An improved processing technology of type 1 slow-release long-lasting super-hydrophobic antifouling flashover coating

An anti-fouling flashover coating and processing technology, applied in the field of coatings, can solve the problems of low elongation, breaking strength and tear strength, easy detachment of coating, poor corrosion resistance, etc., and achieve long-term hydrophobic mobility, Improve hydrophobic migration, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

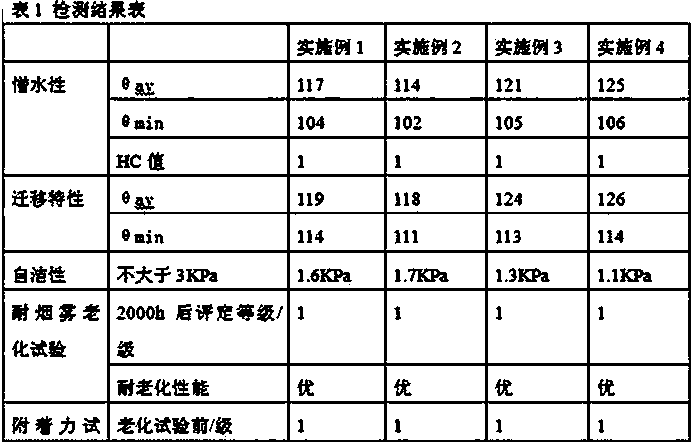

Examples

Embodiment 1

[0050] A kind of processing technology of improved type 1 slow-release long-acting super-hydrophobic anti-fouling flashover coating, comprising the following steps:

[0051] ①Stir 100kg of trifluoropropylmethylcyclotrisiloxane, 25kg of tetramethyldisiloxane and 250kg of dodecamethylcyclohexasiloxane evenly, add 12.5kg of sodium sulfate, stir well and heat up to 60°C , then drop 5kg of concentrated hydrochloric acid with a concentration of 37% therein, react for 1 hour after the dropwise addition, cool to 20°C, add ammonia water, adjust the pH to 6, and obtain hydrogen-terminated fluoropolysiloxane;

[0052] ②Take 80kg of hydrogen-terminated fluoropolysiloxane obtained in step ① and 10kg of methallyl alcohol, stir evenly, add 0.2kg of metal nickel, raise the temperature to 80°C, and react for 1 hour to obtain hydroxypropyl-terminated fluoropolysiloxane Oxygen;

[0053] ③Raise the temperature to 40kg of octamethylcyclotetrasiloxane to 50°C, add 0.1kg of concentrated sulfuric ac...

Embodiment 2

[0058] A kind of processing technology of improved type 1 slow-release long-acting super-hydrophobic anti-fouling flashover coating, comprising the following steps:

[0059] ①Stir 60kg of trifluoropropylmethylcyclotrisiloxane, 10kg of tetramethyldisiloxane and 150kg of dodecamethylcyclohexasiloxane evenly, add 10kg of sodium sulfate, stir evenly and heat up to 70°C, Then, 5 kg of concentrated hydrochloric acid with a concentration of 37% was added dropwise thereto, reacted for 2 hours after the dropwise addition, cooled to 30° C., added ammonia water, and adjusted the pH to 7 to obtain hydrogen-terminated fluoropolysiloxane;

[0060] ②Take 45kg of hydrogen-terminated fluoropolysiloxane and 7.5kg of methallyl alcohol obtained in step ①, stir evenly, add 0.25kg of metal nickel, heat up to 90°C, and react for 2 hours to obtain hydroxypropyl-terminated fluoropolysiloxane Silicone;

[0061] ③Raise the temperature to 42.5kg octamethylcyclotetrasiloxane to 60°C, add 0.25kg concentra...

Embodiment 3

[0066] A kind of processing technology of improved type 1 slow-release long-acting super-hydrophobic anti-fouling flashover coating, comprising the following steps:

[0067] ①Stir 45kg of trifluoropropylmethylcyclotrisiloxane, 10kg of tetramethyldisiloxane and 120kg of dodecamethylcyclohexasiloxane evenly, add 8kg of sodium sulfate, stir evenly and heat up to 62°C, Then, 3 kg of concentrated hydrochloric acid with a concentration of 37% was added dropwise thereto, reacted for 1.5 hours after the dropwise addition, cooled to 22°C, added ammonia water, and adjusted the pH to 6.5 to obtain hydrogen-terminated fluoropolysiloxane;

[0068] ②Take 41kg of hydrogen-terminated fluoropolysiloxane obtained in step ① and 7kg of methallyl alcohol, stir evenly, add 0.15kg of metal nickel, heat up to 84°C, and react for 1.5 hours to obtain hydroxypropyl-terminated fluoropolysiloxane Oxygen;

[0069] ③Raise the temperature to 41kg of octamethylcyclotetrasiloxane to 52°C, add 0.15kg of concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com