Preparation method of carbon nanotube lithium titanate composite cathode material

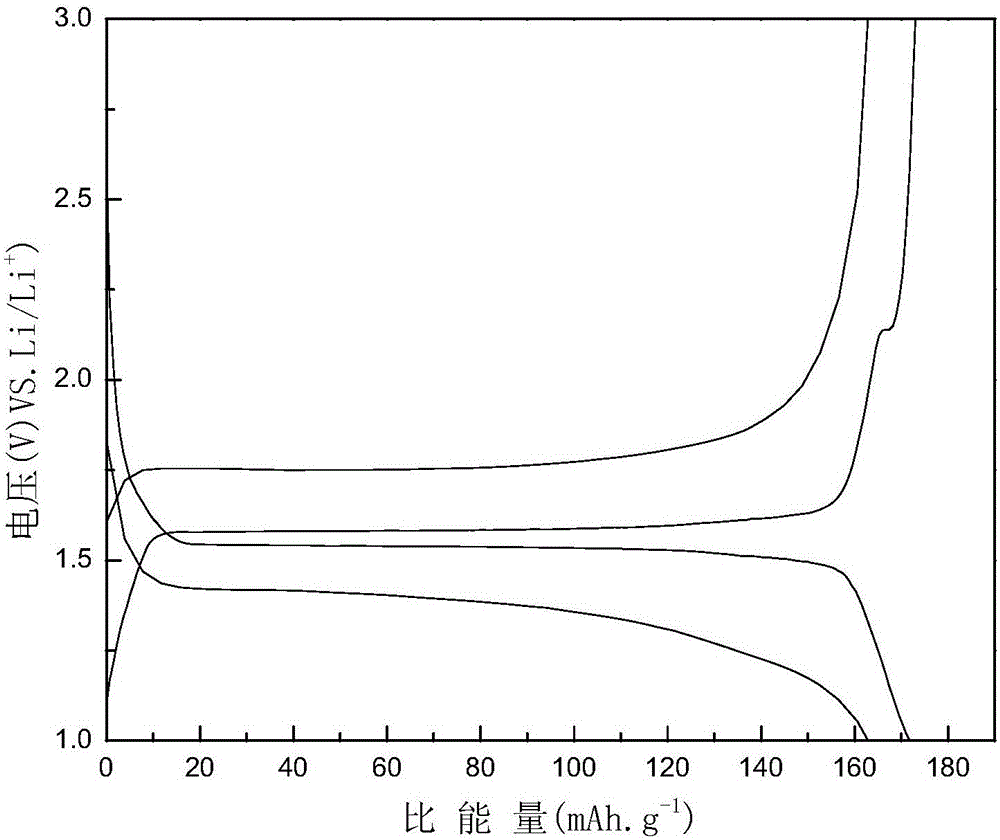

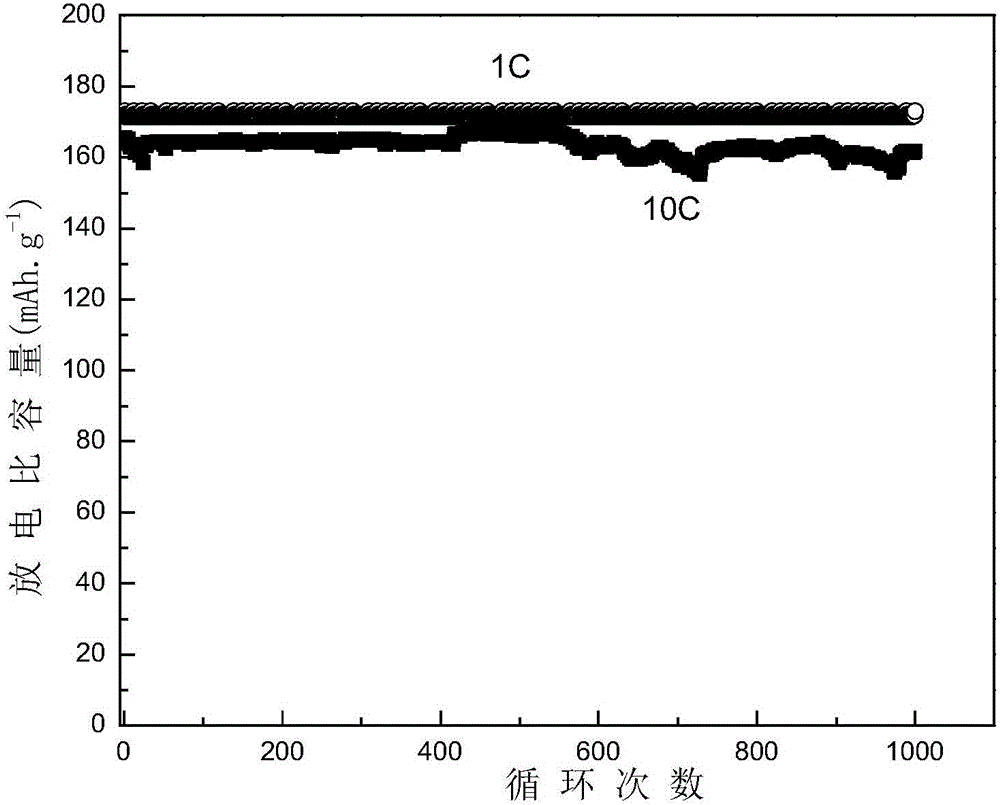

A technology of carbon nanotubes and negative electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low electronic conductivity and ionic conductivity, and achieve good rate performance, good cycle stability, and good high-rate charging. The effect of discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

