Trench gate metal oxide field effect transistor and manufacturing method thereof

A field-effect transistor, oxide technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as trap trapping, device threshold voltage drift, and large delay time, and achieve enhanced depletion and parasitic capacitance. The effect of rapid decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

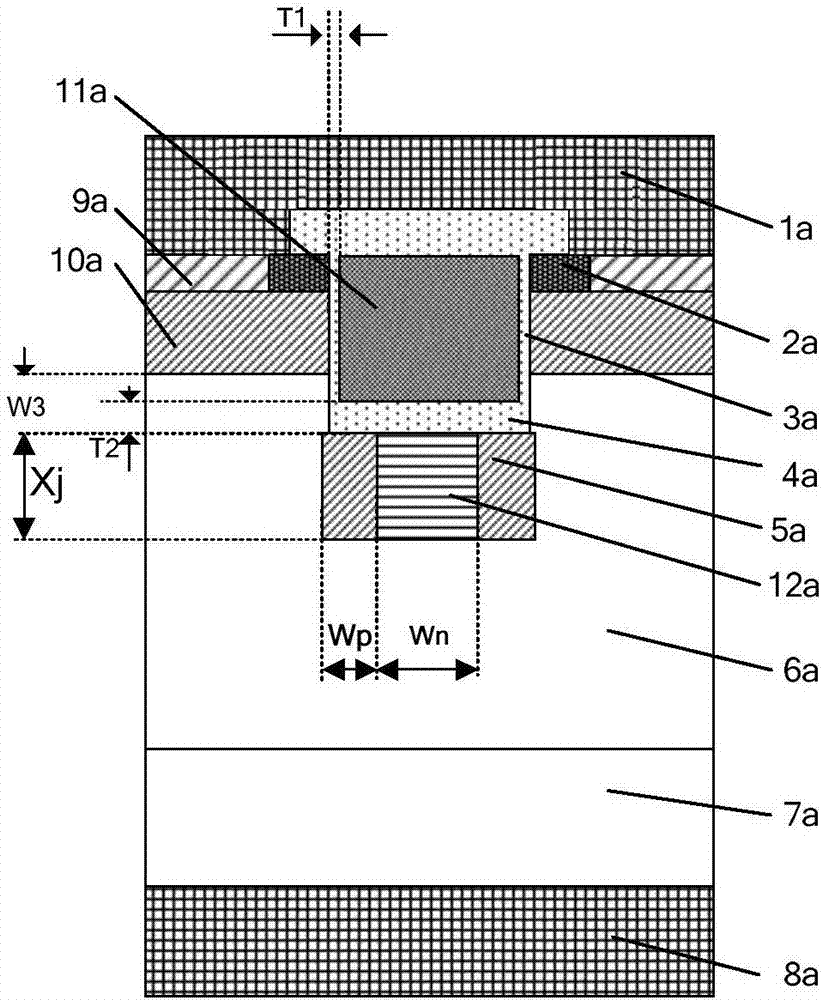

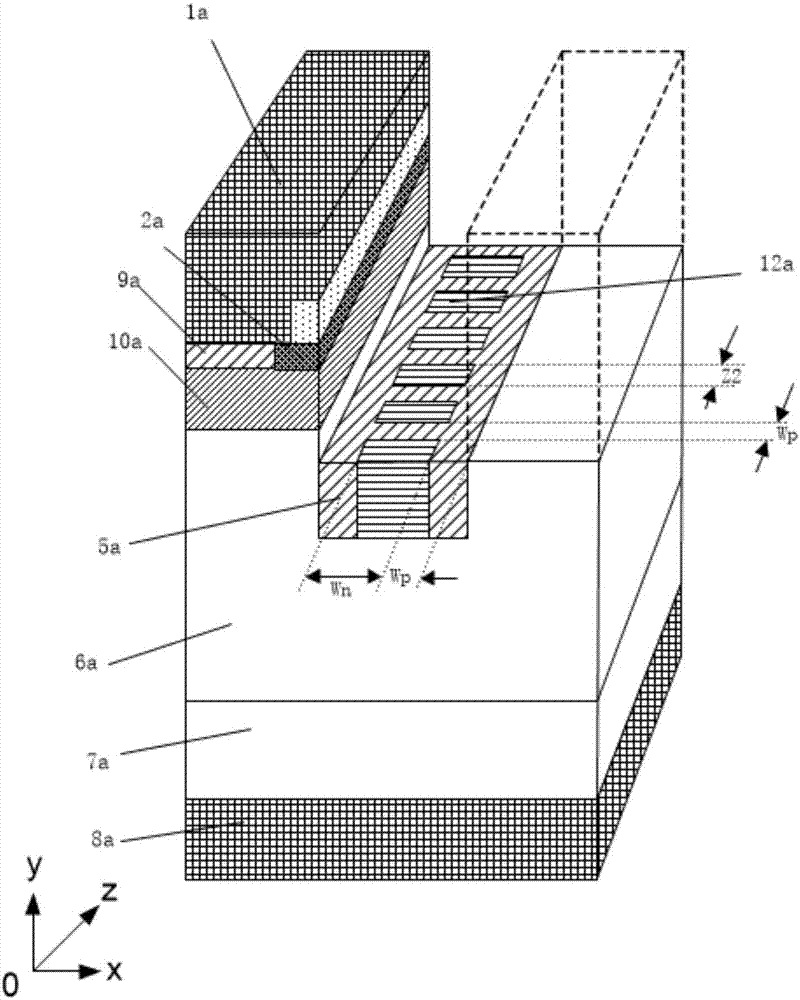

[0043] Such as figure 1 Shown is a trench gate metal oxide field effect transistor provided by Embodiment 1 of the present invention, comprising a front metal electrode 1a, a back metal electrode 8a, an N-type single crystal substrate 7a on the back metal electrode 8a, and an N-type single crystal substrate 7a on the back metal electrode 8a. The N-type epitaxial layer 6a formed on the N-type single crystal substrate 7a, and the first P-type doped region 10a formed on the N-type epitaxial layer 6a. A vertical groove is arranged at the central part of the N-type epitaxial layer 6a and the first P-type doped region 10a, and a grid 11a is arranged in the groove, and the depth of the grid 11a is larger than that of the first P-type doped region 10a. The junction depth is deeper, and the difference between the two is W 3 -T 2 The first dielectric layer 3a is between the sidewall of the gate 11a and the first P-type doped region 10a, and the second dielectric layer 4a is between th...

