Germanium selenide polycrystal thin film and solar battery comprising thin film, and preparation methods therefor

A technology of solar cells and germanium selenide, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low content, toxic production process for human body, and complexity, and achieve short reaction cycle, excellent photovoltaic performance, and film-forming quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

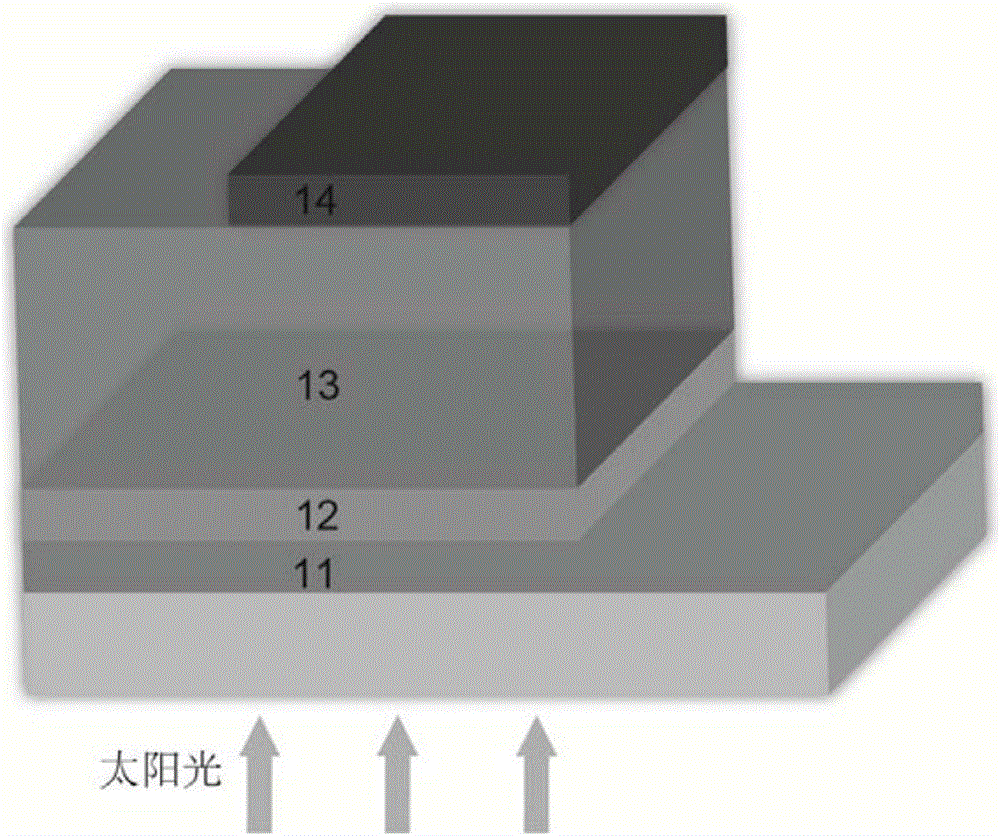

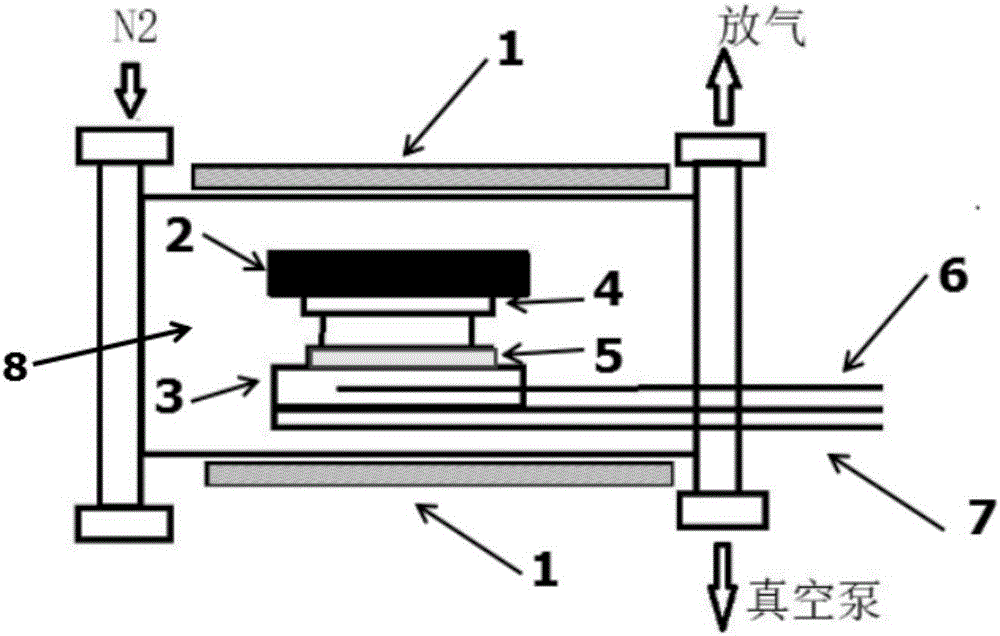

[0060] A method for preparing a thin-film solar cell using a high-quality germanium selenide polycrystalline thin film as an absorbing layer, the specific steps comprising an n-type window layer deposition step, a p-type absorber layer deposition step and a back electrode layer deposition step:

