A kind of treatment method of thionyl chloride tail gas

A technology of thionyl chloride and treatment method, which is applied in the field of treatment of thionyl chloride tail gas, can solve the problems of secondary pollution, large equipment investment, and low added value of by-products, and achieve no secondary pollution and high treatment efficiency , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

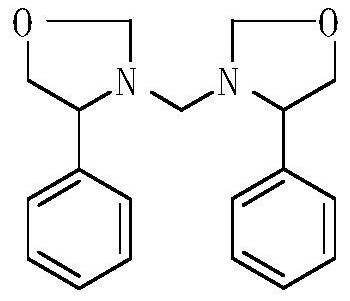

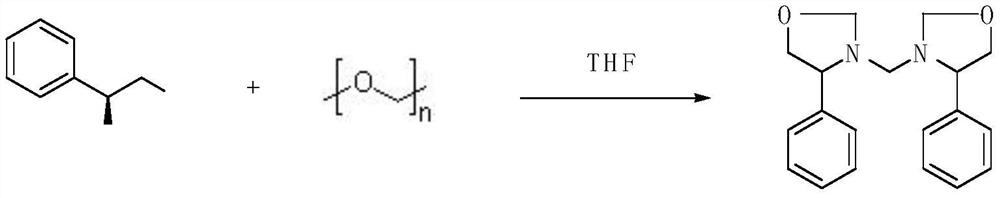

[0041] Wherein the preparation method of organic amine absorbent (I), its steps are as follows:

[0042] First, add paraformaldehyde and L-phenylglycinol in THF, heat up and reflux for 8-12h, and obtain compound (I);

[0043] Secondly, the product can be obtained by distilling and recovering the dry solvent. The synthetic route is as follows:

[0044]

[0045] Wherein the reflux temperature of THF is 60-65 ℃, and the molar weight of described paraformaldehyde converted into formaldehyde is 1.5 times of the molar weight of L-phenylglycinol, and described paraformaldehyde [HO (CH O) nH, wherein n is Polymerization degree, n=10~100].

[0046] The content of sulfur dioxide in the alcohol solution is determined by direct iodometric method (see GB / T11198.12-1989); the content of sulfur dioxide in the tail gas is determined by iodometric method according to the standard HJ / T56-2000 of the State Environmental Protection Administration.

Embodiment 1

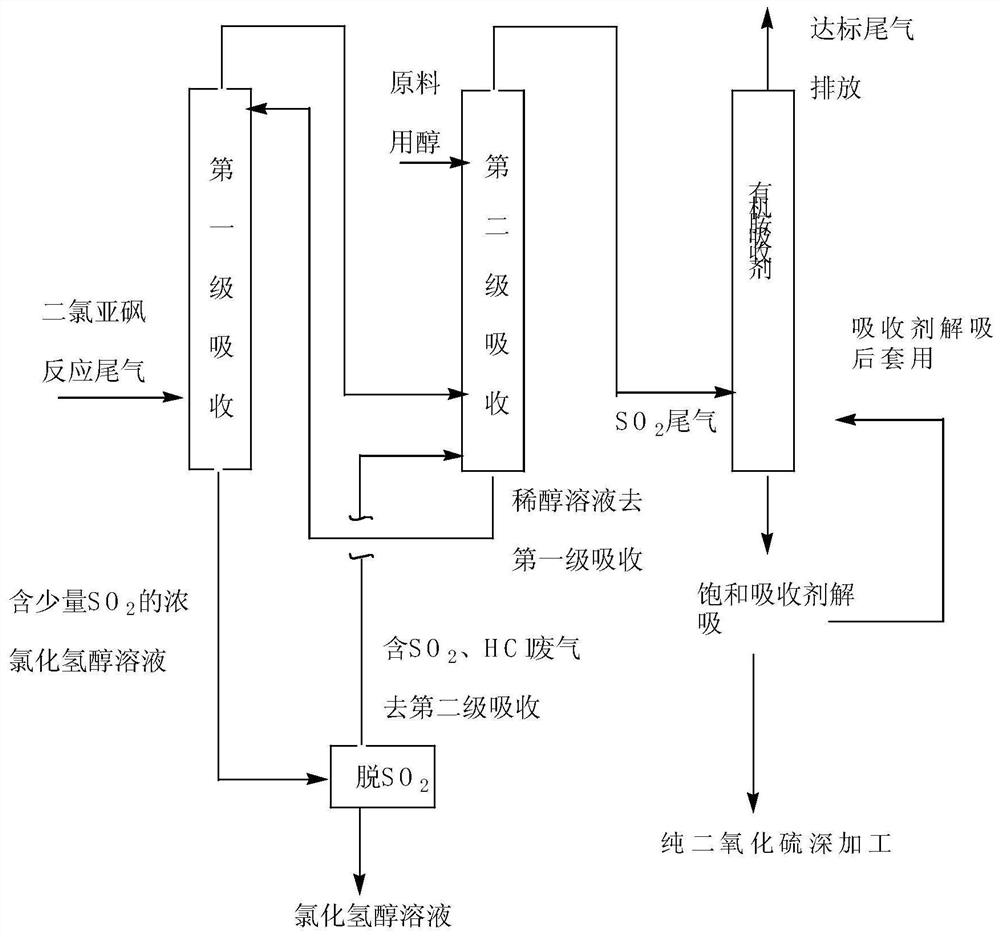

[0048] The tail gas produced by the reaction of one mole of thionyl chloride with alcoholic hydroxyl groups is subjected to secondary absorption by ethanol solution, and then the sulfur dioxide tail gas that is basically free of hydrogen chloride is passed into 350 grams of organic amine absorbent I to absorb at 30°C and then discharged. The waste gas is discharged according to the country Sulfur dioxide content is 5mg / m3 when tested according to the standard HJ / T56-2000 of the State Environmental Protection Administration 3 (to meet the emission requirements of the State Environmental Protection Administration). Then the absorption liquid is heated and desorbed at 130°C for 1 hour, and the obtained absorbent can be recycled, and the released sulfur dioxide can be further processed.

Embodiment 2

[0050]The tail gas produced by the reaction of one mole of thionyl chloride with the hydroxyl group of the alcohol is absorbed by the secondary alcohol and the sulfur dioxide tail gas is removed from the hydrogen chloride. After being collected by the gas collection hood and pressurized by the fan, it is sprayed at 20-25 ° C. The absorbent and tail gas are fully contacted in the packed tower. After the absorption reaction is completed, the purified gas is discharged from the top of the absorption tower; the solution (rich liquid) after absorbing sulfur dioxide is drawn from the bottom of the absorption tower and enters the upper part of the regeneration tower for regeneration. The sulfur dioxide gas released by thermal desorption is sent to the next process for treatment, and the absorbent is recycled.

[0051] The treated purified gas is tested according to the method of the State Environmental Protection Administration standard HJ / T56-2000, and the sulfur dioxide content is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com