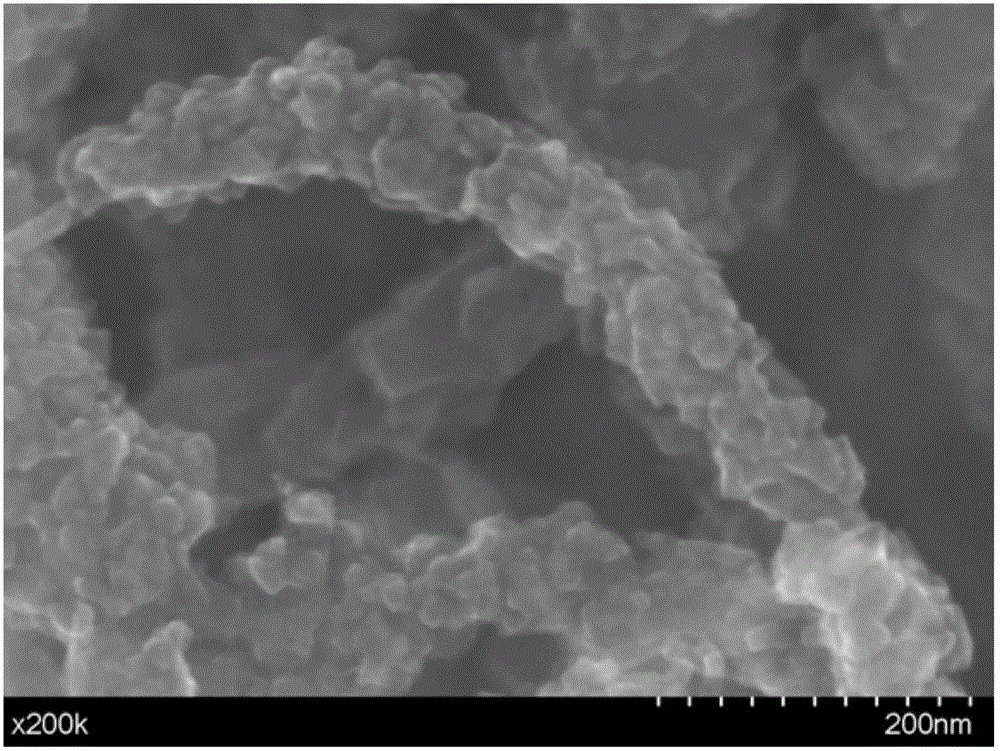

[0031] Add carbon nanotube powder with a diameter of about 2 nm into ethanol and disperse ultrasonically for 1 hour to obtain a solution A with a concentration of 3 g / L. Tetrabutyl titanate and lithium hydroxide were selected as the titanium source compound and the lithium source compound, respectively. According to the molar ratio of lithium to titanium of 0.8:1, 1ml of 30% hydrogen peroxide and 1mmol of tetrabutyl titanate were successively added to 20ml of 0.4M lithium hydroxide aqueous solution, and stirred until completely dissolved. Finally, the above solution was mixed with solution A according to the mass ratio of carbon nanotubes and lithium titanate of 7:93. The resulting mixed solution was poured into a 50ml stainless steel reaction kettle with polytetrafluoroethylene as a liner, sealed and placed in a blast drying oven, and reacted for 12 hours at 150°C. After naturally cooling to room temperature, the reaction product was poured out, centrifuged, washed, and free...

Embodiment 2

[0033] Add carbon nanotube powder with a diameter of about 1 nm into ethanol and disperse ultrasonically for 2 hours to obtain a solution A with a concentration of 1 g / L. Tetrabutyl titanate and lithium acetate were selected as the titanium source compound and lithium source compound, respectively. The above-mentioned tetrabutyl titanate and lithium acetate were dissolved in ethanol to prepare a solution B with a concentration of 1 kg / L. According to the molar ratio of lithium and titanium 0.84: 1, the mass percentage of carbon nanotubes in the composite negative electrode material is 10wt.%, the ethanol solution of solution B and oxalic acid prepared are added to the ethanol solution of carbon nanotubes successively while stirring . The pH value of the above mixed solution was adjusted to 5.6 with ammonia water. Stir at 30°C for 3 hours, then raise the temperature to 60°C, and stir until gelatinous. The wet gel-like substance obtained above is converted into a dry gel prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com