Anti-pollution oil-water separation mesh film and preparation method thereof

An oil-water separation omentum and anti-pollution technology, applied in separation methods, immiscible liquid separation, liquid separation, etc., can solve the problems of strict preparation requirements, complicated process, poor anti-pollution effect, etc., and achieve good separation effect , simple process, good oil-water separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

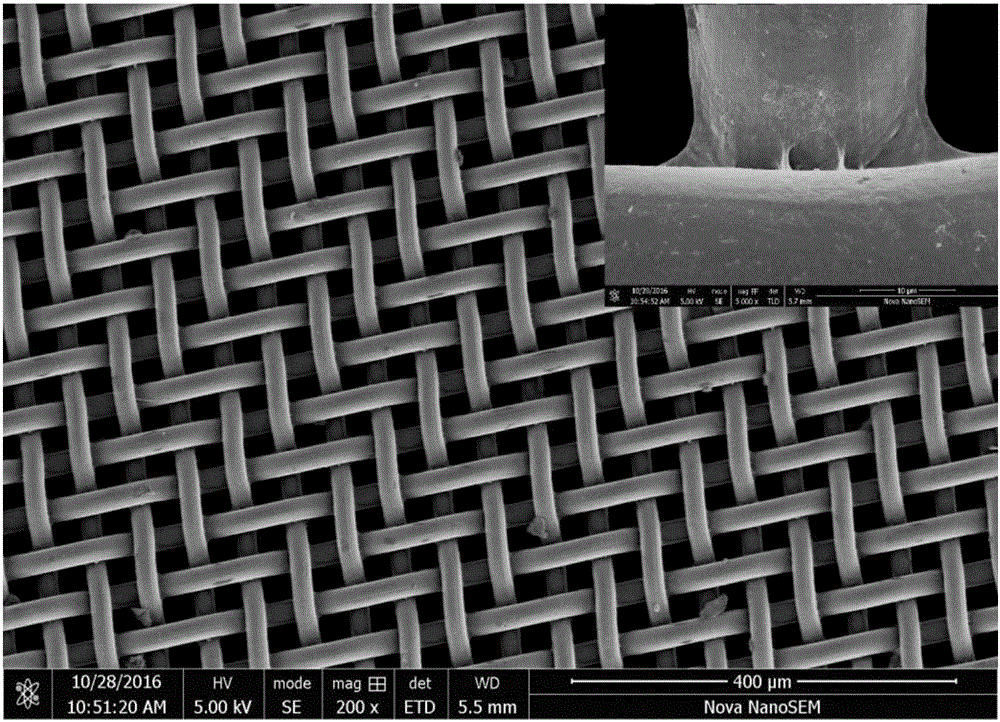

[0030] (1) The 100-mesh stainless steel mesh was first immersed in ethanol and ultrasonically cleaned for 5 minutes, then soaked in acetic acid aqueous solution for 5 minutes to remove impurities and particles on the surface, increase its roughness, and dry at room temperature;

[0031] (2) At room temperature, add 24g of dimethyl sulfoxide, 1g of polyacrylic acid, 0.1g of N,N-methylene bisacrylamide, 1g of polyoxyethylene polyoxypropylene ether block copolymer into a 100ml beaker, and magnetically stir , the stirring time is 1h, the stirring rate is 300r / min, and the cross-linked product is obtained at 40°C, and the mass percentage content of polyacrylic acid in the obtained mixed solution is 4%;

[0032] (3) Dip the stainless steel net cleaned in step (1) into the mixed solution obtained in step (2), keep it for 30s, and then take it out to dry at 40°C;

[0033] The stainless steel mesh membrane obtained in step (3) is an anti-pollution oil-water separation mesh membrane wit...

