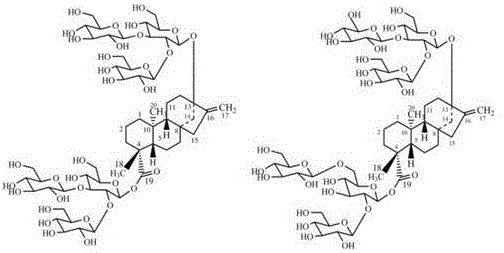

Method for preparing rebaudioside M2 by catalyzing rebaudioside A through recombinant bacterium

A technology of recombinant bacteria and recombinant plasmids, which is applied in the field of genetic engineering, can solve the problems of low content of rebaudioside M2, high cost of enzyme production, and high cost, and achieve better environmental friendliness, simplify the process, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Construction of recombinant strains

[0028] The gene sequence of tomato-derived glycosyltransferase UGTSL2 is shown in SEQ.NO.1, and the gene sequence of potato-derived sucrose synthase StSUS1 is shown in SEQ.NO.2 and synthesized by Nanjing GenScript after codon optimization. Primers GGGAATTCCATATGGCGACCAACCTGCG and CCGCTCGAGTTAGTGGTGATGATGGTGATGTTTG were designed to amplify the UGTSL2 gene, and the gene was subcloned into pRSFDuet-1 (Novagen) between the NdeI and XhoI sites to construct a recombinant plasmid pRSFDuet-SL2; primers were designed for TAATAAGGAGATATACCATGGCCGAACGTGTCCTGACCC and AGGCGCGTCGAGCTCGA The one-step cloning kit (One Step Cloning Kit, Vazyme) of Science and Technology Co., Ltd. subcloned the StSUS1 gene into the NcoI and EcoRI sites of pRSFDuet-SL2 to construct the recombinant plasmid pRSFDuet-SL2-SUS1. In the molecular cloning operation, TransFastTaq DNA polymerase was purchased from Beijing Quanshijin Biotechnology Co., Ltd., and T4 DN...

Embodiment 2

[0029] Example 2 Induced expression of recombinant enzyme and preparation of crude enzyme solution

[0030] The pRSFDuet-SL2-SUS1 constructed in Example 1 was transformed into Escherichia coli BL21 (DE3) to obtain recombinant BL21 (pRSFDuet-SL2-SUS1). Inoculate the recombinant bacterial strain into 5mL LB medium (0.5g / L yeast powder, 0.5g / L sodium chloride, 1g / L tryptone) containing 0.05g / L kanamycin, shake at 37°C and 250rpm Cultivate for 8 hours, then insert the culture solution into 100mL induction medium (25g / L yeast powder, 15g / L tryptone, 10g / L sodium chloride, 2g / L glucose, 0.05g / L lactose ) in a 500mL shake flask, cultured at 200rpm, 30℃ for 2h, until OD 600 When it reaches about 0.2, turn to 25°C to induce 22h and centrifuge to collect the bacteria. Sonicate the bacteria, centrifuge and take the supernatant as a crude enzyme solution, and store it in a 4°C refrigerator for later use.

Embodiment 3

[0031] Example 3 Effects of Temperature on Induced Expression of Recombinant Strains

[0032] Inoculate the recombinant bacteria into 5mL LB medium (0.5g / L yeast powder, 0.5g / L sodium chloride, 1g / L tryptone) containing 0.05g / L kanamycin, and culture with shaking at 250rpm at 37°C 8h, then add the culture solution into 100mL induction medium (25g / L yeast powder, 15g / L tryptone, 10g / L sodium chloride, 2g / L glucose, 0.05g / L lactose) according to the inoculum amount of 2% In a 500mL shake flask, cultured at 200rpm at 30°C for 2h, until the OD 600 When it reaches about 0.2, induce 22 hours of centrifugation at 20°C, 25°C, 30°C, and 37°C to collect the bacteria, ultrasonically destroy the bacteria, and centrifuge to get the supernatant as a crude enzyme solution, and put it in a 4°C refrigerator for use.

[0033] Take the crude enzyme solution obtained at different induction temperatures, react for 25 hours under the conditions of temperature 30°C, pH 7.2, rebaudioside A 10g / L, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com