Selenium-containing surfactant having pH and redox double-coincidence switch response

A surfactant and solvent technology, used in the field of selenium-containing surfactants, can solve problems such as interfering with the production process, and achieve the effects of low skin irritation, mild synthesis conditions, and excellent antioxidant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Production of Dibenzyl Diselenide

[0034] Take 63.6g of selenium powder (0.4mol) and mix with 520g of water to cool in an ice water bath under the protection of nitrogen; another 66.7g of sodium borohydride (1.6mol) is completely dissolved in ice water and added to the mixed solution of selenium powder and water at room temperature After reacting for 20-50 minutes, add 0.4mol selenium powder and heat to 70 degrees Celsius to react for 20-30 minutes, then add the benzyl bromide dissolved in tetrahydrofuran in advance at 55 degrees Celsius and stir for 20-30 minutes according to the molar ratio of benzyl bromide: selenium 2:1 After 18 hours, the organic phase was extracted with dichloromethane, dehydrated and dried and the solvent was evaporated. The residue was recrystallized with ethyl acetate to obtain yellow crystals of dibenzyl diselenide. The yield of dibenzyl diselenide was 87.6%.

Embodiment 2

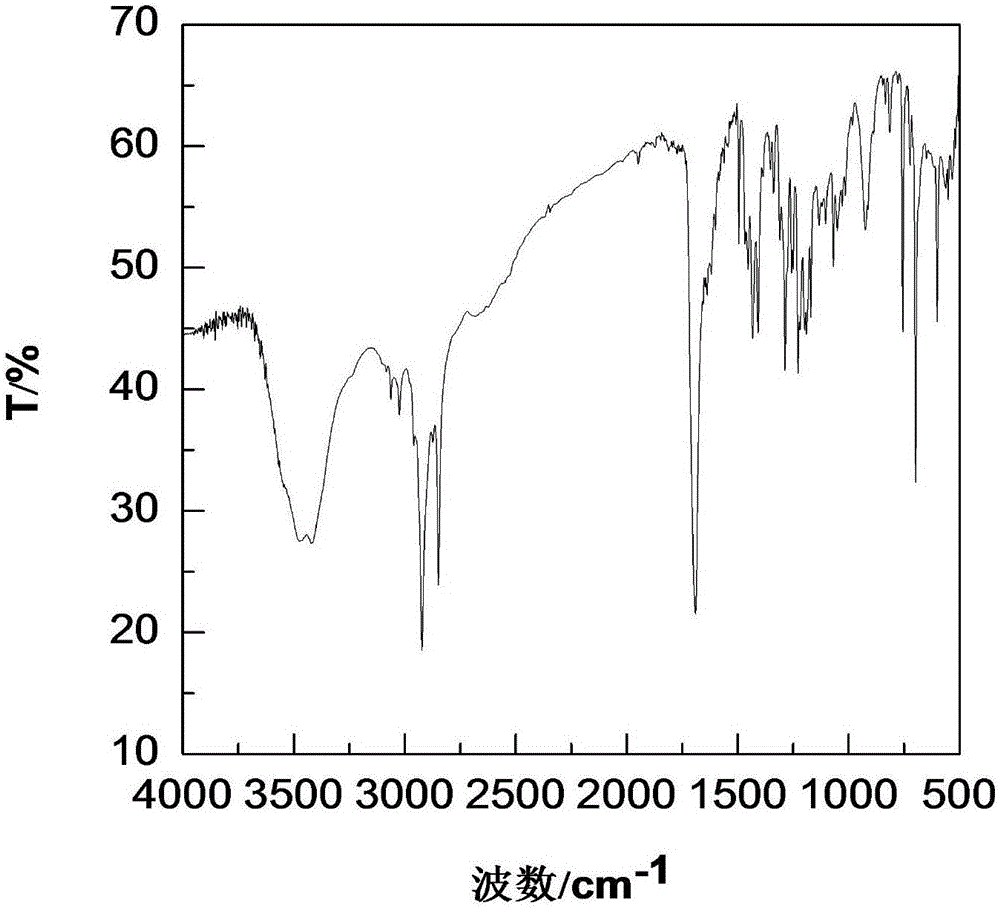

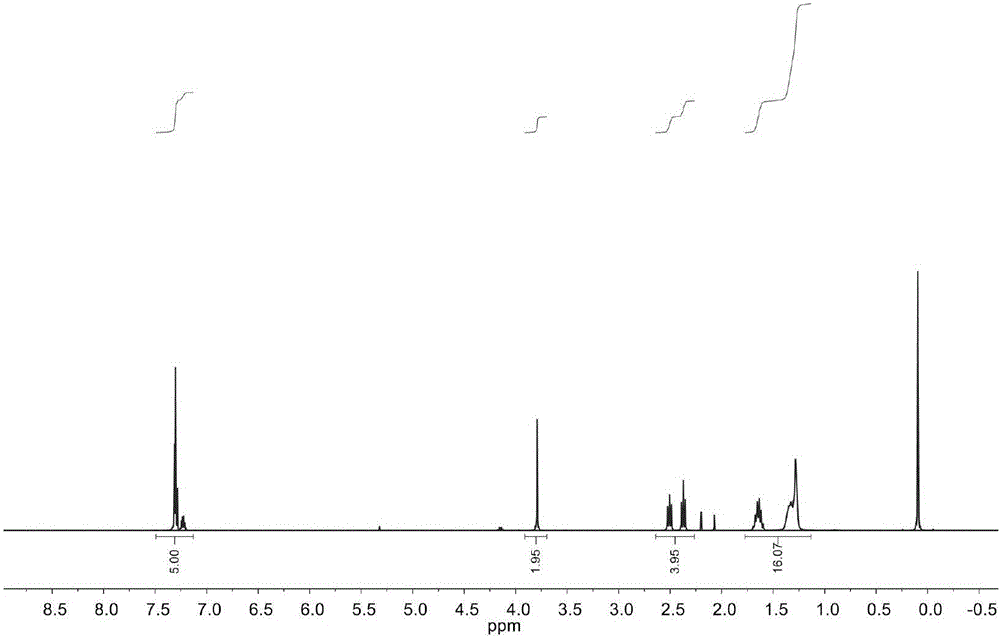

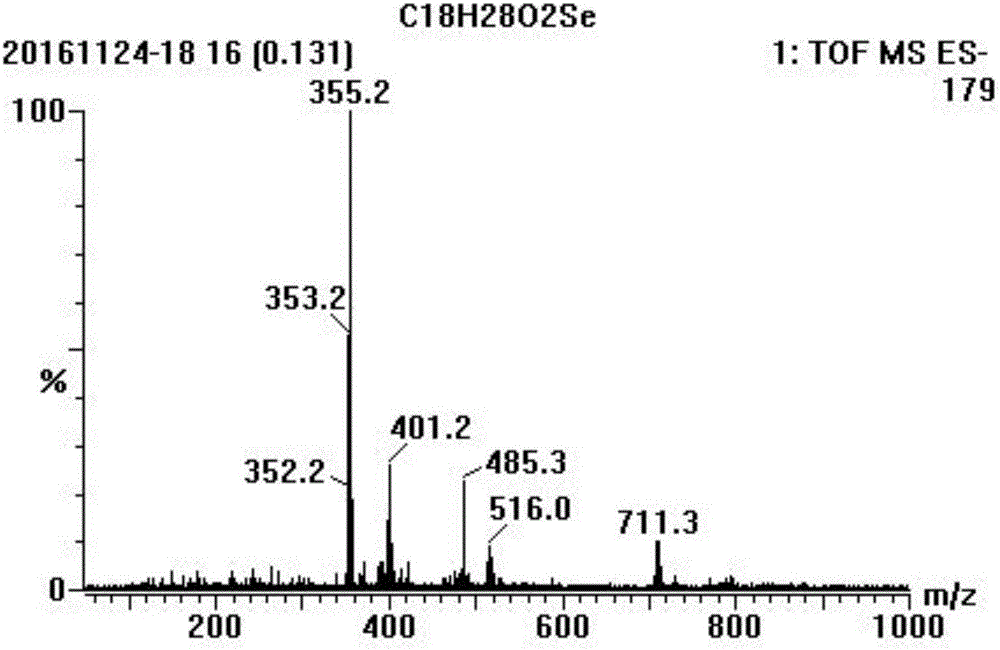

[0035] Example 2: Production of 11-benzylselenoundecanoate

