Preparation method and application of graphene/carbon nano-tube composite

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of graphene/carbon nanotube composite materials, can solve problems such as uneven dispersion and cumbersome preparation process, and achieve good adsorption performance, simple method, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

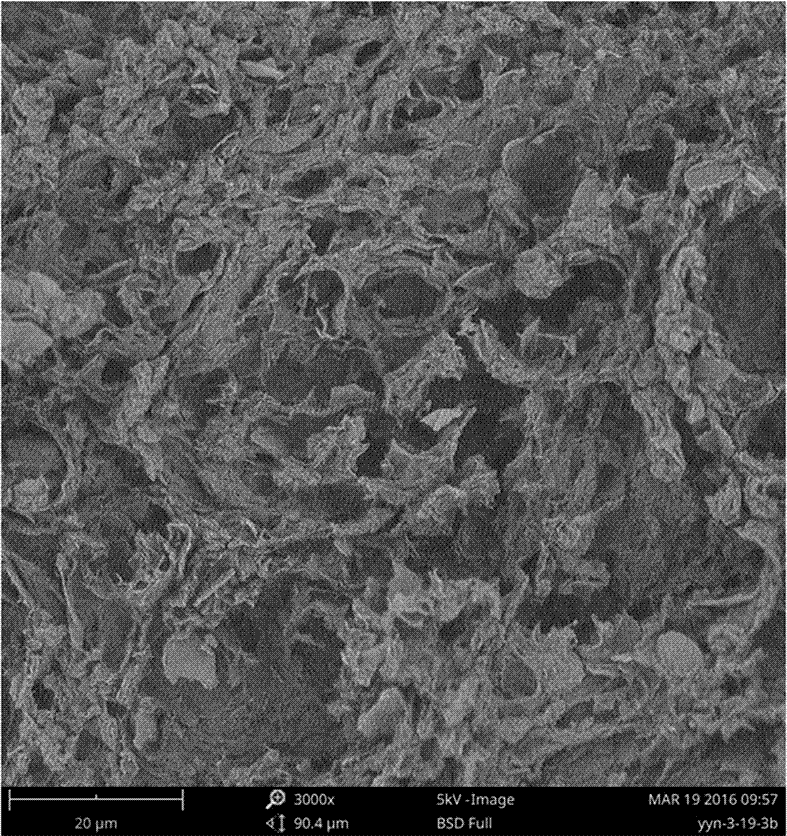

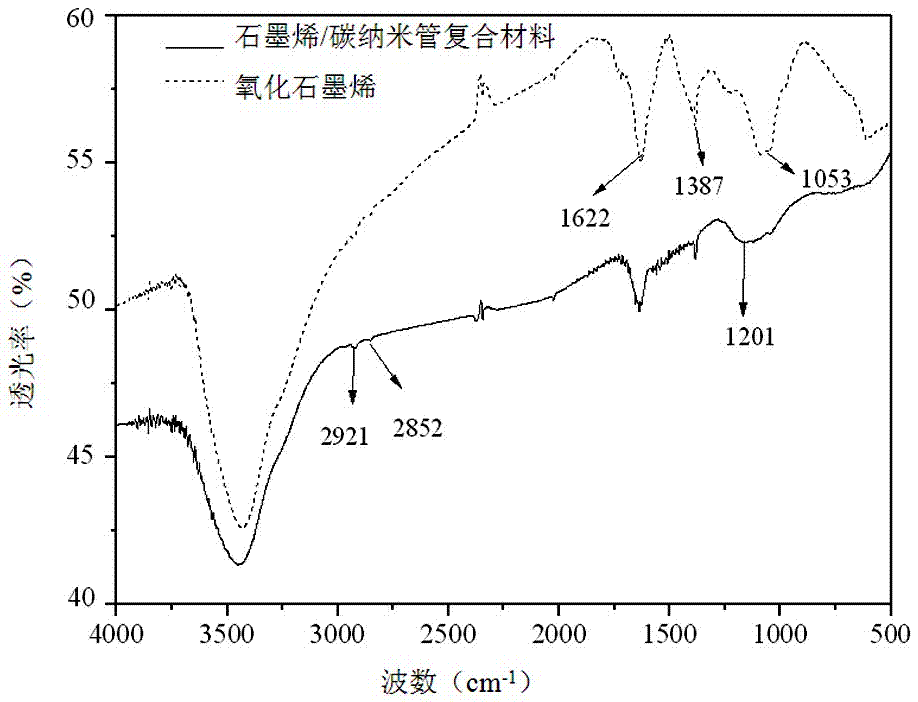

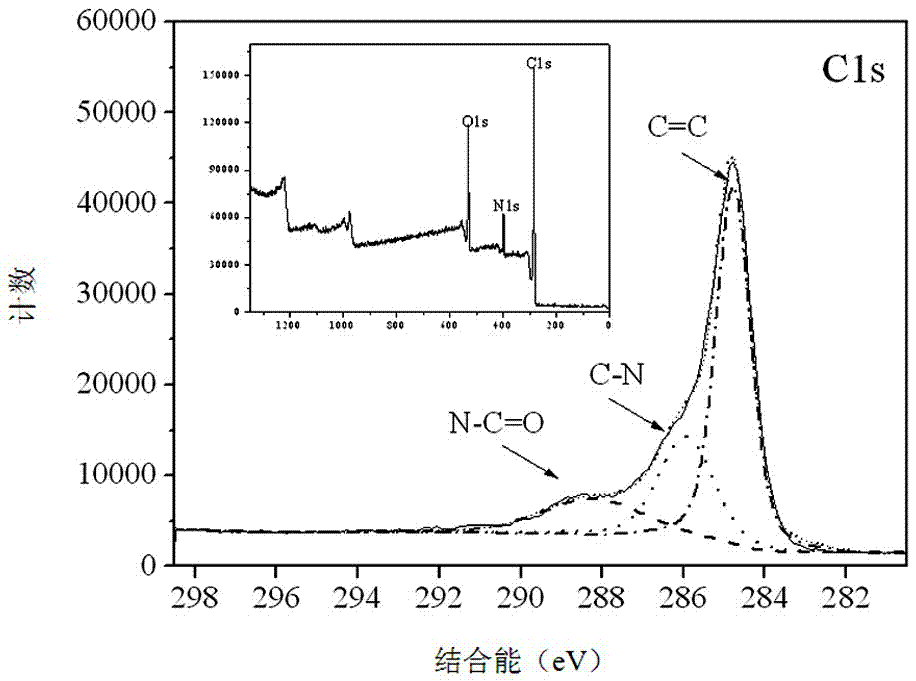

[0034] Under stirring conditions, add 0.857 g of graphite powder and 0.143 g of multi-walled carbon nanotubes into 45 mL of concentrated sulfuric acid with a concentration of 98% in an ice-water bath, stir and disperse for 0.5 h, then slowly add 3 g of potassium permanganate, and stir After 1 h, the ice-water bath was removed, and stirring was continued at room temperature for 24 h; then, under the condition of ice-water bath, 65 mL of deionized water was added to the system, stirred for 2 h, and then 5 mL of 30% hydrogen peroxide and the remaining React with potassium permanganate, stir for 2 h, add deionized water and centrifuge to obtain co-oxidized graphite oxide and carbon nanotube oxide.

[0035] The graphite oxide and carbon oxide nanotubes obtained after centrifugation were added to 600 mL of deionized water for ultrasonic exfoliation and dispersion. The ultrasonic power was 150 W, the ultrasonic frequency was 45 kHz, and the ultrasonic time was 2 h. The graphite oxide ...

Embodiment 2

[0039]Add 1.905 g of graphite powder and 0.095 g of multi-walled carbon nanotubes into 140 mL of concentrated sulfuric acid with a concentration of 98% in an ice-water bath under stirring, stir and disperse for 3 h, then slowly add 12 g of potassium permanganate, and stir