Method for preparing porous flaky nano aluminum oxide

A nano-alumina and flake technology, applied in the field of preparation of porous flake nano-alumina, can solve the problems of complex process, high energy consumption of molten salt method, difficult control of crystal phase, etc. , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

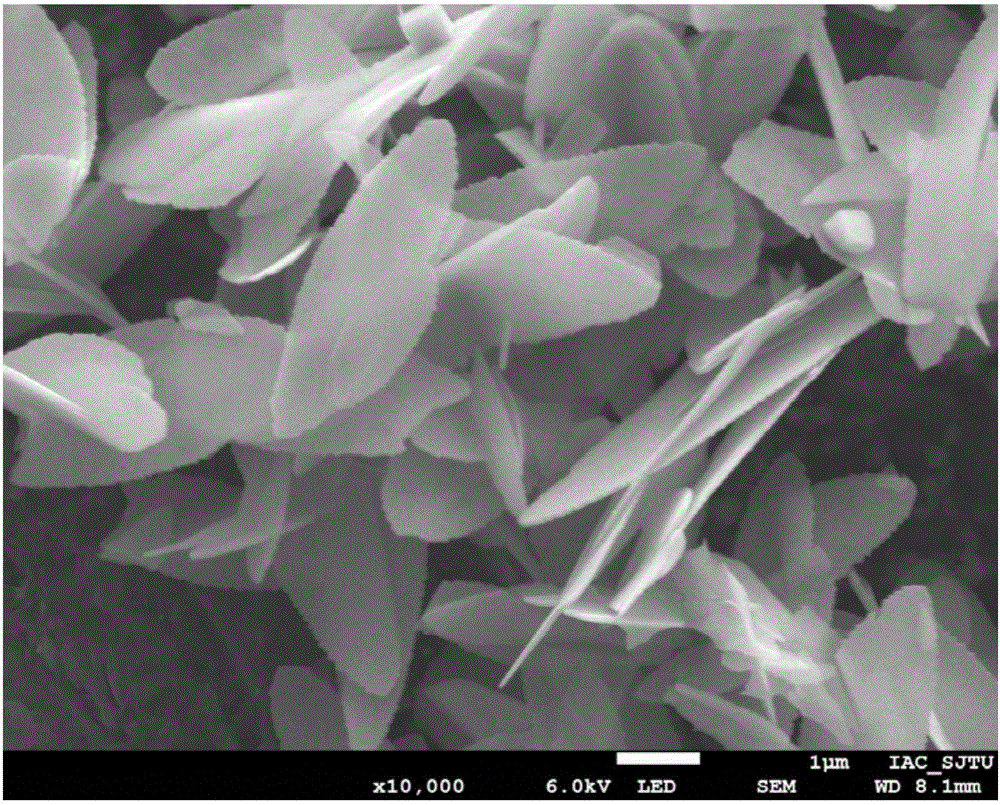

[0030] Weigh 1 gram of sodium nitrate and 11.25 grams of tetrapropylammonium hydroxide, add them to 50 ml of deionized water, stir well until they are completely dissolved to form a transparent solution, then add 3 grams of aluminum isopropoxide to the above solution, at room temperature Stir and hydrolyze for 24 hours, then heat at 80°C for 24 hours and 150°C for 72 hours under dynamic conditions of 120 rpm, cool to room temperature, filter, wash, dry at 110°C, and roast at 550°C to obtain the following: figure 1 The sheet-like nano-alumina shown has a thickness of 20-30nm, a length of 2-3μm, an average pore diameter of 18.8nm, and a specific surface area of 165m 2 / g.