[0036] Under the protection of nitrogen, dissolve 4.08 g of dibenzyl diselenide in 40 mL of tetrahydrofuran, and add dropwise 2.36 g of sodium borohydride dissolved in 50 mL of ice water under ice-water bath conditions. After reaction in the ice-water bath for 2.5 hours, add 30 mL dropwise containing 5.38 g11-Bromo-undecanoic acid in tetrahydrofuran, reacted in an ice-water bath for 0.5 hours, and then evaporate under reduced pressure to remove tetrahydrofuran. The resulting aqueous solution of 11-benzylselenoundecanoate was adjusted to pH 1 with hydrochloric acid and filtered under vacuum 11-benzylselenundecanoic acid crude product, and then the obtained crude 11-benzylselenundecanoic acid product was dissolved in ethyl acetate and washed with deionized water several times to obtain the ethyl acetate of 11-benzylselenundecanoic acid The solution was dried with anhydrous sodium sulfate, and the filtrate obtained by filt...

Embodiment 3

[0039] Example 3: Production of 5-benzylselenovalerate

[0040] Under the protection of nitrogen, dissolve 8.16 g of dibenzyl diselenide in 65 mL of tetrahydrofuran, add dropwise a solution of 7.26 g of sodium borohydride dissolved in 75 mL of ice water under ice-water bath conditions, and after reaction in the ice-water bath for 2.5 hours, add 50 mL dropwise containing 1.73 g 5-bromo-pentanoic acid in tetrahydrofuran, reacted in an ice-water bath for 0.5 hours, and then steamed to remove tetrahydrofuran. The resulting aqueous solution of 5-benzylselenovalerate was adjusted to pH 1 with hydrochloric acid, and filtered under reduced pressure to obtain 5- The crude product of benzylselenovaleric acid, then the obtained crude product of 5-benzylselenovaleric acid was dissolved in ethyl acetate and washed with deionized water three times, and the ethyl acetate solution of the obtained 5-benzylselenovaleric acid was used anhydrous sulfuric acid After drying with sodium, the filtrate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com