Embodiment 2

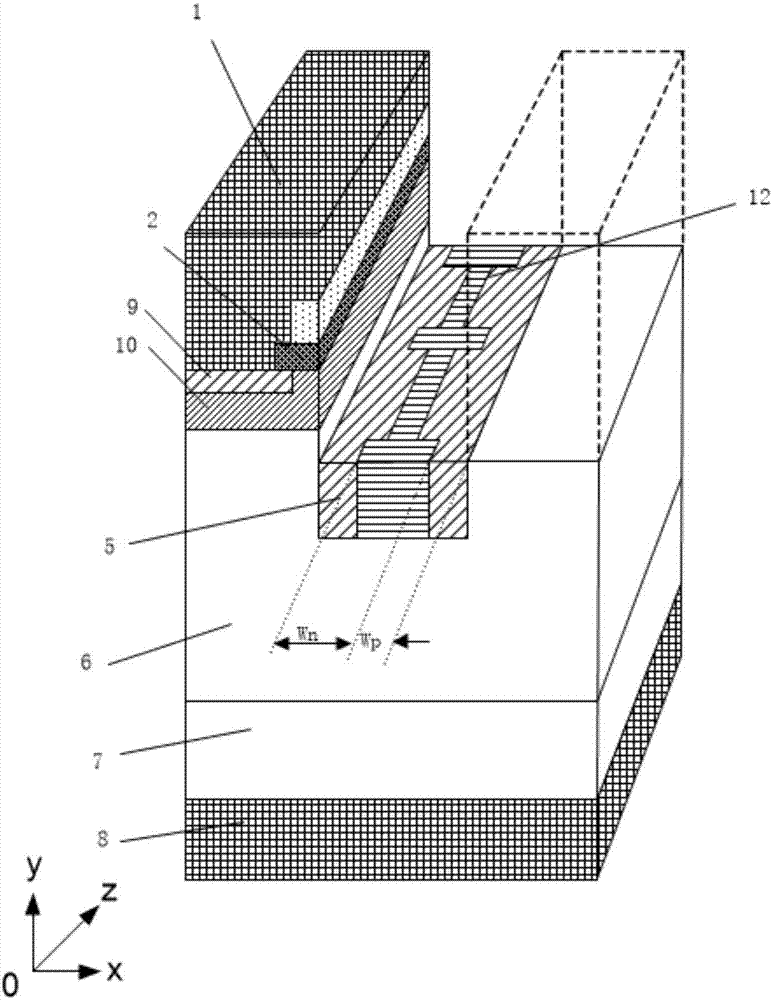

[0056] Such as Figure 5 Shown is a trench gate metal oxide field effect transistor provided by Embodiment 2 of the present invention, comprising a front metal electrode 1b, a back metal electrode 8b, an N-type single crystal substrate 7b on the back metal electrode 8b, and an N-type single crystal substrate 7b on the back metal electrode 8b. An N-type epitaxial layer 6b formed on the N-type single crystal substrate 7b, and a first P-type doped region 10b formed on the N-type epitaxial layer 6b. A vertical groove is arranged at the central part of the N-type epitaxial layer 6b and the first P-type doped region 10b, and a gate 11b is arranged in the groove, and the depth of the gate 11b is larger than that of the first P-type doped region 10b. The junction depth is deeper, and the difference between the two is W 3 -T 2 The first dielectric layer 3b is between the sidewall of the gate 11b and the first P-type doped region 10b, and the second dielectric layer 4b is between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com