Fluorescent film sensor for fluoride ion detection and preparation method of fluorescent film sensor

A thin-film sensor and fluorine ion technology, applied in fluorescence/phosphorescence, instruments, measuring devices, etc., can solve problems such as hindering the rapid diffusion of metal ions to be measured, weakening of the quantum efficiency of thin-film fluorescence, and dissolution, so as to achieve stable adhesion to the substrate Controllable intensity, ensuring permeability and fluorescence efficiency, ensuring rapid diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

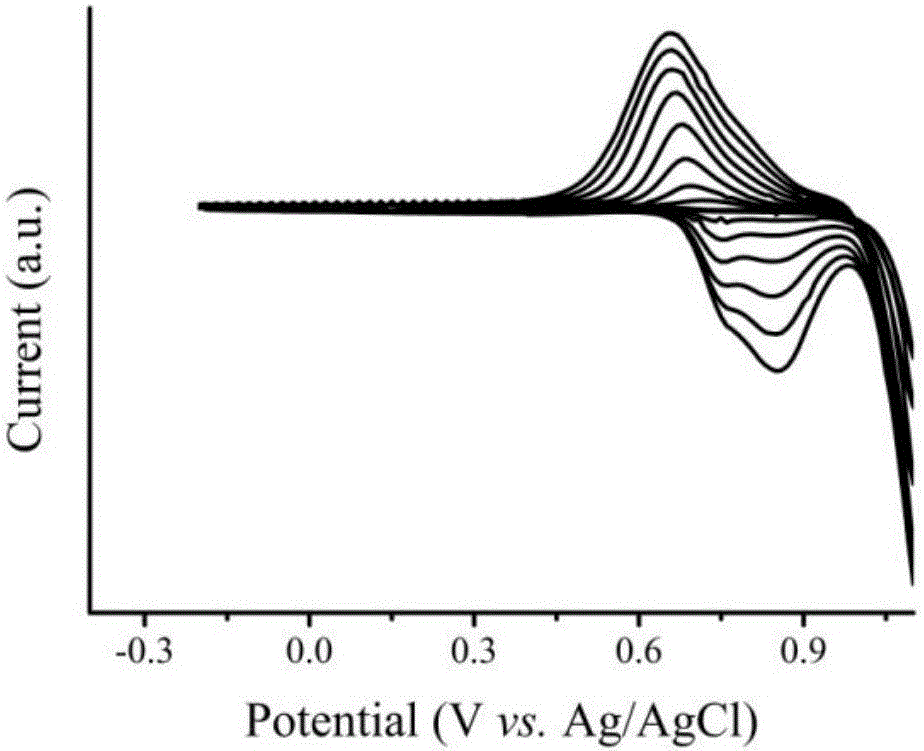

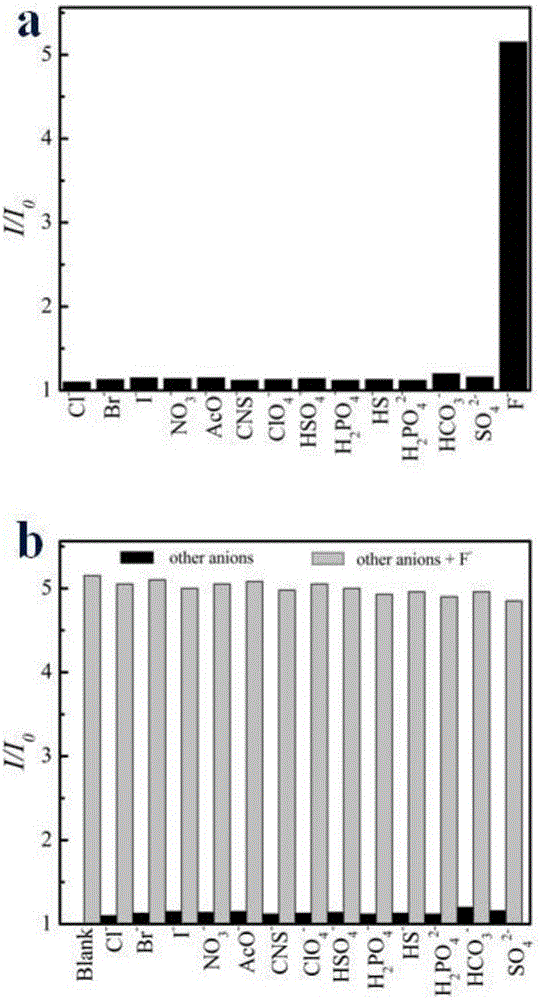

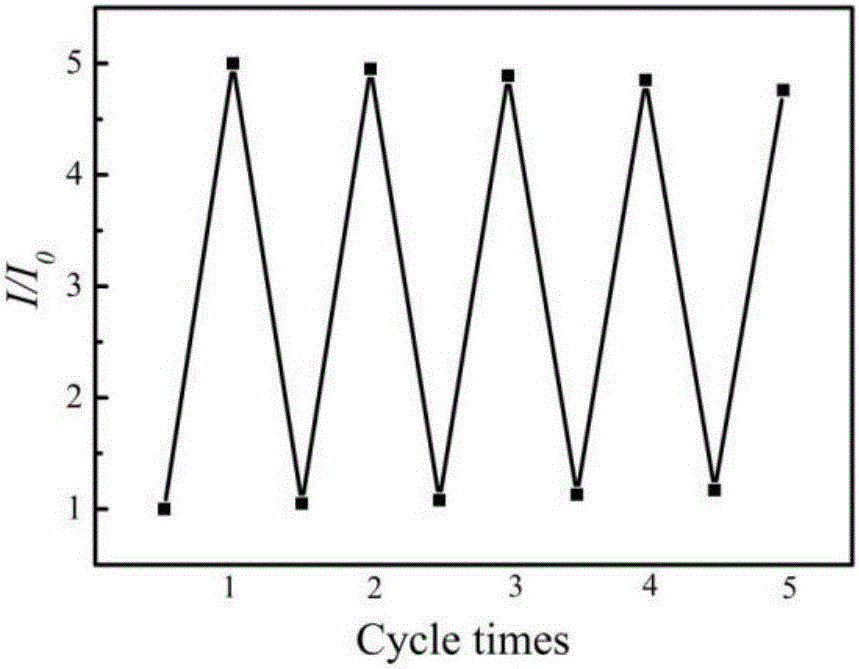

Method used

Image

Examples

Embodiment 1

[0028] (1) Using 3.78g of 2-bromo-9,9-(N-carbazole-hexyl)fluorene as raw material, add solvent triethylamine 20mL, and carry out catalytic reaction with 0.69g trimethylacetylene, the catalyst used includes bis Triphenylphosphine palladium dichloride 20mg, cuprous iodide 20mg and triphenylphosphine 70mg. In the catalytic reaction, the temperature is controlled at 90°C, and the reaction is kept stirring for 5 hours. The crude product obtained by volatilizing the solvent is separated and purified by using petroleum ether / dichloromethane mixed solution (volume ratio: 3:1) to obtain 2-trimethylacetylene Base-9,9-(N-carbazole-hexyl)fluorene. Dissolve 2-trimethylethynyl-9,9-(N-carbazol-hexyl)fluorene in 20 mL THF / H 2 O (volume ratio is 1:1), add 1.12g K 2 CO 3 , The reaction was stirred at room temperature for 2h. The solvent was then removed under reduced pressure, and CH 2 Cl 2 Extraction, the organic layer was washed repeatedly with deionized water and concentrated hydrochlo...

Embodiment 2

