A method for amine-assisted low-temperature synthesis of porous boron nitride

A technology of boron nitride and low temperature, which is applied in the fields of chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as the inability to obtain boron nitride, achieve the effects of reducing calcination temperature, lowering synthesis temperature, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 1 g of ammonia borane in an Erlenmeyer flask containing 40 mL of 1,4-dioxane solution, stir until all the solids are dissolved, and transfer to the inner polytetrafluoroethylene container of the reaction kettle for use;

[0028] (2) Dissolve 0.1 g of octadecylamine in an Erlenmeyer flask containing 20 mL of 1,4-dioxane solution, ultrasonically disperse until clear, and set aside;

[0029] (3) The solution prepared in step (2) is added to the inner sleeve polytetrafluoroethylene container of the reaction kettle of step (1) to obtain the mixed solution of ammonia borane-octadecylamine, and the reaction kettle is put into a 160° C. In an oven, the airtight reaction (i.e. solvothermal reaction under saturated vapor pressure) was performed for 12 hours;

[0030] (4) The stock solution was allowed to stand at room temperature for 12 hours, then centrifuged, and the resulting precipitate was dried at 80°C for 5 hours to obtain a white powder;

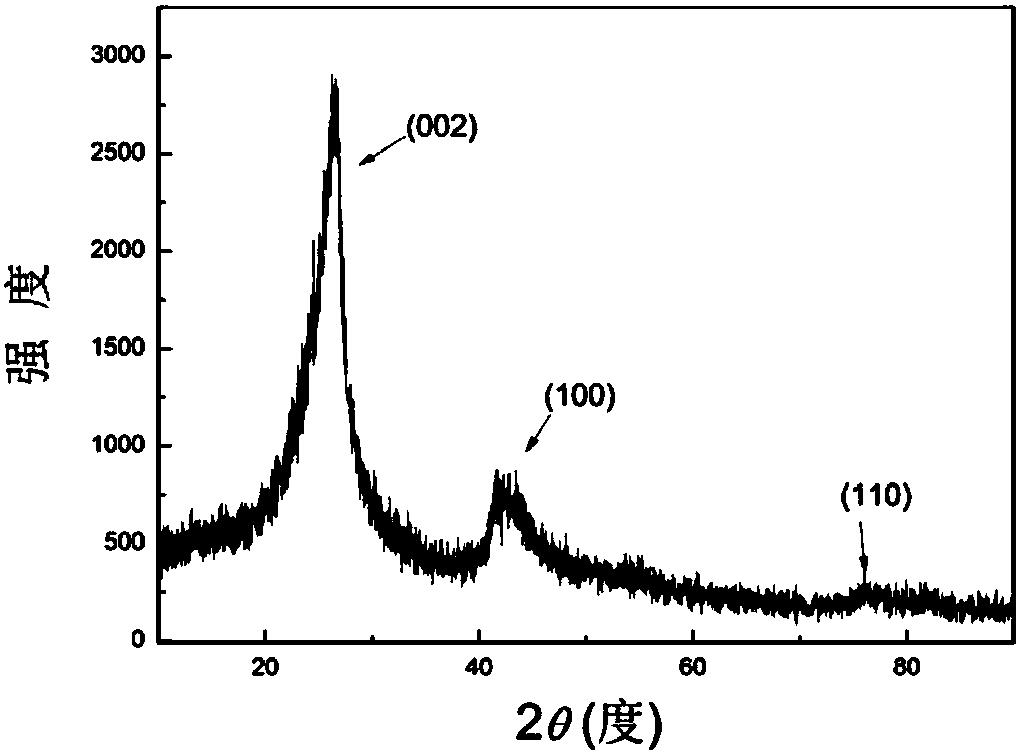

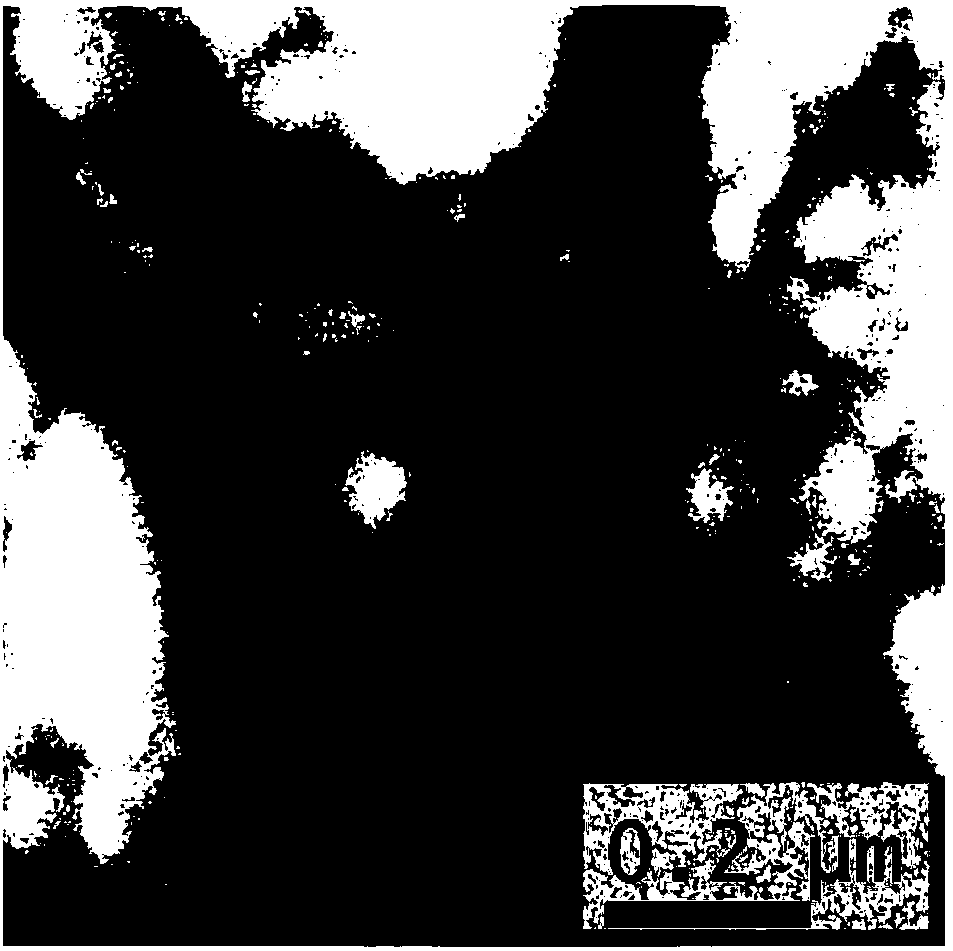

[0031] (5) The whi...

Embodiment 2

[0034] The octadecylamine consumption in the step (2) in the embodiment 1 is reduced to 0.025g, and other steps are with embodiment 1. Obtain product with embodiment 1.

Embodiment 3

[0036] The amount of octadecylamine in step (2) in Example 1 is increased to 0.5g, and other steps are the same as in Example 1. Obtain product with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com