Silicon dioxide nanofiber membrane, and preparation method and application thereof

A technology of nanofiber membrane and silica, which is applied in fiber treatment, DNA preparation, spinning solution preparation, etc. It can solve the problems of small specific surface area of silica gel membrane, unfavorable large-scale production, complex process conditions, etc., and achieve surface energy and The effect of high surface activity, small thickness and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] According to a preferred embodiment of the present invention, the density of the silica nanofiber membrane is 1-4kg / m 3 , preferably 1.2-2kg / m 3 .

[0032] In the present invention, the density of the silica nanofiber membrane refers to the measured mass per unit volume at room temperature.

[0033] According to a preferred embodiment of the present invention, the thickness of the silica nanofiber membrane is 25-55 μm, preferably 30-50 μm.

[0034] In the present invention, the thickness of the silica nanofiber film is measured by a spiral micrometer.

[0035] According to a preferred embodiment of the present invention, the silica nanofiber membrane is prepared by electrospinning technology using nano-silicon dioxide as a silicon source.

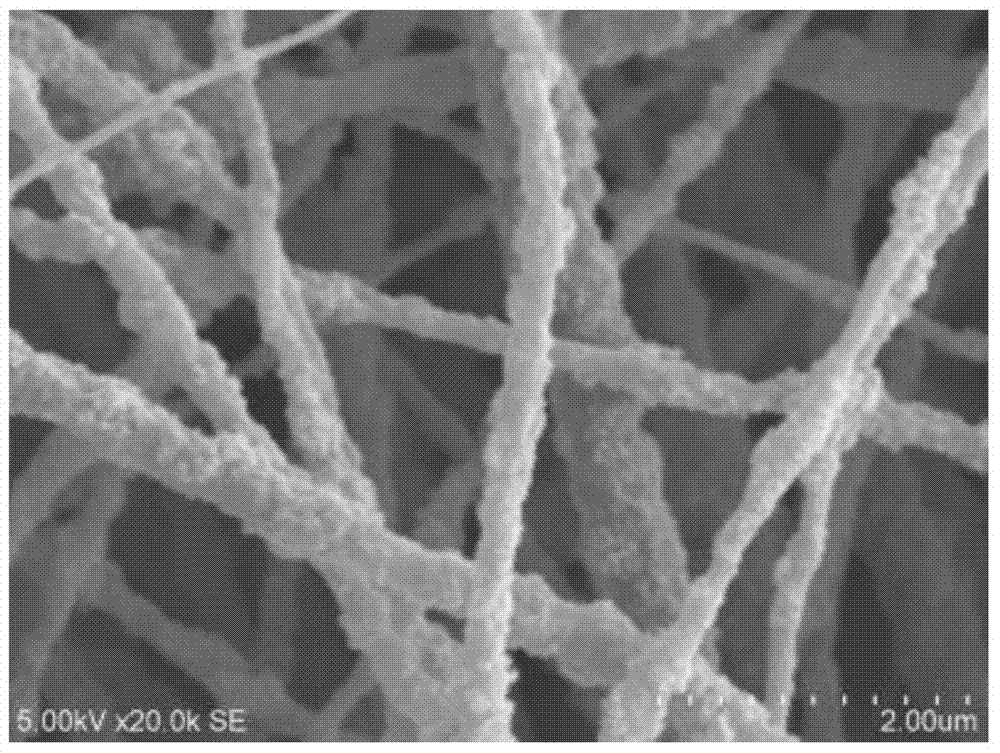

[0036] According to a preferred embodiment of the present invention, the average particle diameter of the nano silicon dioxide is 20-120 nm, preferably 20-50 nm. Adopting this preferred average particle diameter can make the fibe...

