A kind of sulfonium salt type dispersion resin for cathodic electrophoretic coating and preparation method thereof

A cathodic electrophoretic coating and dispersing resin technology, applied in the coating field, can solve the problems of poor appearance of the paint film, and achieve the effects of low VOC content, easy large-scale operation and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of component A of cathodic electrophoretic paint—emulsion.

[0040] For the preparation method, reference may be made to the methods described in US8486538B2, US4419467, and US3984299.

[0041] Prepare the following components in parts by weight: 816 parts of epoxy resin 828, 2 parts of methyltriphenylphosphonium iodide catalyst, 384 parts of bisphenol A, 60 parts of xylene, 847 parts of blocked isocyanate crosslinking agent ( Prepared by reacting toluene diisocyanate with isooctyl alcohol and trimethylolpropane, the molar ratio of isooctyl alcohol to trimethylolpropane is 7:3, the solid content is 85%), 45 parts of N-methyl monoethanolamine, 144 Parts of ketimine (made by dehydration reaction of diethylenetriamine and methyl isobutyl ketone, solid content 85%), 120 parts of propylene glycol n-butyl ether, 60 parts of propylene glycol phenyl ether, 24 parts of glacial acetic acid, 3500 parts parts deionized water.

[0042] Under the protection o...

Embodiment 2

[0043] Example 2: Preparation of sulfonium salt type dispersion resin.

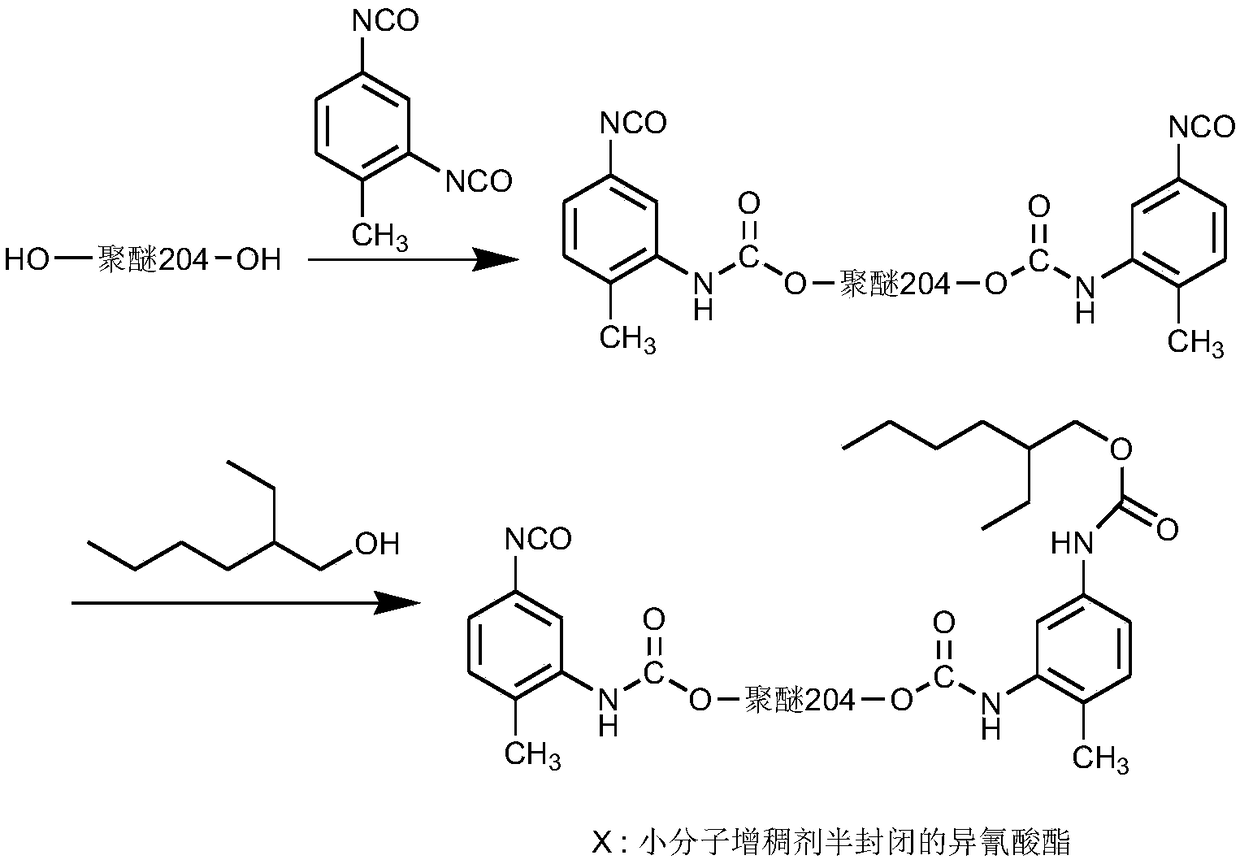

[0044] (1) Prepare the following components in parts by weight: 174 parts of 2,4-toluene diisocyanate (molecular weight 174g / mol), 200 parts of polyether 204 (average molecular weight 400g / mol), 90 parts of methyl isobutyl Base ketone, 130 parts of isooctyl alcohol (molecular weight 130g / mol);

[0045] Such as figure 1 As shown, under the protection of nitrogen, add 2,4-toluene diisocyanate into a four-neck flask with a stirrer, circulating cooling water and a high level tank, and control the speed at 400rpm; add polyether 204 dropwise, and turn on the cooling circulating water at the same time After 3 hours of dropping, keep warm at 30°C for 2 hours; add isooctyl alcohol dropwise, finish dropping in 2 hours, keep warm at 30°C for 3 hours; add methyl isobutyl ketone, stir well, and get small molecule thickening semi-blocked isocyanate ( figure 1 and Figure 4 X component in), spare.

[0046] (2) Prep...

Embodiment 3

[0052] Example 3: Preparation of component B of cathodic electrophoretic paint—color paste.

[0053] Prepare the following components in parts by weight: 314 parts of sulfonium salt type dispersion resin prepared in Example 2, 460 parts of deionized water, 260 parts of china clay, 40 parts of carbon black, 8 parts of bismuth oxide and 1 part of Surfynol104E Type wetting agent (produced by Air Products Co., Ltd. of the United States);

[0054] Add deionized water to the reaction vessel with a high-speed stirring device, and control the speed at about 1200rpm; add sulfonium salt type dispersion resin and disperse evenly; add china clay, carbon black, bismuth oxide and Surfynol 104E wetting agent and mix evenly Grinding with a high-speed grinder, controlling the rotational speed at about 3000rpm, grinding for 2 hours until the fineness is less than 20 microns, and obtaining the color paste for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com