for 2 h Then remove the ice-water bath, and continue to stir at room temperature for 6 h; then add 200 mL of deionized water to the system under the condition of ice-water bath, stir for 1 h, then add 20 mL of hydrogen peroxide to react with excess potassium permanganate, and stir for 3 h , and then add deionized water and centrifuge to obtain co-oxidized graphite oxide and carbon nanotube oxide.

[0040] The graphite oxide and carbon oxide nanotubes obtained after centrifugation were added to 1000 mL of deionized water for ultrasonic exfoliation and dispersion. The ultrasonic power was 100 W, the ultrasonic frequency was 100 kHz, and the ultrasonic time was 4 h, so that graphite oxide was exfoliated into grap...

Embodiment 3

[0043] Add 0.8 g of graphite powder and 0.2 g of multi-walled carbon nanotubes into 45 mL of concentrated sulfuric acid with a concentration of 98% and 15 mL of concentrated nitric acid with a concentration of 65% under stirring. The concentrated acid is placed in an ice-water bath, stirred and dispersed for 1 h, then slowly added 4 g of potassium permanganate, stirred for 0.5 h, removed the ice-water bath, and stirred at room temperature for 48 h; then, under the condition of ice-water bath, added 70 mL of deionized water to the system, stirred for 1 h, and then added 8 mL of hydrogen peroxide was reacted with excess potassium permanganate, stirred for 2 h, and then deionized water was added for centrifugation to obtain co-oxidized graphite oxide and carbon nanotubes.

[0044] The graphite oxide and carbon oxide nanotubes obtained after centrifugation were added to 500 mL of deionized water for ultrasonic exfoliation and dispersion. The ultrasonic power was 600 W, the ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com