A kind of ABS non-migration-resistant high flame-retardant PVC material and its preparation method

A PVC material and high flame retardant technology, applied in the field of polymer materials, can solve the problems of easy migration of PVC, cracking of ABS product layers, and reduced product quality, and achieve the effects of high cost performance, low cost and good processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

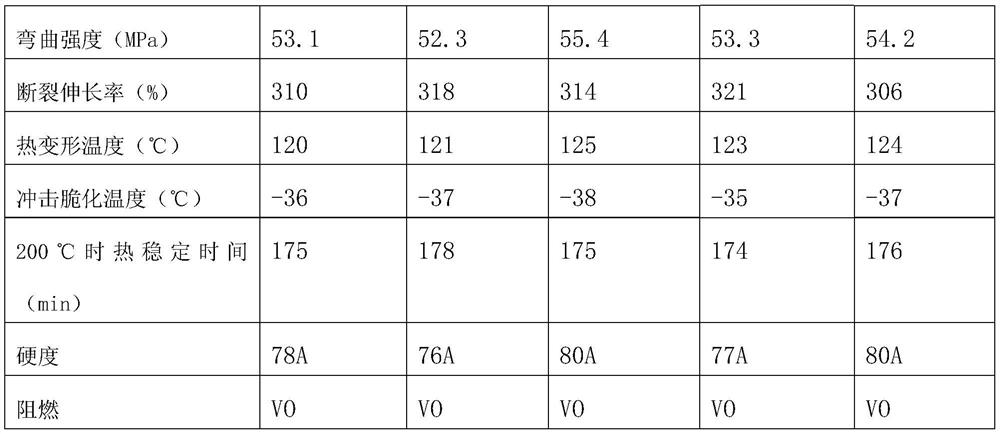

Examples

Embodiment 1

[0023] Embodiment 1: A kind of anti-ABS non-migration high flame-retardant PVC material provided in this embodiment is made of raw materials comprising the following components in parts by weight: 100 parts of polyvinyl chloride powder, environmentally friendly plasticizer 15 parts of agent, 15 parts of titanate modified wollastonite powder, 3 parts of stabilizer, 10 parts of flame retardant, and 6 parts of processing aid; among them, the environmentally friendly plasticizer is made of epoxy pupa oil and multifunctional esters. The plasticizer is compounded according to the mass ratio of 1:2. The multifunctional ester plasticizer is obtained by reacting cyclopentadiene and maleic anhydride through D-A reaction and then reacting with polyols through esterification. The stabilizer is Calcium stearate, zinc stearate and antioxidant 1010 are compounded at a mass ratio of 1:1:1. The flame retardant is diphenyl polyphosphate and surface treated with dimethylsilane and methylhydrosila...

Embodiment 2

[0030] Embodiment 2: A kind of anti-ABS non-migration high flame-retardant PVC material provided by this embodiment is made of raw materials comprising the following components in parts by weight: 100 parts of polyvinyl chloride powder, environmentally friendly plasticizer 50 parts of agent, 65 parts of titanate modified wollastonite powder, 8 parts of stabilizer, 30 parts of flame retardant, and 10 parts of processing aid; among them, the environmentally friendly plasticizer is made of epoxy pupa oil and multifunctional esters. The plasticizer is compounded according to the mass ratio of 2:3. The multifunctional ester plasticizer is obtained by reacting cyclopentadiene and maleic anhydride with D-A and then reacting with polyols through esterification. The stabilizer is Calcium stearate, zinc stearate and antioxidant 1010 are compounded at a mass ratio of 2:1:2. The flame retardant is diphenyl polyphosphate and surface treated with dimethylsilane and methylhydrosilane. The mo...

Embodiment 3

[0035] Embodiment 3: A kind of anti-ABS non-migration high flame-retardant PVC material provided in this embodiment is made of raw materials comprising the following components in parts by weight: 100 parts of polyvinyl chloride powder, environmentally friendly plasticizer 90 parts of agent, 45 parts of titanate modified wollastonite powder, 5 parts of stabilizer, 30 parts of flame retardant, and 2 parts of processing aid; wherein, the environmentally friendly plasticizer is made of epoxy pupa oil and multifunctional ester The plasticizer is compounded according to the mass ratio of 1:2. The multifunctional ester plasticizer is obtained by reacting cyclopentadiene and maleic anhydride with D-A and then reacting with polyols through esterification. The agent is composed of calcium stearate, zinc stearate and antioxidant 1010 at a mass ratio of 1.2:1:2, and the flame retardant is diphenyl polyphosphate and hydrogenated with dimethylsilane and methyl Silane surface modified magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com