Electrochromic sensor array and manufacturing method and application method thereof

A sensor array and electrochromic technology, applied in the field of electrochemical detection and analysis, can solve the problems of increasing the complexity and cost of detection, affecting the portability of paper chips, and low sensitivity of colorimetry, achieving simple and fast detection process and fast detection. , prepare a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

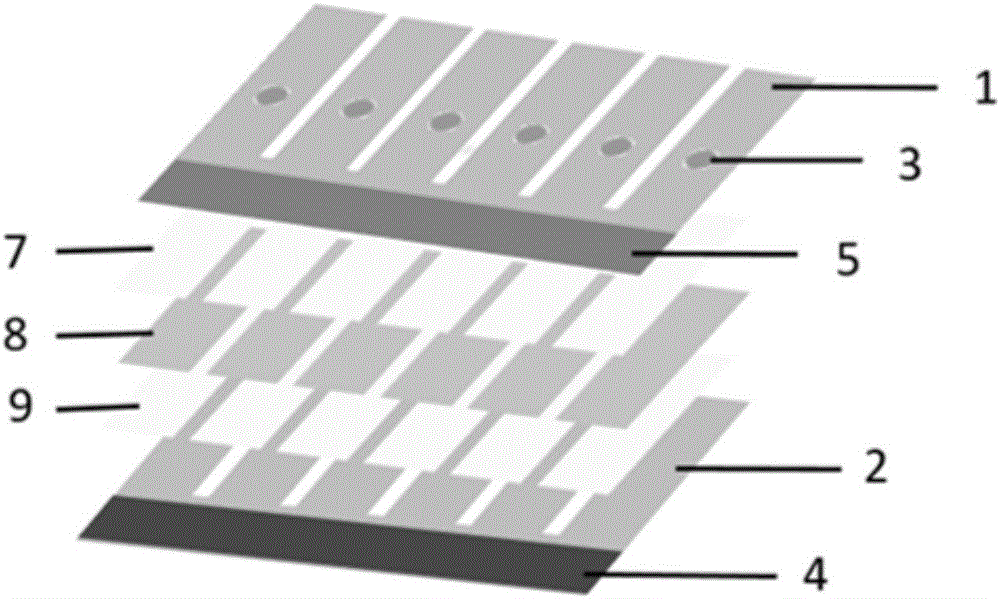

[0036] Embodiment 1 Electrochromic sensor array based on naked eye detection

[0037] An electrochromic sensor array based on naked-eye detection consists of six sensors, and each sensor consists of two parts: a battery part and a sensing part.

[0038] Such as figure 1 As shown, the sensing part includes an ITO electrode and a sample reaction cell. The ITO electrode includes a working electrode 1 and a reference electrode 2, both of which are made of ITO thin film material, wherein the working electrode is decorated with Prussian blue dots 3 as indicators. The diameter of the Prussian blue dot 3 is 1.12 mm, which is modified on the surface of the working electrode 1 by electrodeposition. The deposition solution used in the deposition method is a 60 μL solution with a pH of 2.0. The solution contains 10 mM ferric chloride, 10 mM potassium ferricyanide and 2.6 mM hydrochloric acid. The sample reaction cell includes a cathode reaction area 7 and an anode reaction area 9, and ...

Embodiment 2

[0041] Example 2 Preparation of Electrochromic Sensor Array Based on Naked Eye Detection

[0042]The preparation process of the electrochromic sensor array based on naked-eye detection provided by the present invention includes the following steps:

[0043] a) Cut out two rectangular ITO films with a laser cutting machine as figure 1 The corresponding shape in the sensor array is used as the substrate of the sensor array, that is, the ITO film is cut along the direction parallel to the first side of the rectangular ITO film, so that the second side perpendicular to the first side is separated from each other to form 6 strips. a shape part, the third side parallel to the second side is connected to each other, thereby forming a comb structure;

[0044] Take a cut ITO film, use the comb part as the reference electrode 2, coat the comb handle part connected to each other at one end of the comb part with 2mm×15mm rectangular ink and dry it in the shade to form the positive electr...

Embodiment 3

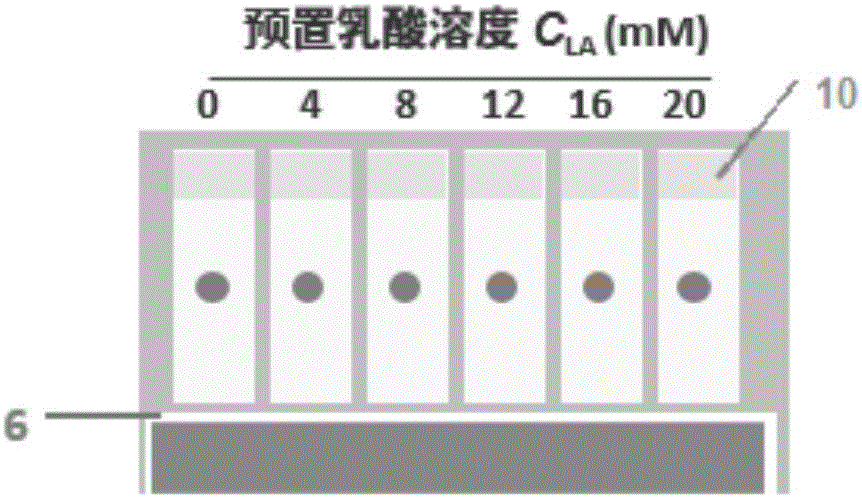

[0064] Embodiment 3 Detection of lactic acid based on an electrochromic sensor array detected by the naked eye:

[0065] The electrochromic sensor array based on naked-eye detection in embodiment 1 is used to detect lactic acid, comprising the following steps:

[0066] 1) Configure a saturated sodium chloride solution, suck the solution into the paper 6 of the battery part, and make the aluminum-oxygen battery conduct.

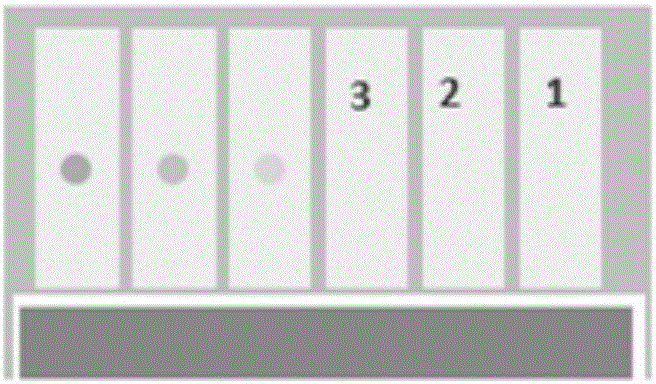

[0067] 2) The negative electrode of the aluminum-oxygen battery is aluminum foil, the positive electrode is carbon ink material, and the paper is used as the electrolytic cell in the middle. When the electrolyte is sucked into the paper, the battery is turned on, and the aluminum-oxygen reaction occurs, generating a voltage of about 1V for chip sensing React uses. The working principle of the sensing part is that when the lactic acid solution is inhaled, the lactic acid reduces potassium ferricyanide to potassium ferrocyanide under the action of lactate oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com