A kind of epoxy resin expansion type fireproof coating for steel structure and preparation method thereof

A technology of epoxy resin and fireproof coating, which is applied in the direction of epoxy resin coating, fireproof coating, coating, etc., to achieve the effects of enhanced fireproof performance, excellent fireproof performance and physical and chemical properties, and high fireproof efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Preparation of modified polyethyleneimine fire protection additive

[0043] Add 100g of polyethyleneimine (PEI) with a molecular weight of 600-70000, 138g of diethyl phosphite and 100ml of dichloromethane into the reaction kettle, and add 185g of carbon tetrachloride and 122g of Triethylamine, after reacting for 24h, was rotary evaporated to obtain the crude product. The product was dissolved in 500 ml of distilled water, dialyzed to remove impurities, and then freeze-dried to obtain the final product modified polyethyleneimine (PEI-DEPP).

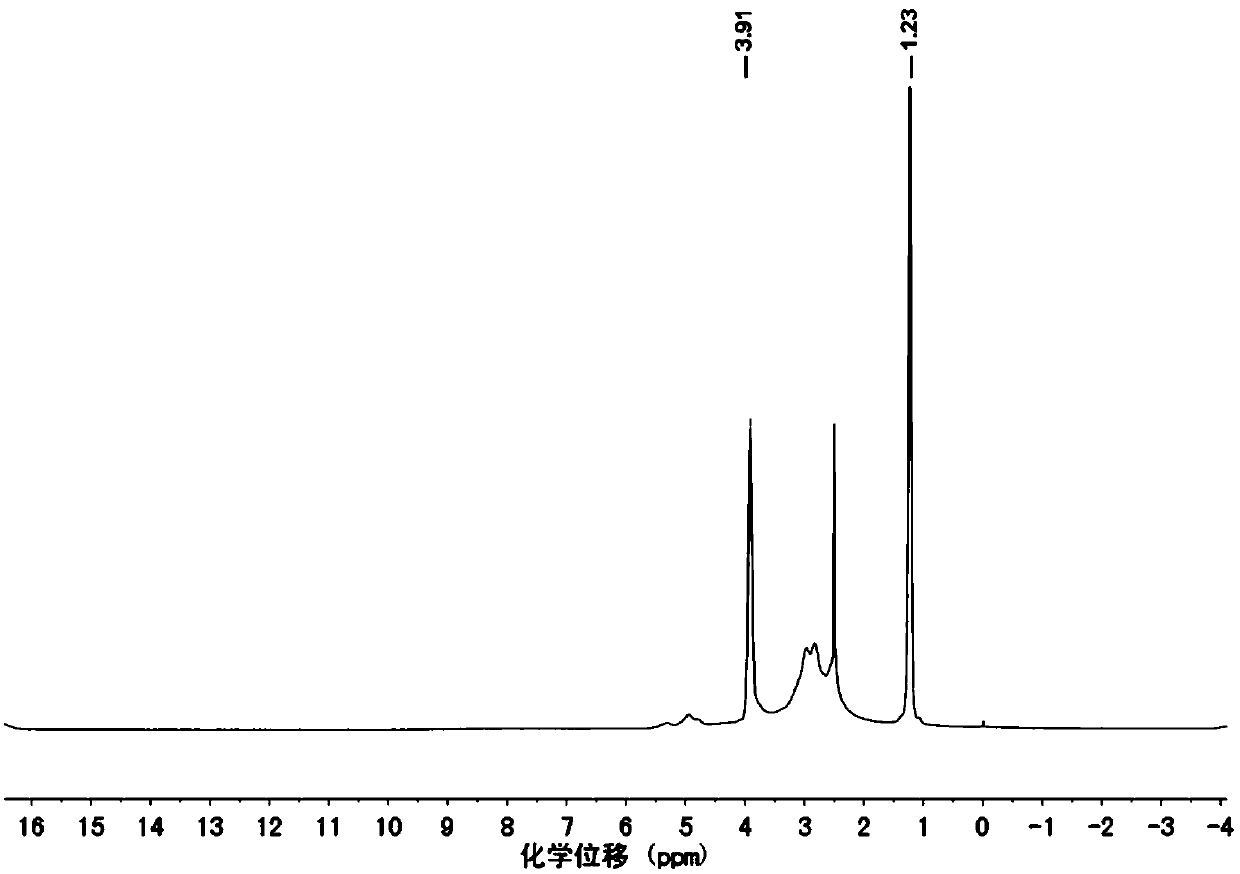

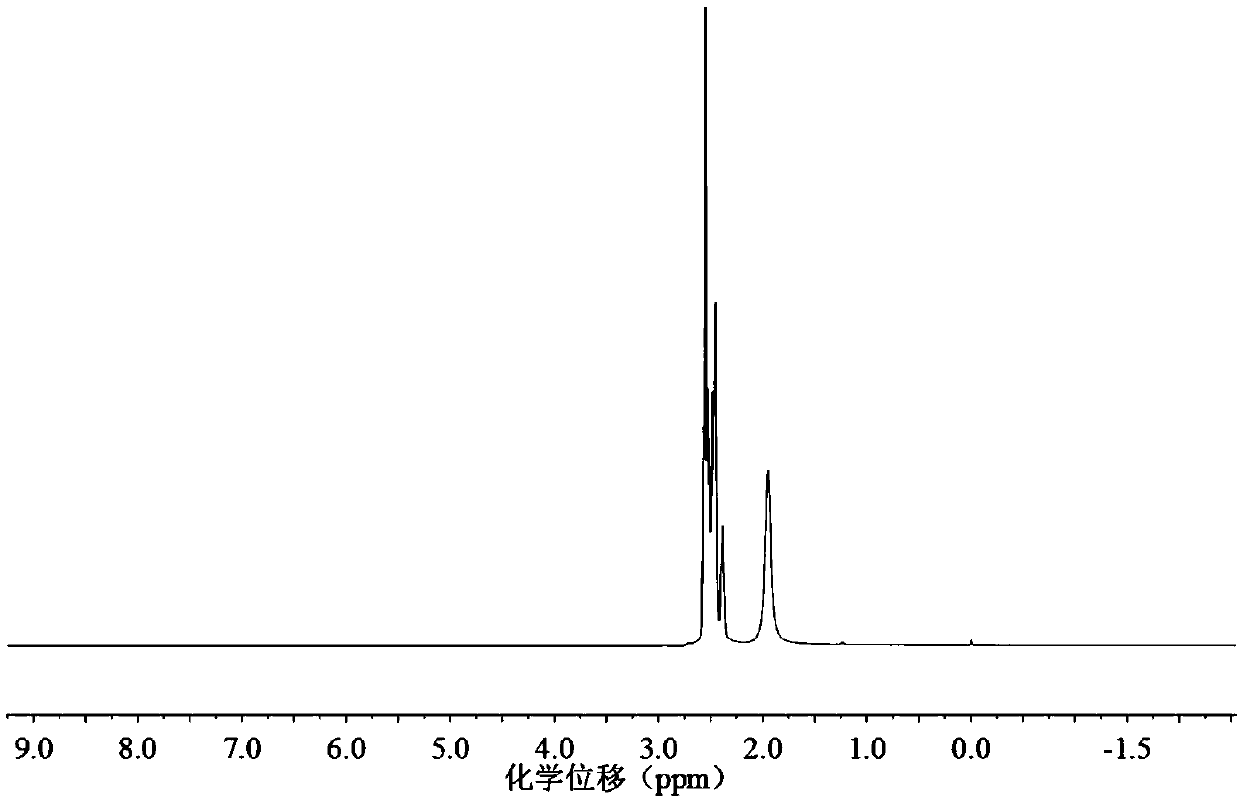

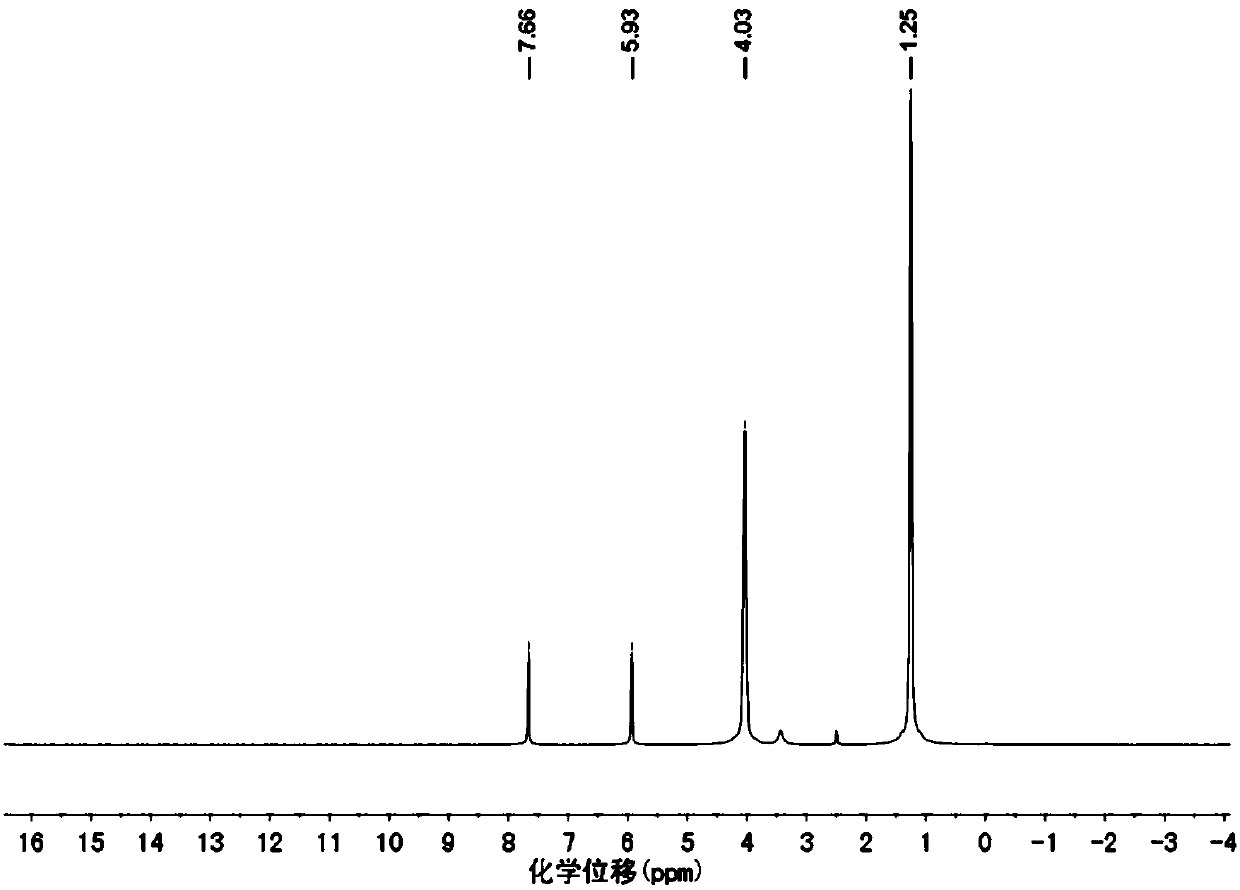

