Nitrogen-rich doped porous structural carbon material and preparation method and application thereof

A porous carbon material and porous structure technology, applied in the field of porous materials, can solve the problems of complex preparation process of high-capacity negative electrode materials, limited specific capacity of negative electrode materials, and difficulty in large-scale production, so as to improve electrochemical performance and lithium storage performance , short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

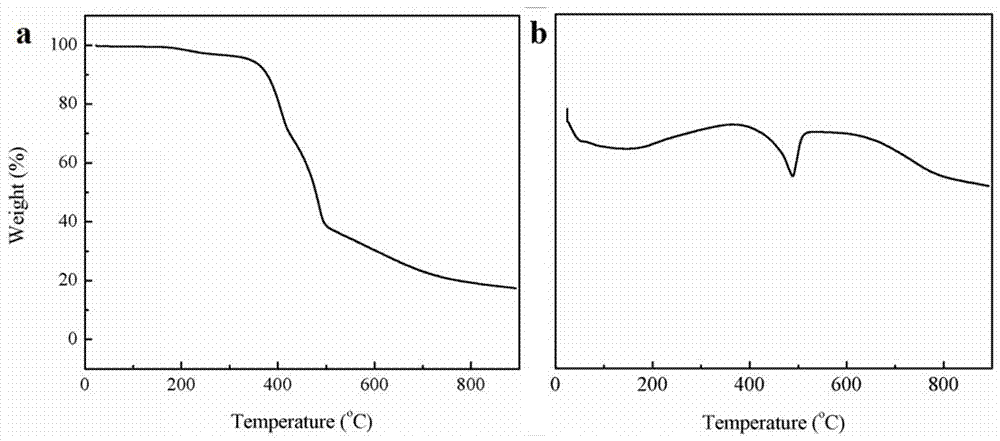

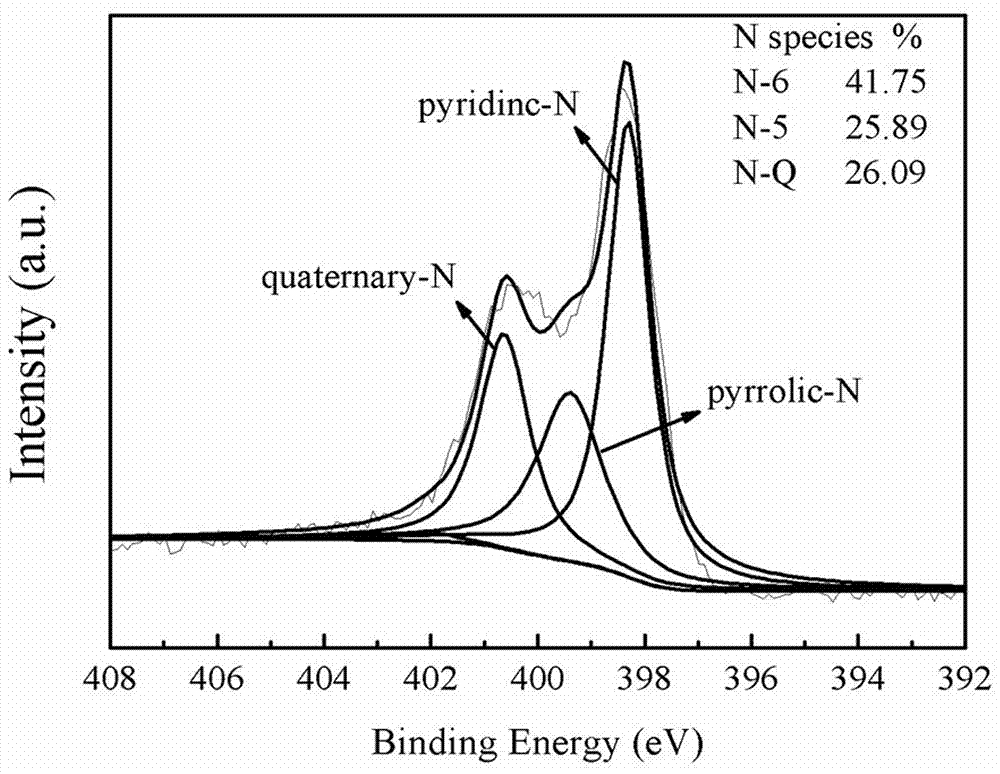

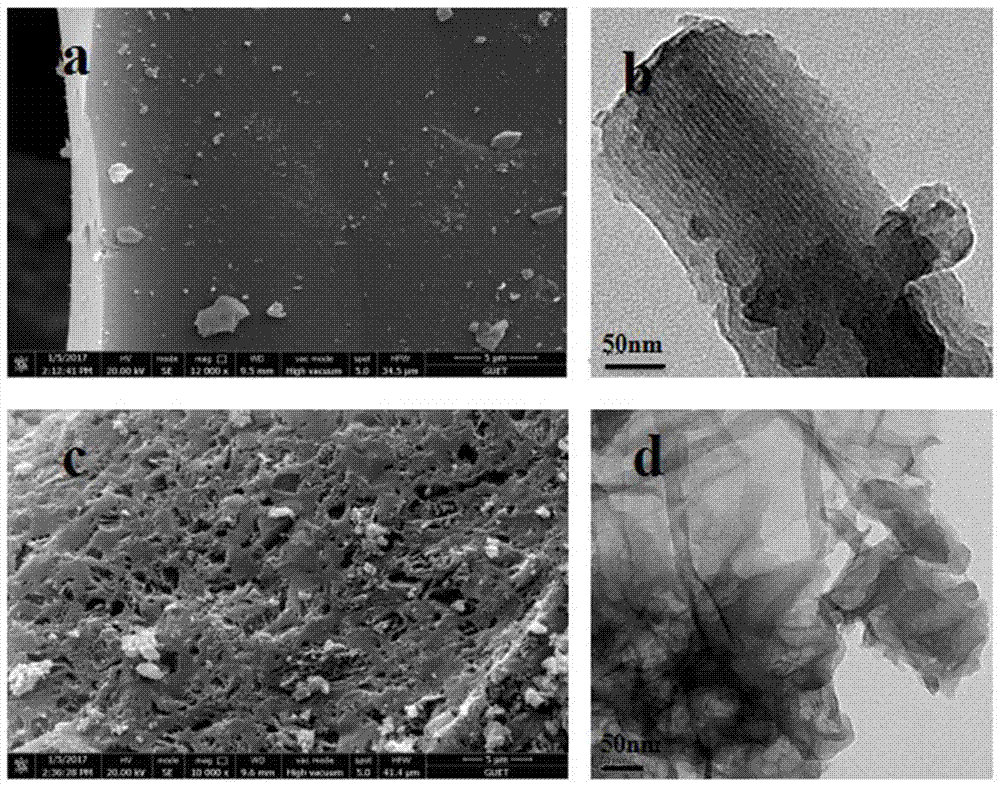

[0040] A preparation method of a nitrogen-rich doped porous structure carbon material is as follows:

[0041] Step (1) Dissolve 20 g of phenol into 4.26 g of NaOH solution (20 wt%), stir at 50 °C for 10 min, then add 35.4 g of formaldehyde solution (37 wt %) dropwise, and react at 75 °C for 60 min . After cooling, adjust the pH to neutral with 1 M dilute hydrochloric acid, then put it in a vacuum oven at 40°C for drying, and dissolve the final product in ethanol to prepare a water-soluble phenolic resin solution with a concentration of 20 wt%.

[0042] Step (2) Dissolve 1 g of F127 and 2 g of guanine in a mixed solution of 10 g of deionized water and 20 g of absolute ethanol, then add 5 g of the phenolic resin ethanol solution described in step (1) to the above solution , stirred at 35 °C for 30 min, after the reaction, the light yellow solution was introduced into a petri dish, dried at 50 °C for 6 h, and then placed in an oven at 100 °C for 24 h;

[0043] Step (3) Grind th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com