Aptamer sensor for detecting bisphenol A and preparation method of aptamer sensor

An aptamer sensor and aptamer technology, applied in the field of electrochemical biosensors, can solve the problems of not being reached, and achieve the effects of low detection limit, good recovery rate, and strong specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

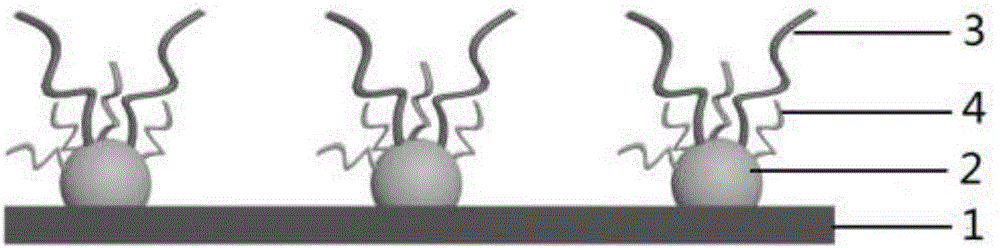

[0028] Example 1: Preparation of an aptasensor for detecting bisphenol A (1)

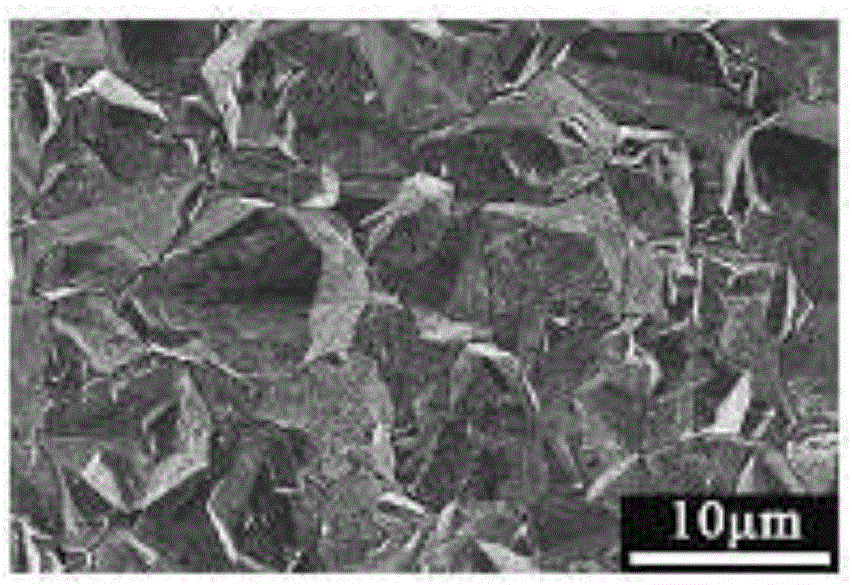

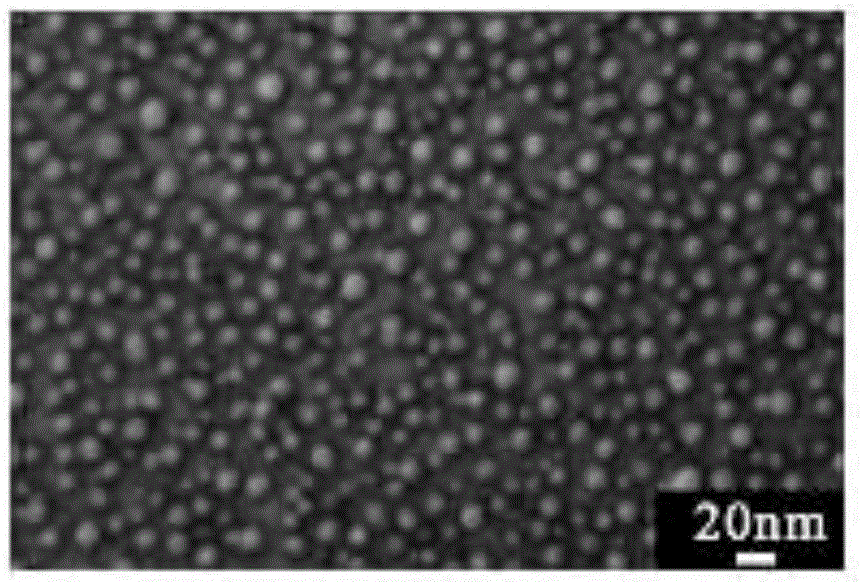

[0029] Conductive diamond films (boron doped) were deposited on silicon substrates by microwave plasma chemical vapor deposition equipment. Ion sputtering gold target 6 seconds on diamond surface then, obtain gold film / boron-doped diamond film structure (see figure 2 ), the sample was transferred to a high-temperature tube furnace, annealed at a high temperature for 1 minute, and washed with deionized water to obtain a gold nanoparticle / diamond film structure (see image 3 ). Add 2 μmol / L aptamer dropwise to the surface of gold nanoparticles / boron-doped diamond film, seal it overnight at 37-39 °C, and rinse it with buffer solution; then immerse the obtained electrode in 1 mmol / L mercaptohexanol (6 -Mercaptohexan-1-ol (MCH)) solution was modified for 2 hours to obtain an aptamer sensor for detecting bisphenol A.

[0030]The aptamer is an oligonucleotide sequence or a short polypeptide screened fr...

Embodiment 2

[0032] Example 2: Preparation of an aptasensor for detecting bisphenol A (2)

[0033] The boron-doped conductive diamond film is deposited on the silicon substrate by microwave plasma chemical vapor deposition or / and hot wire chemical vapor deposition. Then sputtering a layer of gold film on the surface of the conductive diamond by means of electron sputtering or magnetron sputtering for 5-8 seconds and with a thickness of 10-30nm. The resulting gold film / diamond film is annealed at 800-850° C. for 1-2 minutes in a high-temperature tube furnace, and cleaned with deionized water to obtain a gold nanoparticle / diamond film structure (see image 3 ). In an airtight container, disperse 2-2.5 μmol / L of mercapto-modified aptamers on the surface of dry gold nanoparticles / diamonds, assemble overnight at 37-39 ° C, soak and wash in deionized water for 2-3 hours, and obtain Bisphenol A aptasensor.

[0034] The thiol-modified aptamer in this example can be selected from the product syn...

Embodiment 3

[0035] Example 3: Preparation of an aptasensor for detecting bisphenol A (3)

[0036] On the basis of Example 1, the tube furnace sintering and high-temperature annealing can be performed for 10-30 seconds; the modification in 6-mercaptohexan-1-ol (MCH) solution can also be soaked for 0.5-1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com