[0061] a) n-type window layer deposition step: using a chemical bath deposition method to deposit an n-type window layer 12 on the conductive glass substrate 11;

[0062] The substrate 11 comprises transparent glass (or white glass) and transparent ITO (In 2 o 3 :Sn) coating (recorded as ITO conductive glass or ITO glass), the thickness is 1.1mm;

[0063] The substrate 11 (commercially available, coating thickness 220-230 angstroms, substrate (transparent glass) sheet resistance<7ohm / sq, light transmittance≥77%) was ultrasonically cleaned with deionized water, acetone and ethanol respectively 30 minutes, then blown with high-purity nitrogen, and then cleaned with UV-ozone for 15 min...

Embodiment 2

[0076] A kind of high-quality germanium selenide polycrystalline thin film is the preparation method of the thin-film solar cell of absorption layer, and concrete preparation method is basically the same as that in embodiment 1, and difference is:

[0077] In step b), the deposition program of the rapid annealing furnace is: C1:20, T1:30, C2:300, T2:1200, C3:300, T3:10, C4:400, T4:5, C5:400, T5:-121 (wherein, the unit of C is ℃, and the unit of T is second), then the germanium selenide polycrystalline thin film under different preheating temperatures can be obtained.

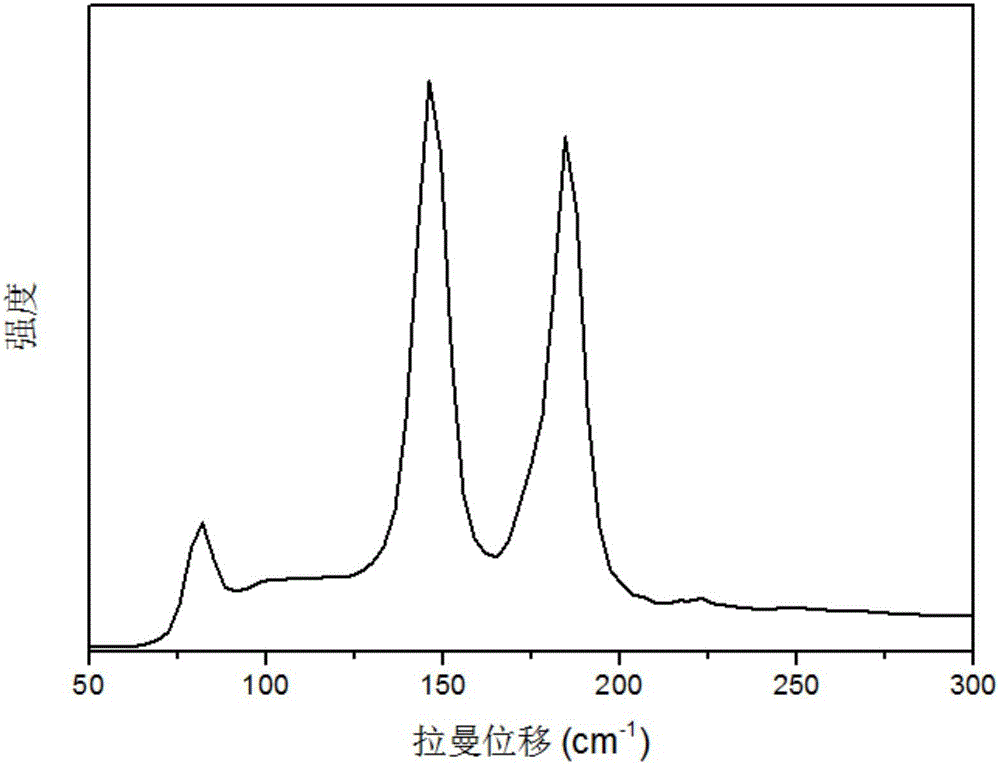

[0078] Figure 7 It is the X-ray powder diffraction pattern of the germanium selenide polycrystalline thin film prepared in Example 2 of the present invention on the ITO glass substrate.

[0079] Figure 8 It is a scanning electron microscope image of the polycrystalline germanium selenide thin film on an ITO glass substrate in Example 2 of the present invention.

[0080] The germanium selenide polycrystallin...

Embodiment 3

[0082] A kind of high-quality germanium selenide polycrystalline thin film is the preparation method of the thin-film solar cell of absorption layer, and concrete preparation method is basically the same as that in embodiment 1, and difference is:

[0083] In step b), the deposition program of the rapid annealing furnace is: C1:20, T1:30, C2:350, T2:1200, C3:350, T3:10, C4:450, T4:5, C5:450, T5:-121 (wherein, the unit of C is ℃, and the unit of T is second), and germanium selenide polycrystalline thin films at different sublimation temperatures can be obtained.

[0084] Figure 10 It is the X-ray powder diffraction spectrum of the germanium selenide polycrystalline thin film prepared in Example 3 of the present invention on an ITO glass substrate.

[0085] Figure 11 It is a scanning electron microscope image of the polycrystalline germanium selenide thin film on an ITO glass substrate in Example 3 of the present invention.

[0086] Through the germanium selenide polycrysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com