Method of extracting biochemical fulvic acid from papermaking black liquid through biological fermentation

A technology for biochemical fulvic acid and papermaking black liquor is applied in the field of waste recycling, which can solve the problems of large equipment investment and high operating costs, and achieve the effects of low cost, reduced production cost and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

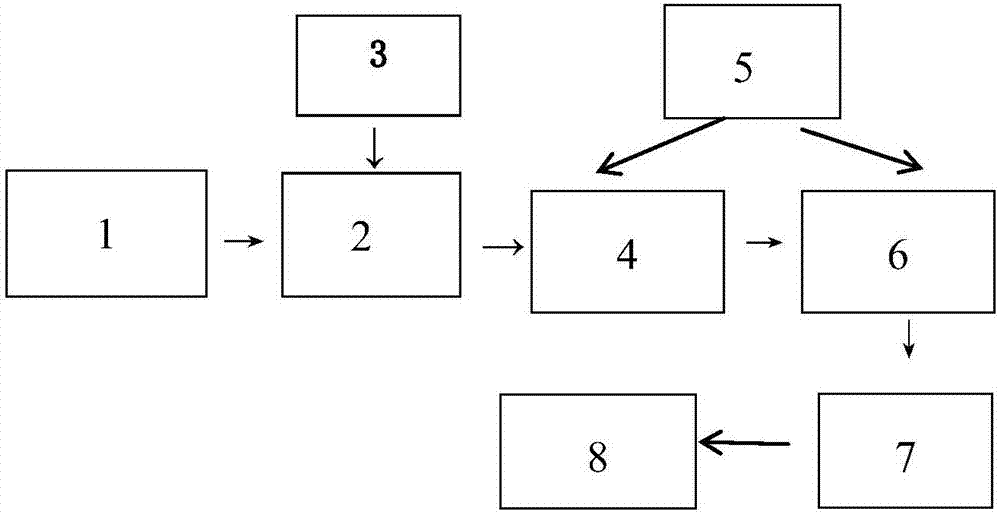

Image

Examples

Embodiment 1

[0020] Filter the papermaking black liquor to remove the residue. Acidity is adjusted to pH and be 9, add its volume ratio 1% bacterial enzyme mixed solution (Phanerochaete chrysosporium and Coriolus versicolor, trichosporon and lignin peroxidase) in papermaking black liquor, Add appropriate amount of urea to provide nitrogen source, and control the carbon-nitrogen ratio (C / N) 25:1. The water content is controlled at 65%, the temperature is controlled at 25 degrees, and proper ventilation is provided to supply the oxygen required by the microorganisms, and the fermentation lasts for 18 days. Take the fermentation mixture in the reaction kettle, add a NaOH solution with a concentration of 0.1mol / L (the volume ratio of the NaOH solution to the fermentation mixture is 1:10), feed nitrogen gas for 5-10min, and drive away O 2 , react at constant temperature for 4 hours, after the reaction is completed, let it stand in the dark for 10 hours, and centrifuge at 10000r / min for 10min t...

Embodiment 2

[0022] Filter the papermaking black liquor to remove the residue. Adjust the acidity to pH 8, add 2% by volume of bacteria and enzyme mixture (Phanerochaete chrysosporium and Trametes versicolor, Pseudomonas PKE117, laccase) to the papermaking black liquor, add an appropriate amount of urea Provide a nitrogen source and control the carbon-to-nitrogen ratio (C / N) to 30:1. The water content is controlled at 55%, the temperature is controlled at 35 degrees, and proper ventilation is provided to supply the oxygen required by the microorganisms, and the fermentation is carried out for 12 days. Take an appropriate amount of fermented papermaking black liquor in a reaction kettle, add 0.1mol / L NaOH solution (volume ratio 1:10), feed nitrogen gas for 5-10min, and drive away O 2 , constant temperature reaction for 4 hours. After the reaction was completed, it was left to stand in the dark for 10 hours, and the residue was removed by centrifugation at 10000r / min for 10min. Adjust the...

Embodiment 3

[0024]Filter the papermaking black liquor to remove the residue. Acidity adjusted to pH is 7, adds its volume ratio 3% bacterium enzyme mixed solution (Phanerochaete chrysosporium, Trichosporium yeast, Pseudomonas PKE117, manganese peroxidase) in papermaking black liquor, adds Appropriate amount of urea provides nitrogen source, and the carbon-nitrogen ratio (C / N) is controlled at 35:1. The water content is controlled at 60%, the temperature is controlled at 25 degrees, and proper ventilation is provided to supply the oxygen required by the microorganisms, and the fermentation lasts for 16 days. Take an appropriate amount of fermented papermaking black liquor in a reaction kettle, add 0.1mol / L NaOH solution (volume ratio 1:10), feed nitrogen gas for 5-10min, and drive away O 2 , close the lid tightly, and react at constant temperature for 4 hours. After the reaction was completed, it was left to stand in the dark for 10 hours, and the residue was removed by centrifugation at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com