A vertical GaN-based semiconductor device and its manufacturing method

A manufacturing method and GaN-based technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as destructive failure of devices, and achieve the effects of reducing device size, good high frequency, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

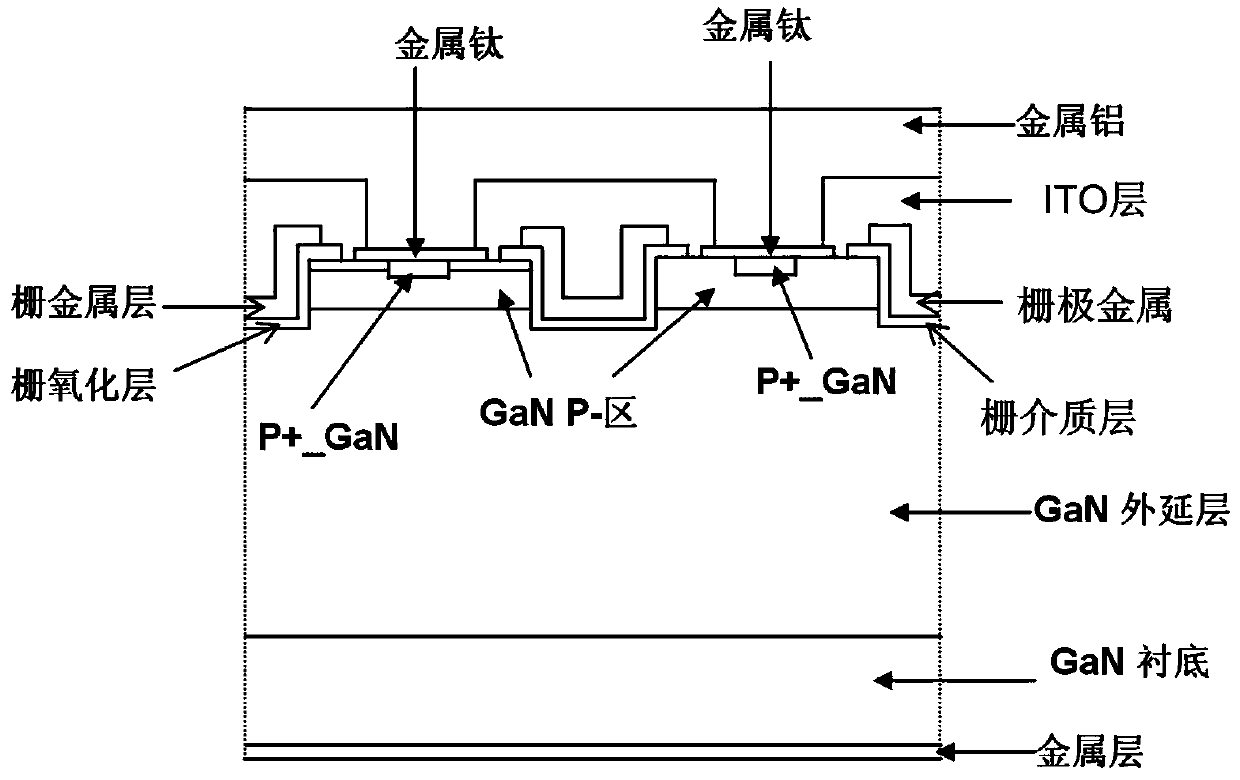

[0057] figure 2 It is a cross-sectional view of the structure of Embodiment 1 of the vertical gallium nitride-based semiconductor device according to the present invention, such as figure 2 As shown, in the vertical GaN-based semiconductor device according to Embodiment 1 of the present invention, the N-type impurity of GaN is implanted by ion implantation, so that the distance between the bottom dielectric layer of the trench and the turning position of the trench is at least 0.1um, The original P-type region becomes an N-type region. When the device is forward-conducting, electrons flow from the source through the inversion layer, the accumulation layer, and the new N-type region at the bottom of the trench, and then vertically pass through the N-type epitaxial extension layer to Bottom drain metal electrode.

