Preparation method of flame-retardant and high-performance polyimide aerogel

A kind of polyimide wet gel, polyimide technology, applied in the field of preparation of flame-retardant high-performance polyimide aerogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

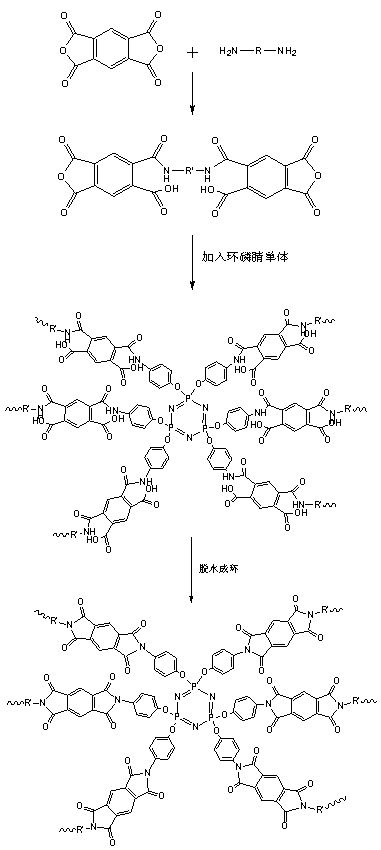

Method used

Image

Examples

Embodiment 1

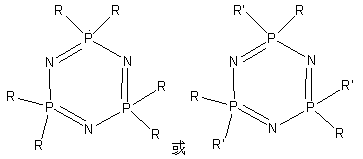

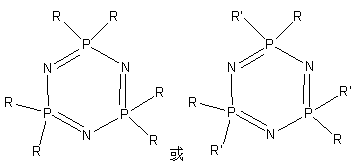

[0026] Dissolve 1.1800 g of 3,3’,4,4’-diphenyl ether tetracarboxylic dianhydride (ODPA) and 0.7490 g of diaminodiphenyl ether (ODA) in 30 mL and 20 mL of NMP solvent, respectively. Heating and stirring can be used to speed up the dissolution. After complete dissolution, the diamine solution is added dropwise to the dianhydride solution, and reacted at room temperature for 8 hours to obtain a polyamic acid solution. Add a solution of 0.0150g of hexaaminocyclotriphosphazene dissolved in 2mL of NMP to the polyamic acid solution, and after stirring for 10 minutes, quickly add 5.7570g of acetic anhydride and 4.9270g of pyridine for dehydration treatment, and quickly stir evenly. After reacting for 6 hours, the solvent was replaced with 100 mL of acetone and 100 mL of cyclohexane, and then left to stand at room temperature for 12 hours. Finally, supercritical CO 2 Drying technology Dry the wet gel at 40°C and 15MPa for 8 hours to finally obtain a cross-linked airgel with low water ...

Embodiment 2

[0028] Dissolve 3.153g of pyromellitic dianhydride (PMDA) into 60ml of NMP, heat to 40°C and stir, then add 2.803g of 4,4'-diaminoanisole (ODA) into 50ml of NMP, After heating and stirring until dissolved, the diamine monomer and the dianhydride monomer were mixed and stirred at room temperature for 10 hours under the protection of nitrogen to obtain a polyamic acid solution. Add 0.112g of hexaaminocyclotriphosphazene dissolved in 5mL of NMP into the polyamic acid solution, stir rapidly, add 15.3g of acetic anhydride and 11.865g of pyridine after 10 minutes, and carry out the dehydration and cyclization reaction for a period of time. Solvent replacement was performed sequentially with 200 mL of acetone and 200 mL of cyclohexane solvent to obtain a polyimide wet gel. Finally, the wet gel was subjected to supercritical CO 2 Drying, 15MPa, 40°C, then vacuum drying at 80°C for 12 hours. The obtained product has a density of 0.28g / cm 3 , specific surface area 298m 2 / g, the gla...

Embodiment 3

[0030] Dissolve 1.820g of biphenyltetracarboxylic dianhydride (BPDA) in 40mL of NMP, and dissolve 1.196g of diaminodiphenyl ether (ODA) in 30mL of NMP until completely dissolved. The solutions were mixed and reacted at room temperature for 12 hours under the protection of nitrogen to obtain a polyamic acid solution. Then 0.0678g of hexa(p-aminophenoxy)cyclotriphosphazene was added to the polyamic acid solution, and after 10 minutes of reaction, 6.79g of acetic anhydride and 5.25g of pyridine were added to the solution to start to generate polyamide rings. Acetone and 140 mL of cyclohexane solvent were used for solvent replacement, and then left to stand at room temperature for 12 h. Finally, supercritical CO was applied to polyimide wet gels. 2 dry. The obtained product has a density of 0.22g / cm 3 , specific surface area 248m 2 / g, the glass transition temperature is 298°C, and the limiting oxygen index is 51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com