Dentin desensitization material resistant to acid, abrasion and caries and preparation method thereof

A dentin and desensitization technology, applied in the field of biomedical engineering, can solve problems such as unreported research, achieve the effect of process parameter control, simple preparation process, and caries prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) At room temperature, weigh 0.944 g of calcium nitrate tetrahydrate and 0.3168 g of diammonium hydrogen phosphate into a beaker filled with 60 mL of double-distilled water, respectively, and dissolve them in a beaker filled with 60 mL of double-distilled water. Sonicate for 5 minutes at a power of 400 W. Place on a magnetic stirrer and stir for 15 minutes to obtain liquid I and liquid II respectively;

[0038] (2) Weigh 0.24 g of dry mesoporous silicon powder into a beaker filled with 20 mL of double-distilled water, and disperse ultrasonically for 5 minutes at a power of 400 W to obtain liquid III, which is then placed on a magnetic stirrer at a stirring speed of Slowly add liquid I to liquid III dropwise at 200 rpm, adjust and keep the pH value between 10-10.5, stir for 12 hours to obtain liquid IV;

[0039] (3) Slowly add liquid II to liquid IV dropwise at a stirring speed of 200 rpm, adjust and maintain the pH value between 10-10.5, and stir for 30 hours to obtai...

Embodiment 2

[0046] (1) At room temperature, weigh 1.888g of calcium nitrate tetrahydrate and 0.6336g of diammonium hydrogen phosphate into a beaker filled with 60 mL of double-distilled water, respectively, and dissolve them in a beaker filled with 60 mL of double-distilled water. Sonicate for 5 minutes at a power of 400 W. Stir on a magnetic stirrer at 400 rpm for 15 minutes to obtain liquid I and liquid II respectively;

[0047] (2) Weigh 0.48 g of dry mesoporous silicon powder into a beaker filled with 20 mL of double-distilled water, and disperse ultrasonically for 5 minutes at a power of 400 W to obtain liquid III, which is then placed on a magnetic stirrer at a stirring speed of Slowly add liquid I to liquid III dropwise at 300 rpm, adjust and maintain the pH value between 10-10.5, stir for 12 hours to obtain liquid IV;

[0048] (3) Slowly add liquid II to liquid IV dropwise at a stirring speed of 300 rpm, adjust and maintain the pH value between 10-10.5, and stir for 30 hours to ob...

Embodiment 3

[0055] (1) At room temperature, weigh 3.776g of calcium nitrate tetrahydrate and 1.2672g of diammonium hydrogen phosphate into a beaker filled with 60 mL of double-distilled water, respectively, and dissolve them in a beaker filled with 60 mL of double-distilled water. Put it on a magnetic stirrer and stir for 15 minutes to obtain liquid I and liquid II respectively;

[0056] (2) Weigh 0.96 g of dry mesoporous silicon powder into a beaker filled with 40 mL of double-distilled water, and ultrasonically disperse at a power of 400 W for 5 minutes to obtain liquid III, which is then placed on a magnetic stirrer at a stirring speed of Slowly add liquid I to liquid III dropwise at 400 rpm, adjust and maintain the pH value between 10-10.5, stir for 12 hours to obtain liquid IV;

[0057] (3) Slowly add liquid II to liquid IV dropwise at a stirring speed of 400 rpm, adjust and maintain the pH value between 10-10.5, and stir for 30 hours to obtain liquid V;

[0058] (4) After aging for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

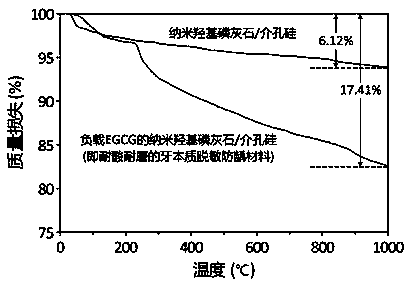

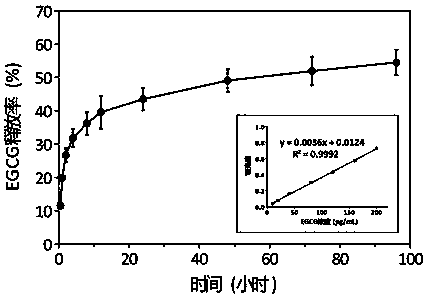

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com