Fracturing fluid composition for delayed crosslinking in an ultrahigh temperature environment

A technology of delayed cross-linking and composition, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of non-delayed gel formation, poor operation safety, poor sand-carrying ability of fracturing fluid, etc. Construction cost and effect of reducing formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

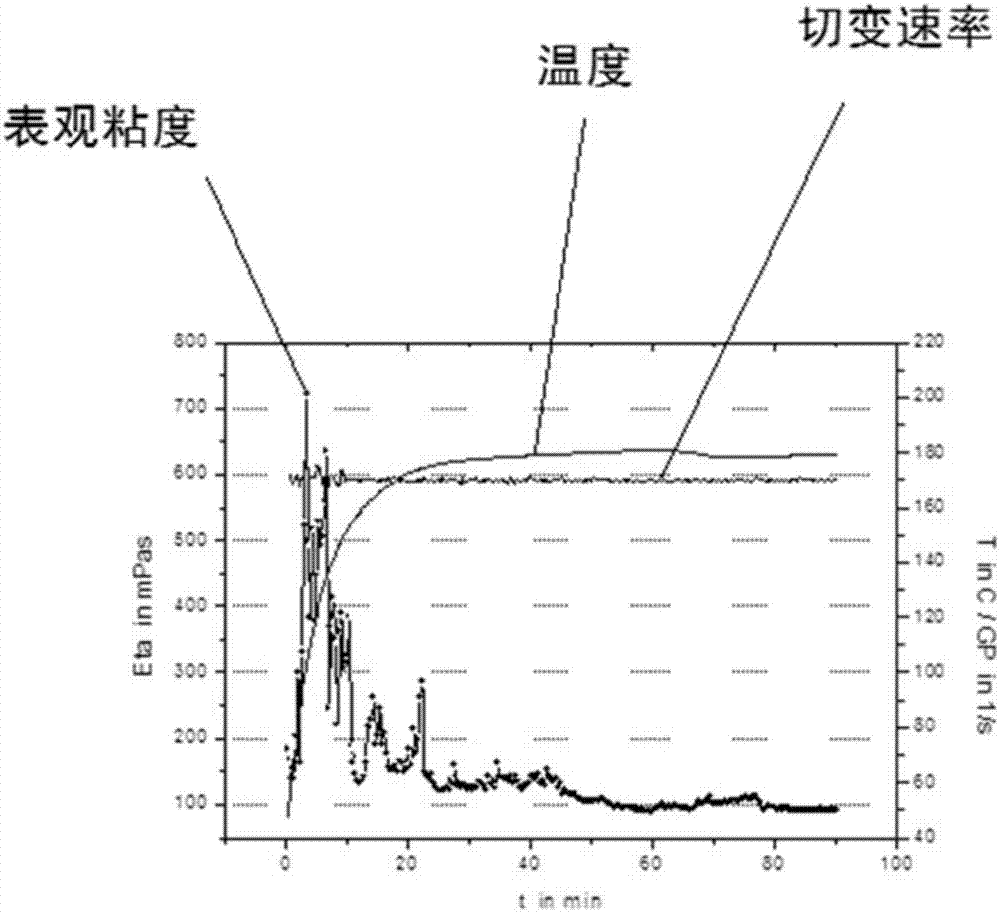

Embodiment 1

[0033]Dissolve 3.6 grams of carboxymethylhydroxypropyl guar gum WGA-5 in 1000ml of water, add 0.002 grams of bactericide BioClear-1000, and let it stand for 2 hours to form a base liquid; at room temperature, add 1g of quaternary ammonium salt-type clay stabilizer ClayTreat -3C, 1g of 50% glutaraldehyde aqueous solution, 0.5g of sodium carbonate, and 1g of NE-940 are stirred and dissolved, take 400ml of base liquid in a Warring mixer, start stirring, and add 0.4g of delayed cross-linking agent ZXL -LTD (the weight ratio of tetra-n-butyl zirconate, glyoxal, glycerol and polyethylene polyamine is 1:3:2.5:3.5, add water to form a homogeneous phase and then heat the reaction, the reaction temperature is 85 ° C, the reaction time 6 hours; Wherein, polyethylene polyamine mixture is the mixture of ethylenediamine, triethylenetetramine and pentaethylenehexamine, and its mixing ratio is mass parts 1:2:1.5), and record vortex closing time is 125 seconds, becomes The glue is uniform, and...