Embodiment 2

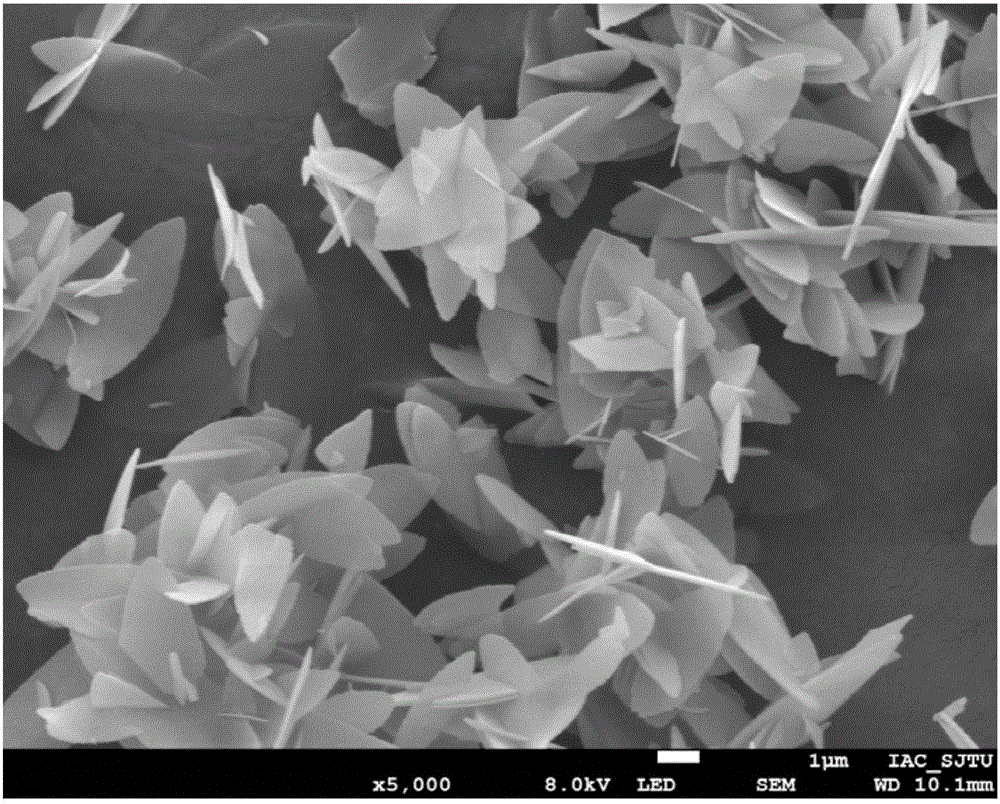

[0032] Weigh 0.62 grams of sodium chloride and 11.25 grams of tetrabutylammonium hydroxide, add them to 50 milliliters of deionized water, stir well until completely dissolved to form a transparent solution, then add 3 grams of aluminum isopropoxide to the above solution, and stir at room temperature Hydrolyze for 24 hours, then heat at 80°C for 24 hours and 150°C for 72 hours under the dynamic condition of 120 rpm, cool to room temperature, filter, wash, dry at 110°C, and roast at 550°C to obtain the following: figure 2 The sheet-like nano-alumina shown has a thickness of 10-20nm, a length of 1.5-2.5μm, an average pore diameter of 17.3nm, and a specific surface area of 175m 2 / g.

Embodiment 3

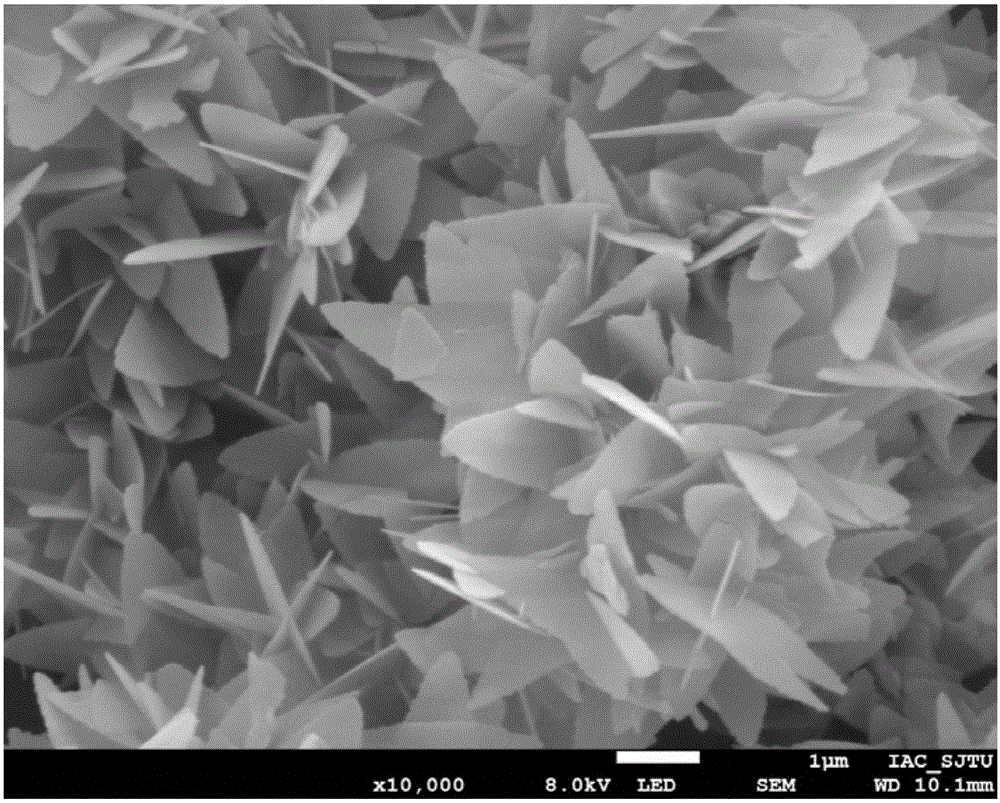

[0034]Weigh 0.62 g of sodium chloride, 11.25 g of tetrapropylammonium hydroxide and 2.5 g of polyethylene glycol 20000, add them to 50 ml of deionized water, stir well until completely dissolved to form a transparent solution, and then add 3 g of isopropanol Aluminum was added to the above solution, stirred and hydrolyzed at room temperature for 24 hours, then heated at 80°C for 24 hours and at 150°C for 72 hours under dynamic conditions of 120 rpm, cooled to room temperature, filtered, washed, and dried at 110°C , after calcination at 550℃ image 3 The sheet-like nano-alumina shown has a thickness of 15-25nm, a length of 1.0-2.5μm, an average pore diameter of 20.5nm, and a specific surface area of 255m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com