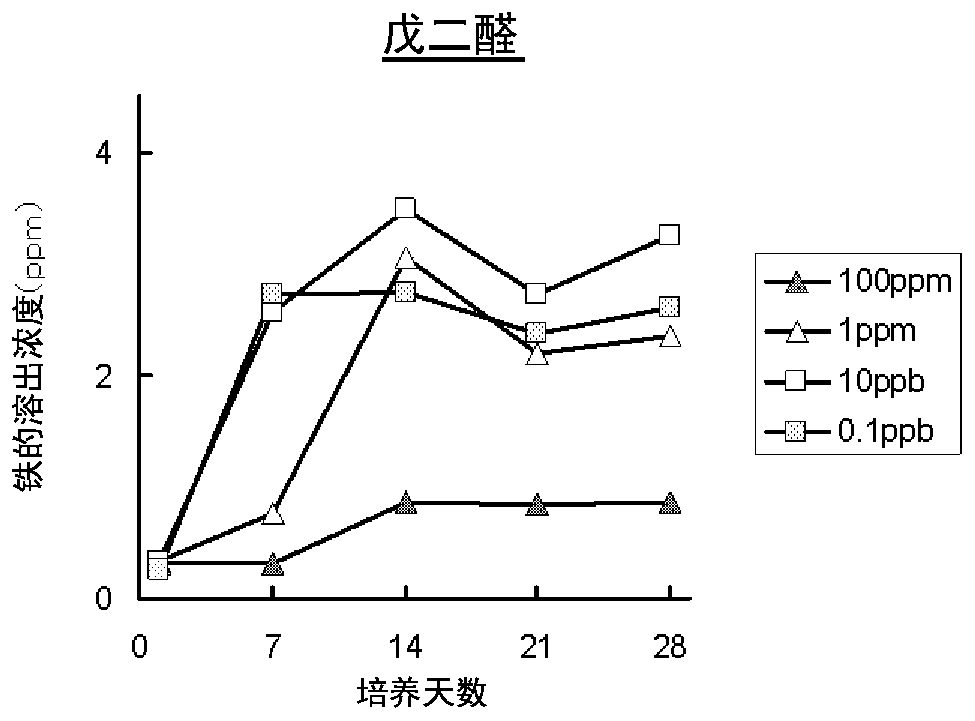

Embodiment 2

[0101] About 3-methylglutaraldehyde and glutaraldehyde, the biodegradability test was carried out as follows.

[0102]

[0103] Referring to the test methods of OECD test guideline 301C (OECD test guideline 301C) and JIS K 6950 (ISO 14851), the decomposition degree test of the test substance was carried out. That is, 300 ml of inorganic culture medium was added to the culture flask, and 9 mg (30 ppm) of activated sludge obtained from the Mizushima sewage treatment plant in Mizushima area, Kurashiki City, Okayama Prefecture, Japan, on the day of the test was started. Because of the bactericidal effect and the effect on the sludge, the biodegradability test was performed at two concentrations of the high concentration group: 30 mg (100 ppm) of the substance to be tested, and the low concentration group: 9 mg (30 ppm).

[0104] After culturing at 25°C for 28 days using a coulomb meter (Okura Electric Model 3001A), the biodegradation rate was calculated using the amount of oxyge...

Embodiment 3

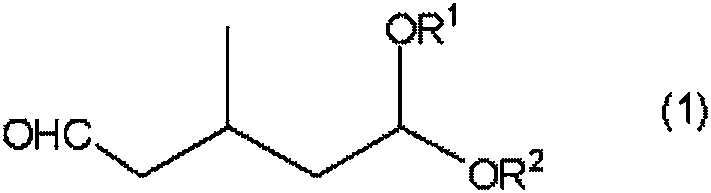

[0113] 2.0 g of an acetal compound represented by the following formula (hereinafter, referred to as acetal compound A) was added to 100 g of an aqueous hydrochloric acid solution prepared by adding hydrochloric acid to distilled water to adjust the pH to 4.0, and the reaction was carried out at 80° C. under a nitrogen atmosphere. Stir. One hour later, a part was collected and analyzed by gas chromatography. As a result, it was confirmed that 97.2% of the acetal compound A was consumed and 82.6% of 3-methylglutaraldehyde was produced.

[0114] [Chemical formula 5]

[0115]

[0116] [Gas chromatography analysis conditions]

[0117] Analysis equipment: GC-2014 (manufactured by Shimadzu Corporation)

[0118] Detector: FID (Hydrogen Flame Ionization Detector)

[0119] Column used: DB-WAX (length 30m, film thickness 0.25μm, inner diameter 0.25mm)

[0120] (manufactured by Agilent Technologies Japan, Ltd.)

[0121] Analysis conditions: gasification chamber temperature 250°C, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com