[0035](1) Using 2.53g of 2-bromo-9,9-(N-carbazole-hexyl)fluorene as raw material, add 12mL of solvent triethylamine, and carry out catalytic reaction with 0.46g of trimethylacetylene, the catalyst used includes bis Triphenylphosphine palladium dichloride 15mg, cuprous iodide 15mg and triphenylphosphine 56mg. In the catalytic reaction, the temperature is controlled at 80°C, the reaction is kept stirring for 4 hours, and the crude product obtained by volatilizing the solvent is separated and purified by using petroleum ether / dichloromethane mixed solution (volume ratio: 3:1) to obtain 2-trimethylacetylene Base-9,9-(N-carbazole-hexyl)fluorene. Dissolve 2-trimethylethynyl-9,9-(N-carbazol-hexyl)fluorene in 15 mL THF / H 2 O (volume ratio is 1:1), add 0.88g K 2 CO 3 , Stir the reaction at room temperature for 1.5h. The solvent was then removed under reduced pressure, and CH 2 Cl 2 Extraction, the organic layer was washed repeatedly with deionized water and concentrated hydrochlo...

Embodiment 3

[0042] (1) Using 1.62g of 2-bromo-9,9-(N-carbazole-hexyl)fluorene as raw material, add solvent triethylamine 8mL, and carry out catalytic reaction with 0.22g trimethylacetylene, the catalyst used includes bis Triphenylphosphine palladium dichloride 12mg, cuprous iodide 12mg and triphenylphosphine 38mg. In the catalytic reaction, the temperature is controlled at 80°C, the reaction is kept stirring for 4 hours, and the crude product obtained by volatilizing the solvent is separated and purified by using petroleum ether / dichloromethane mixed solution (volume ratio: 3:1) to obtain 2-trimethylacetylene Base-9,9-(N-carbazole-hexyl)fluorene. Dissolve 2-trimethylethynyl-9,9-(N-carbazol-hexyl)fluorene in 8 mL THF / H 2 O (volume ratio is 1:1), add 0.59g K 2 CO 3 , The reaction was stirred at room temperature for 1 h. The solvent was then removed under reduced pressure, and CH 2 Cl 2 Extraction, the organic layer was washed repeatedly with deionized water and concentrated hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com