Embodiment 2

[0036] (1) The 400-mesh iron mesh was first immersed in ethanol for 5 minutes, and then soaked in acetic acid aqueous solution for 5 minutes to remove impurities and particles on the surface, increase its roughness, and dry at room temperature;

[0037] (2) At room temperature, add 23g of styrene, 2g of polyvinyl alcohol, 0.2g of 2,2-bis[4-(2,3-epoxypropoxy)phenyl]propane, 2g of fat in a 100ml beaker Alcohol polyoxyethylene ether sodium sulfate, magnetically stirred, the stirring time is 3h, the stirring rate is 800r / min, and the cross-linked product is obtained at 60°C, and the mass percentage of polyvinyl alcohol in the obtained mixed solution is 8%;

[0038] (3) Dip the iron net obtained in step (1) into the mixed solution obtained in step (2), keep it for 0.5h, and then take it out to dry at 60°C;

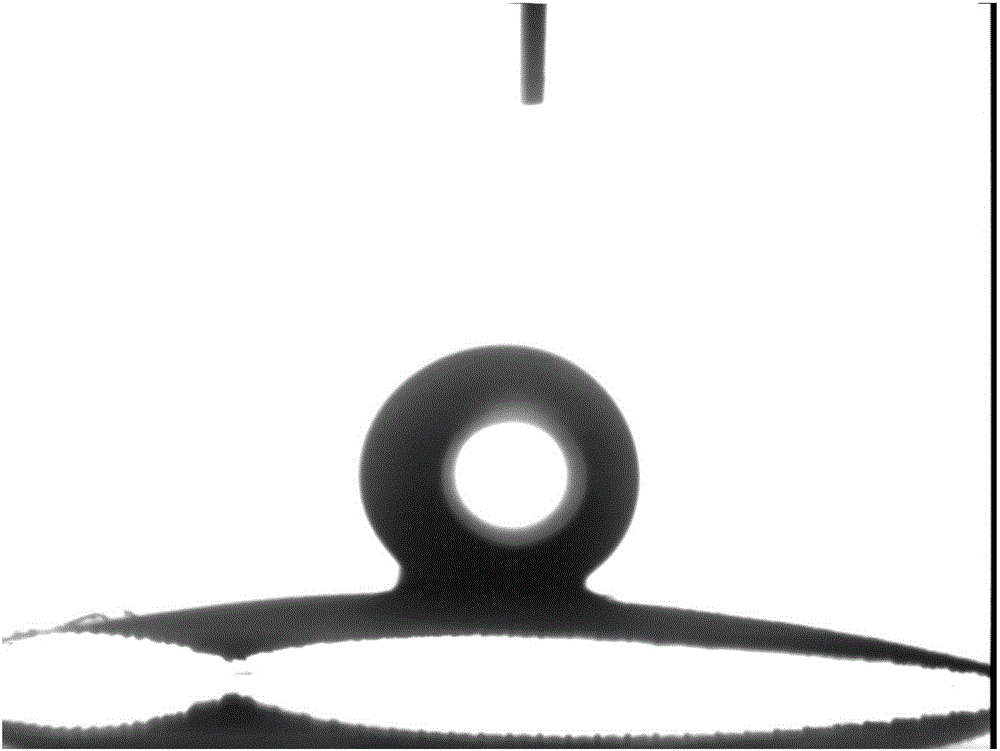

[0039] (4) The surface of the iron net obtained in step (3) forms a polymer coating layer with a thickness of 1 micron, which has a bubble structure with a nanometer-sized widt...

Embodiment 3

[0041] (1) The 1000-mesh copper mesh was first immersed in ethanol for 5 minutes, and then soaked in acetic acid aqueous solution for 5 minutes to remove impurities and particles on the surface, increase its roughness, and dry at room temperature;

[0042] (2) At room temperature, add 22g of trichlorethylene, 3g of polyvinyl chloride resin, 0.3g of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 3g of heavy alkyl peroxide into a 100ml beaker Benzenesulfonate, magnetic stirring, the stirring time is 5h, the stirring rate is 1200r / min, and the cross-linked product is obtained at 80°C, and the mass percentage of polyvinyl chloride in the obtained mixed solution is 12%;

[0043] (3) Dip the copper mesh obtained in step (1) into the mixed solution obtained in step (2), keep it for 1 hour, then take it out and dry it in the air at 80°C;

[0044](4) The copper mesh obtained in step (3) is an oil-water separation mesh with superhydrophilic and underwater oleophobic properties in the air, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com