Embodiment 1

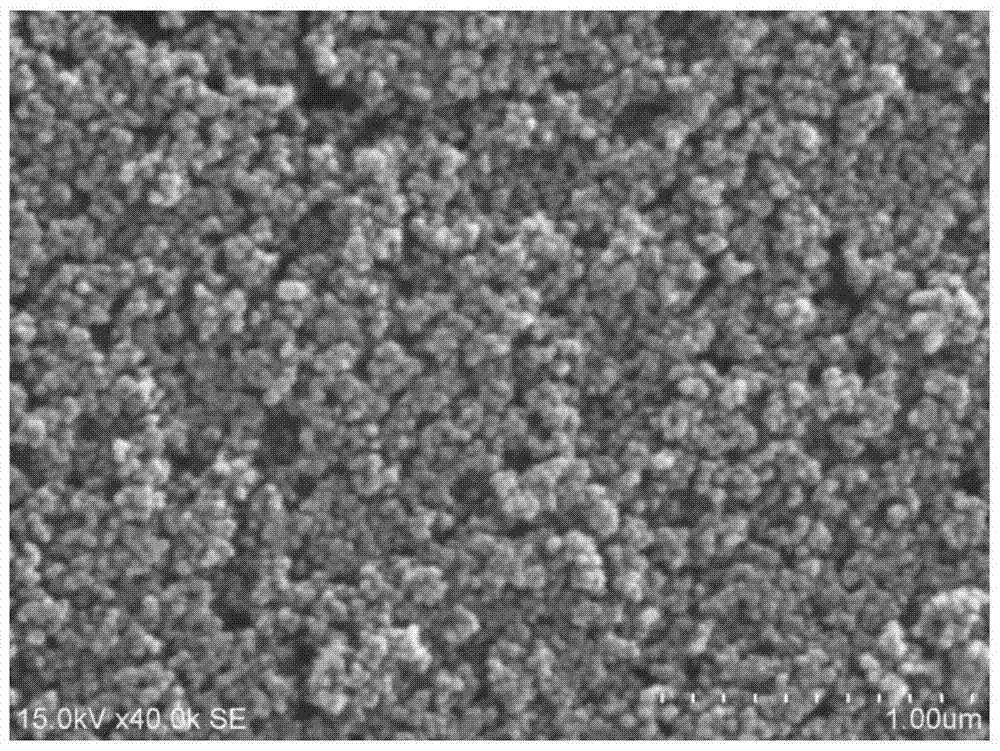

[0073] (1) Weigh 5g of silica nanospheres (with an average particle size of 40nm) and dissolve them in 35g of N,N-dimethylformamide, then add 0.8g of polyethylene glycol 400 (Sinopharm) dropwise, stir and use Ultrasonic the cell disruptor for 2 hours, put it into a grinding disperser, grind and disperse for 8 hours to obtain a nano-silica dispersion, and the SEM image of the nano-silica dispersion is as follows figure 1 As shown, it can be seen from the figure that the nano-silica dispersion is evenly dispersed;

[0074] (2) Weigh 10g of polyacrylonitrile (Bailingwei Technology Co., Ltd.) and dissolve it in 49.2g of N,N-dimethylformamide, and stir it ultrasonically to obtain a polymer solution;

[0075] (3) Pour the nano silicon dioxide dispersion described in step (1) into the polymer solution described in step (2), and stir to obtain a spinning solution, the viscosity of which is 1400cP;

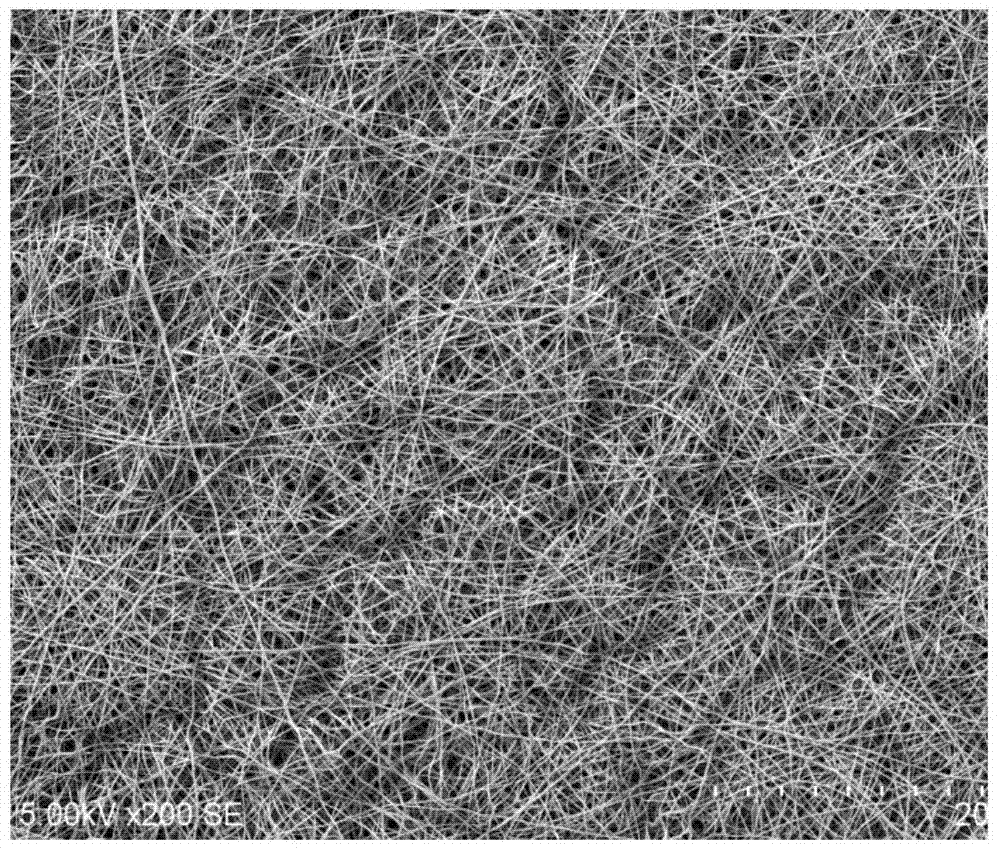

[0076] (4) Utilize electrospinning technology to process the spinning solution descri...

Embodiment 2

[0086] (1) Weigh 3g of silica nanowires (average particle size 20nm) and dissolve them in 20g of dimethyl sulfoxide, then add 0.5g of carboxymethyl cellulose (C104984, Aladdin) dropwise, stir and use cell breaker Ultrasonic instrument for 2 hours, put into a grinding disperser to grind and disperse for 8 hours to obtain a nano-silica dispersion;

[0087] (2) Weigh 7g of polylactic acid (2003D, Nature Works, USA) and dissolve it in 69.5g of N,N-dimethylformamide, and stir it ultrasonically to obtain a polymer solution;

[0088] (3) Pour the nano silicon dioxide dispersion liquid described in step (1) into the polymer solution described in step (2), and stir to obtain a spinning solution, the viscosity of the spinning solution is 800cP;

[0089] (4) Utilize electrospinning technology to process the spinning solution described in step (3), extract 15ml spinning solution with a disposable syringe (diameter 2cm), the implementation parameters of electrospinning technology include: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com