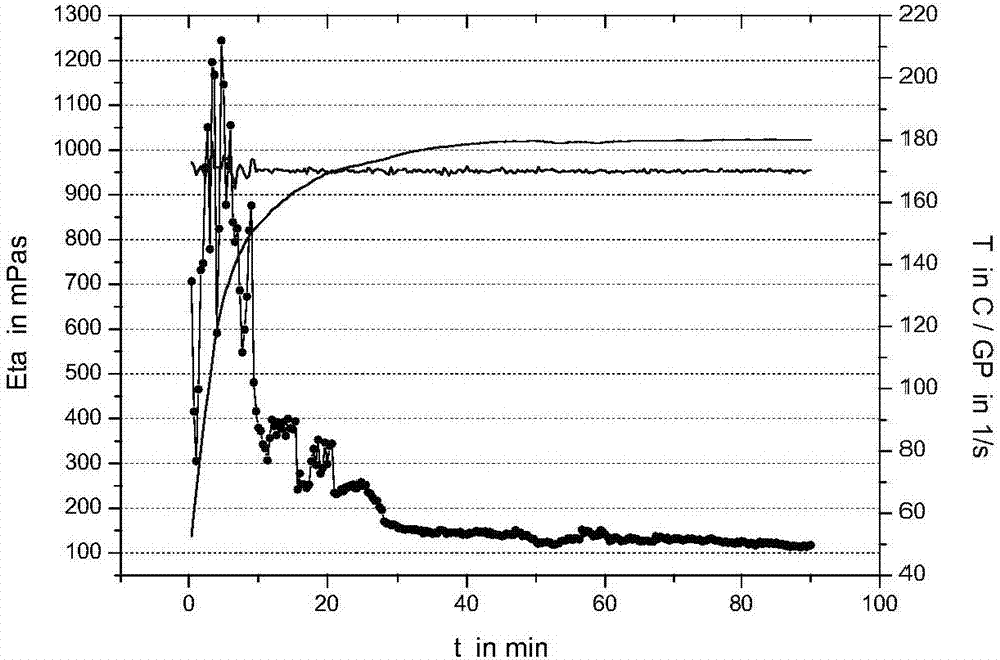

Embodiment 2

[0035] Dissolve 4.2 grams of carboxymethylhydroxypropyl guar gum WGA-5 in 1000ml of water, add 0.002 grams of fungicide BioClear-1000, and let it stand for 2 hours to form a base liquid; at room temperature, add 1g of quaternary ammonium salt-type clay stabilizer ClayMaster -5C, 0.5g 25% potassium hydroxide solution, 1g FlowGas stirring and dissolving, take 400ml of base liquid in the Warring mixer, start stirring, add 2.0g delayed crosslinking agent (triisopropyl chromium (III) The weight ratio of acid ester, glyoxal, glycerin and polyvinyl polyamine is 1:2:4:2.5, add water to form a homogeneous phase and then heat the reaction, the reaction temperature is 140°C, and the reaction time is 3 hours; among them, polyethylene The polyamine mixture is a mixture of ethylenediamine and tetraethylenepentamine, the mixing ratio is 1:2 by mass), the recorded vortex closing time is 267 seconds, the gel is uniform, and it can be hung after 11 minutes of vortex closing. Take 45 grams of th...

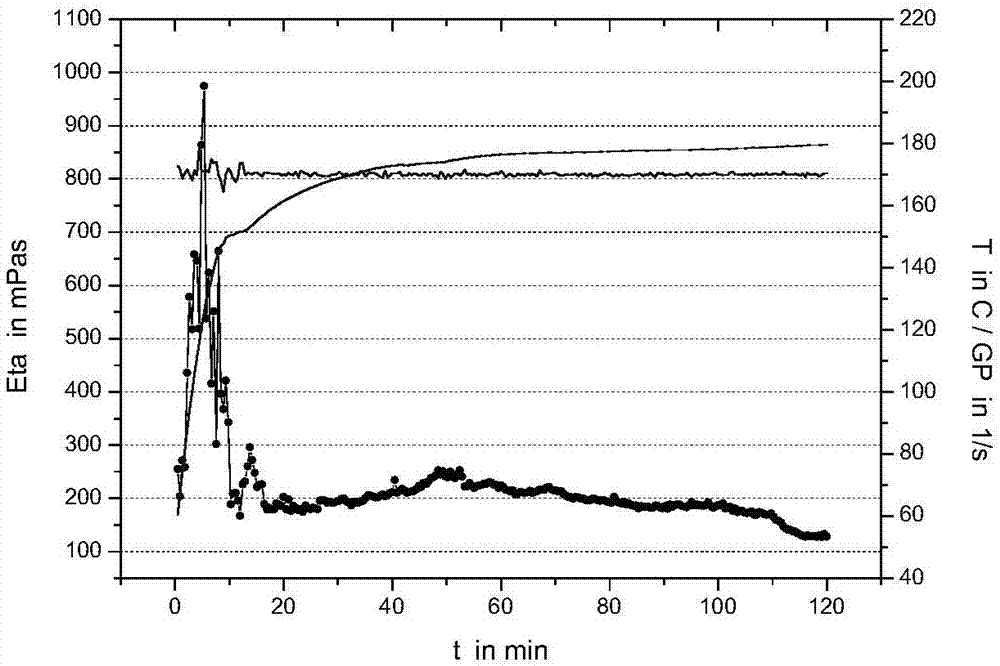

Embodiment 3

[0037] Dissolve 4.8 grams of carboxymethylhydroxypropyl squash gum CGA-7 in 1000ml of water, add 0.002 grams of bactericide BioClear-1000, and let it stand for 2 hours to form a base solution; at room temperature, add 0.5 grams of tetramethylammonium chloride, 1 g of 50% glutaraldehyde aqueous solution, 0.5 g of 25% potassium hydroxide solution, 1 gram of NE-118 and 2 g delayed crosslinking regulator CTD (ie: 50% sorbitol aqueous solution). After stirring and dissolving, take 400ml of base liquid in a Warring mixer, start stirring, add 0.8g of delayed crosslinking agent TXL-LTD (tetra-n-butyl titanate, glyoxal, glycerin and polyethylene polyamine) The weight ratio is 1:4:3:2, add water to form a homogeneous phase and then heat the reaction, the reaction temperature is 85°C, and the reaction time is 6 hours; among them, the polyethylene polyamine is pentaethylene hexamine), and the recorded vortex closure time is 573 seconds, the gel is uniform, and it can be hung after 12 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com