[0044] Depend on figure 1 of 1 HNMR nuclear magnetic spectrum and figure 2 , image 3 By comparison, it can be seen that the amine group proton peak of polyethyleneimine PEI appeared at 2-3ppm, but there was no P-H proton peak of diethyl phosphite at 7.66ppm and 5.93ppm, and there were diethylphosphite at 1.23ppm and 3.91ppm respectively. Methyl and methylene peaks of ethyl esters. Explain the successful synthesis of ...

Embodiment 2

[0053] Step 1: Preparation of modified polyethyleneimine fire protection additive

[0054] Add 100g of polyethyleneimine with a molecular weight of 600-70000, 125g of diethyl phosphite and 100ml of dichloromethane into the reaction kettle, and add 185g of carbon tetrachloride and 122g of triethylamine dropwise within 6 hours under ice bath conditions , After reacting for 24h, the crude product was obtained by rotary evaporation. The product was dissolved in 500 ml of distilled water, dialyzed to remove impurities, and then freeze-dried to obtain the final product modified polyethyleneimine.

[0055] Step 2: Dissolve 450g epoxy resin in the mixed solvent of 120g xylene, 80g n-butanol and 40g butyl acetate, then add dehydration charcoal catalyst that is 340g ammonium polyphosphate and 170g melamine phosphate, blowing agent is 190g melamine And 95g urea, carbon forming agent is 120g pentaerythritol and 60g mannitol, 41g expandable graphite, pigment and filler are 30g titanium di...

Embodiment 3

[0062] Step 1: Preparation of modified polyethyleneimine fire protection additive

[0063] Add 100g of polyethyleneimine with a molecular weight of 600-70000, 138g of diethyl phosphite and 100ml of dichloromethane into the reaction kettle, and add 185g of carbon tetrachloride and 122g of triethylamine dropwise within 6 hours under ice-bath conditions , After reacting for 24h, the crude product was obtained by rotary evaporation. The product was dissolved in 500 ml of distilled water, dialyzed to remove impurities, and then freeze-dried to obtain the final product modified polyethyleneimine.

[0064] Step 2: 600g epoxy resin is dissolved in the solvent that 141g xylene, 94g n-butanol, 47g butyl acetate mix, then add dehydration charcoal catalyst namely 420g ammonium polyphosphate and 210g melamine phosphate, foaming agent is 180g melamine Mix with 90g urea, char-forming agent, 140g pentaerythritol and 70g mannitol, 50g expandable graphite, pigments and fillers namely 45g titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com