Method for preparing large size lead halide cesium perovskite crystal

A lead halide cesium perovskite, large-scale technology, applied in chemical instruments and methods, inorganic chemistry, lead compounds, etc., can solve the problems of low yield, high cost, and inability to prepare on a large scale, and achieve high yield, The effect of stable properties and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 0.147g PbBr 2 Dissolve in 5mL of dimethylamide (DMF), stir until completely dissolved;

[0033] (2) Weigh out 0.0851g of CsBr and dissolve it in 5mL of dimethylamide (DMF) and add surfactants (0.5mL of oleic acid and 0.25mL of oleylamine), and heat the solution to 150°C for 1 hour at a constant temperature, and then cool to Room temperature

[0034] (3) The obtained 5mLPbBr 2 The solution was preheated to 50℃, and then added to the prepared 5ml cesium salt solution (Cs + : Pb 2+ The molar ratio is 1:1), the mixed solution is gradually heated to 70°C, and after reacting for 3 hours, a precursor solution is obtained;

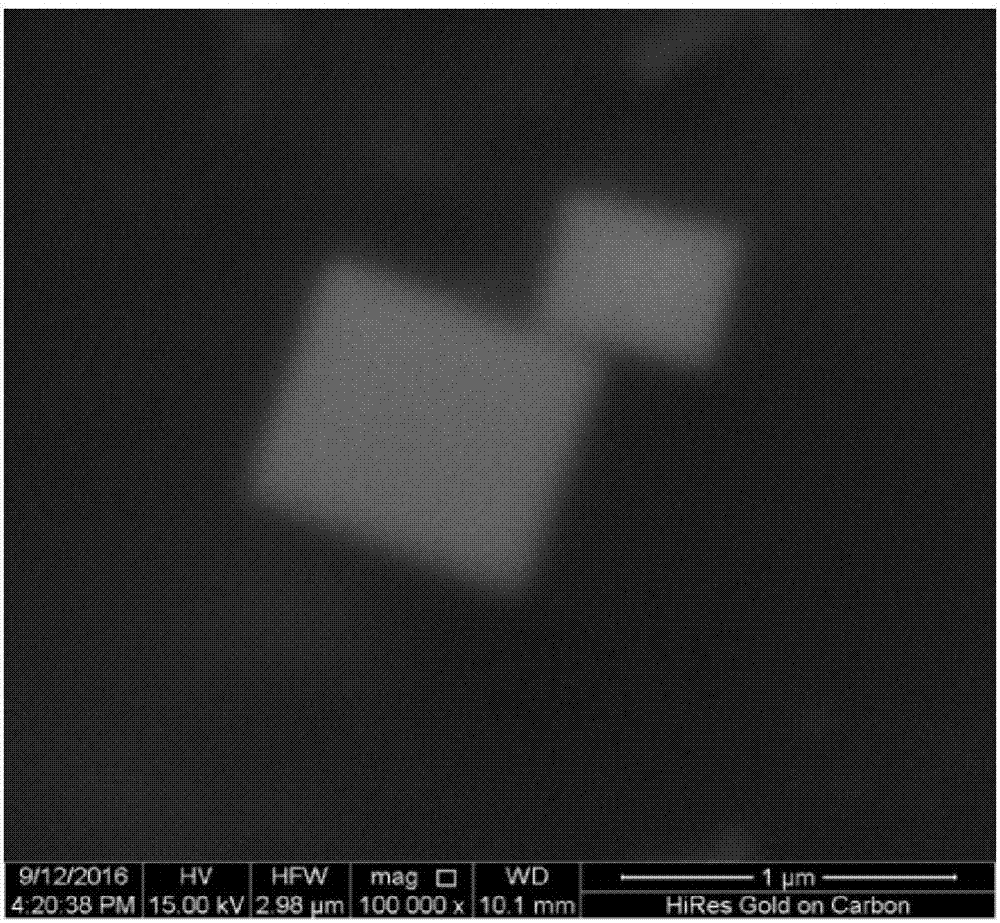

[0035] (4) Take 1mL of the precursor solution and drop it into 10mL of n-hexane at a rate of 0.1ml / s. After stirring at a constant speed, the solution is gradually heated to 50°C and kept at a constant temperature to evaporate for 5 hours. An orange-red color can be observed at the bottom of the solution. Crystals precipitated;

[0036] (5) After the sol...

Embodiment 2

[0038] Use detergent, deionized water, alcohol, acetone, and isopropanol to ultrasonically clean the substrate material in sequence for 5 minutes each time.

[0039] (1) Dissolve the prepared large-size lead cesium halide perovskite crystals in an organic solvent, and stir magnetically until they are completely dissolved, with a concentration of 0.1 mol / L;

[0040] (2) Stir the above solution for 24 hours at 50°C and protected from light to obtain a large-size lead cesium halide perovskite crystal solution;

[0041] (3) Ultrasonic cleaning of the substrate material, and then drying with nitrogen;

[0042] (4) Put the thoroughly dried material in an ultraviolet ozone cleaner for 10 minutes;

[0043] (5) Spread 50 μL of large-size lead cesium halide perovskite crystal solution on the bottom surface of the substrate material, spin coating for 5 seconds, and spin coating at a speed of 3000 revolutions per second;

[0044] (6) The spin-coated material is heated at 50° C. for 100 minutes, and ...

Embodiment 3

[0046] Use detergent, deionized water, alcohol, acetone, and isopropanol to ultrasonically clean the substrate material in sequence for 15 minutes each time.

[0047] (1) Dissolve the prepared large-size lead cesium halide perovskite crystals in an organic solvent, and stir magnetically until they are completely dissolved, with a solubility of 5mol / L;

[0048] (2) Stir the above solution for 2 hours at 100°C and protected from light to obtain a large-size lead cesium halide perovskite crystal solution;

[0049] (3) Ultrasonic cleaning of the substrate material, and then drying with nitrogen;

[0050] (4) Put the thoroughly dried material in an ultraviolet ozone cleaner for 60 minutes;

[0051] (5) Spread 150μL of large-size lead cesium halide perovskite crystal solution on the bottom surface of the substrate material, spin-coating for 50s, and spin-coating at a speed of 3000 rpm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com