Anti-adhesion compound dural patch and preparation method thereof

An anti-adhesion and dura mater technology, applied in the field of medical materials, can solve the problems of limited anti-adhesion and anti-cerebrospinal fluid leakage, and achieve the effects of preventing cerebrospinal fluid leakage, preventing fiber shedding, and accelerating repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

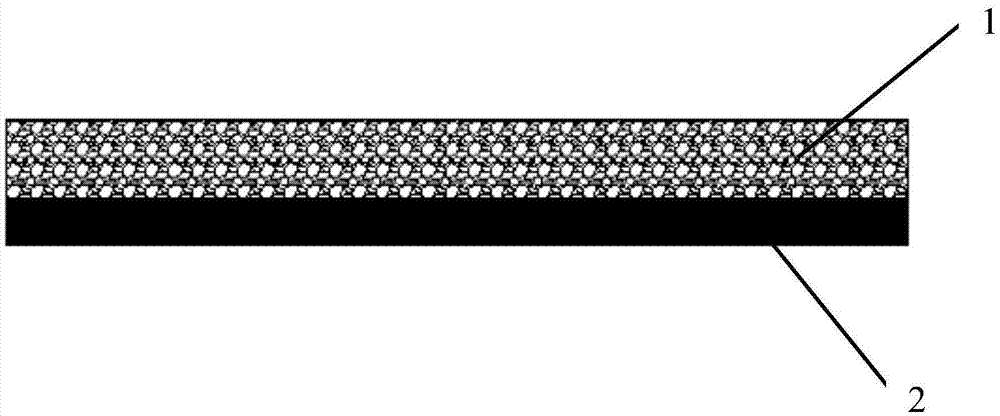

[0024] figure 1 Be the structure of dura mater patch in the present embodiment, as figure 1 As shown, the dura mater patch is composed of a functional layer 1 and an anti-adhesion layer 2 . The functional layer 1 is a nanofiber film, and the anti-adhesion layer 2 is a dense film.

[0025] (1) Preparation of dense film: select polyethylene glycol-modified polylactic acid, the proportion of polyethylene glycol is 20%, as a copolymerized polymer raw material, with a weight average molecular weight of 200,000, dissolved in ethyl acetate, ultrasonically vibrated, filtered, press The ratio is added to a polytetrafluoroethylene plate with grooves, cast to form a film, placed in a vacuum drying oven, and vacuum-dried for 24 hours to obtain a soft and dense film with a thickness of 0.03 mm, which is the anti-adhesion layer 2.

[0026] (2) Preparation of composite structure: preparation of electrospinning stock solution: select chitosan and polylactic acid at a ratio of 50:50, dissolv...

Embodiment 2

[0031] (1) Preparation of dense film: select caprolactone-modified polylactic acid, the proportion of caprolactone is 15%, as a copolymerized polymer raw material, with a weight average molecular weight of 200,000, heated and blown into a film to obtain a soft and dense film with a thickness of 0.02mm membrane.

[0032] (2) Preparation of composite structure: preparation of electrospinning stock solution: choose polylactic acid and PEG6000 in a ratio of 70:30 and dissolve in chloroform, ultrasonically vibrate, filter, and set aside.

[0033] Add the above solution into the injection device of the spinning device, adjust the injection pump rate to 10ml / h; the voltage of the high voltage generator is 22KV, the negative pressure of the receiving device is 5KV, and the electrospinning is started to obtain the functional layer, and the functional layer and the anti-adhesion layer Cross-linking to prepare a cross-linked composite structure with the anti-adhesion layer as the base an...

Embodiment 3

[0037] Carry out rabbit animal experiment with the dura mater patch that embodiment 1, 2 makes

[0038] Select healthy rabbits, artificially create part of the dura mater defect under general anesthesia, then implant the dura mater patch for repair, suture and fix. After the operation, the animals were fed routinely and observed regularly. Six months after the operation, tissue samples were extracted according to standard requirements, and case slides were prepared. The material was obviously degraded, with a very small amount of residue, increased collagen fibers, and slight cystic wall formation at the interface; 12 months after the operation, the tissue specimen was cut, no material residue, the dura mater healed well, only traces of sutures were seen, the brain tissue was normal, and there was no abnormality reaction.

[0039] The anti-adhesion composite dura mater patch and the preparation method thereof of the present invention, the layer facing the brain is designed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com