Active layer manufacturing method, oxide thin film transistor and manufacturing method thereof

A technology of oxide film and manufacturing method, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., which can solve the problems of devices not being completely turned off, carrier depletion, and increased power consumption of devices, so as to achieve the utilization of raw materials High efficiency, low power consumption, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

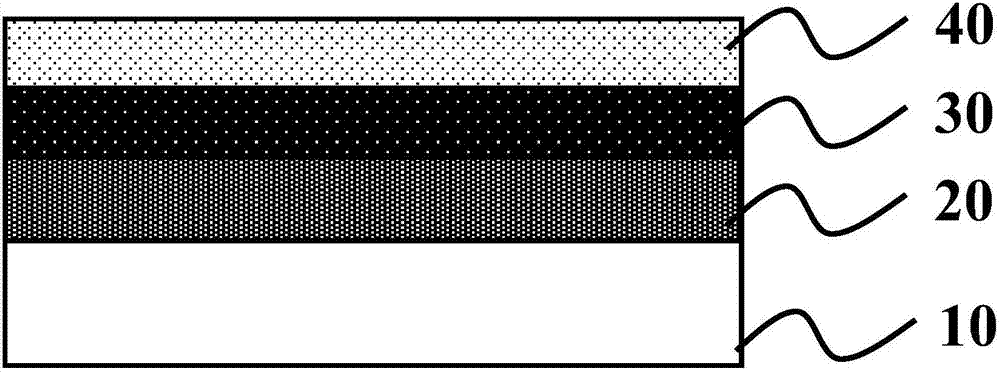

[0074] The oxide thin film transistor described in this embodiment has a bottom-gate top-contact structure, which is specifically prepared by the following steps:

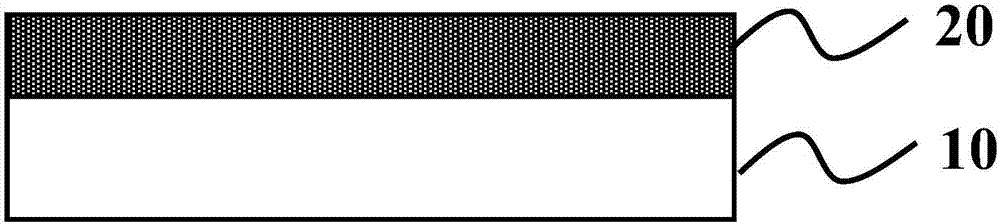

[0075] A layer of Al—Nd alloy thin film with a thickness of 300 nm is prepared on the substrate 10 by sputtering, and the grid 20 is patterned by photolithography.

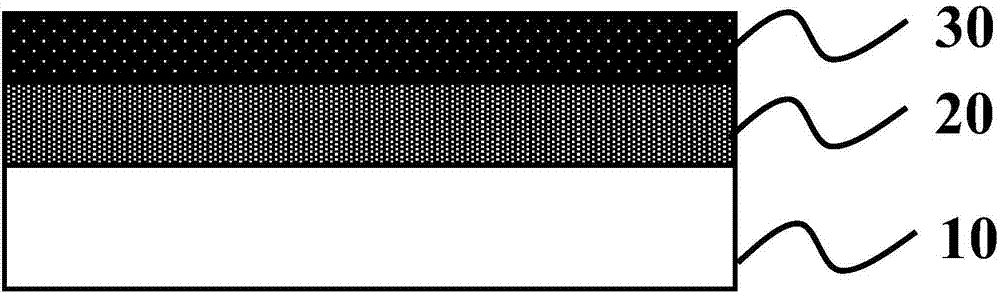

[0076] Prepare Nd:Al with a thickness of 200 nm by anodic oxidation on the above gate 20 2 o 3 thin film to form the gate insulating layer 30; specifically, the substrate 10 prepared above for the gate 20 is placed in an electrolyte solution as an anode, and metal Pt is used as a cathode for anodic oxidation to prepare the gate 20 insulating layer 30. The anodizing method does not require large-scale equipment, and can be performed at room temperature, making it easy to manufacture. In addition, because the oxide layer contains aluminum oxide, its dielectric constant is relatively high, so the threshold voltage of the oxide thin film transistor based...

Embodiment 2

[0086] This embodiment is basically the same as the first embodiment, except that the oxide film in this embodiment is an InZnO (IZO) film.

[0087] Figure 10 is the different oxidation voltage V in this example a The measured transfer characteristic curve of the thin film transistor prepared below, that is, the relationship between the drain current and the gate voltage. The test condition of the curve is: source voltage (V S ) is 0V, the drain voltage (V D ) is constant at 20V, the gate voltage (V G ) from -20V to 20V sweep, test the drain current (I D ).

[0088] from Figure 10 It can be seen from the figure that when the IZO thin film is not anodized in this embodiment, the threshold voltage of the device is relatively negative, and a large negative voltage needs to be applied to the gate 20 to turn off the device. After the anodic oxidation treatment, the threshold voltage of the device showed a positive shift, and with the increase of the oxidation voltage, the ...

Embodiment 3

[0090] This embodiment is basically the same as the first embodiment, except that the oxide film in this embodiment is an In2O3 film.

[0091] Figure 11 is the different oxidation voltage V in this example a The measured transfer characteristic curve of the thin film transistor prepared below, that is, the relationship between the drain current and the gate voltage. The test condition of the curve is: source voltage (V S ) is 0V, the drain voltage (V D ) is constant at 20V, the gate voltage (V G ) from -20V to 20V sweep, test the drain current (I D ).

[0092] from Figure 11 It can be seen that in this example, In 2 o 3 When the film is not anodized, the threshold voltage of the device is relatively negative, and a large negative voltage needs to be applied to the gate 20 to turn off the device. After the anodic oxidation treatment, the threshold voltage of the device showed a positive shift, and with the increase of the oxidation voltage, the threshold voltage cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com