Embodiment 2

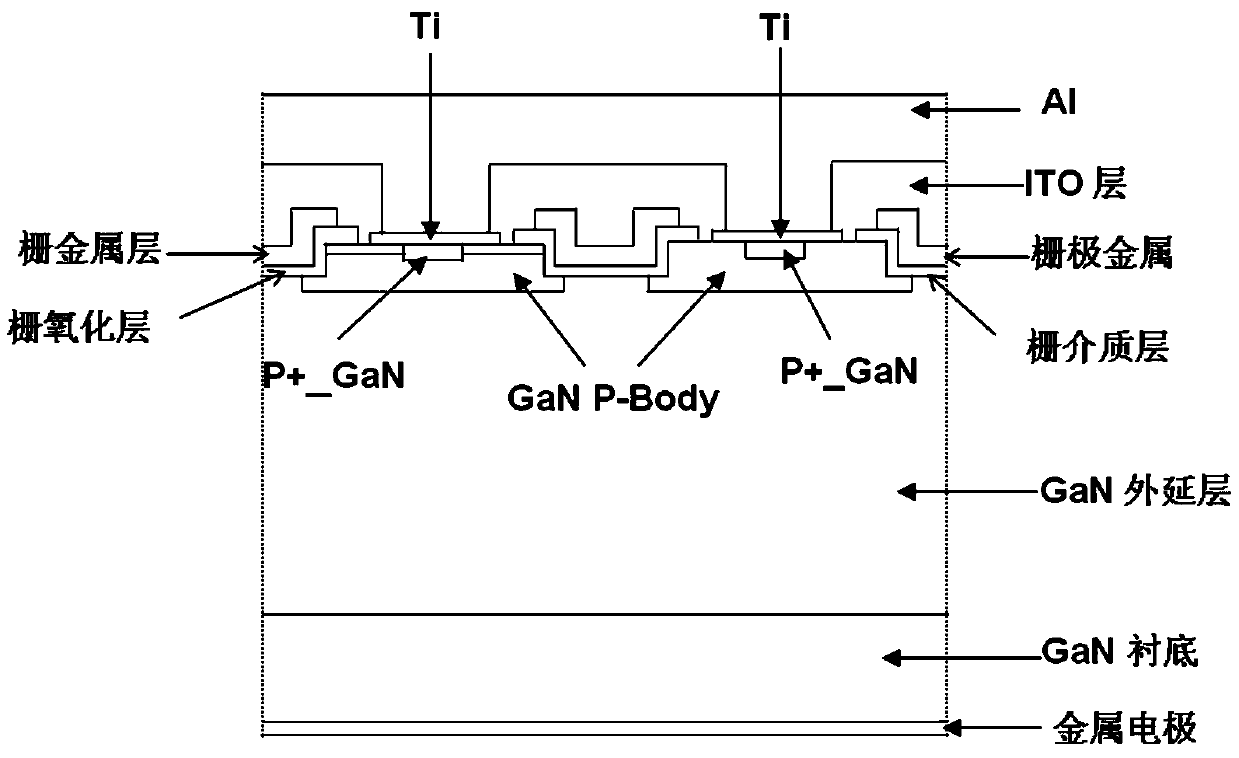

[0059] image 3 It is a cross-sectional view of the structure of Embodiment 2 of the vertical gallium nitride-based semiconductor device according to the present invention, such as image 3 As shown, the structure of the vertical GaN-based semiconductor device according to Embodiment 2 of the present invention is similar to that of Embodiment 1, except that at least a part of the P-type region at the bottom of the trench is not implanted with N-type dopant ions. It remains as a P-type region, and this P-type region can protect the gate dielectric layer at the bottom of the trench when it is reversely biased. The potential of the P-type region at the bottom of the trench is floating and is not connected to the source potential.

Embodiment 3

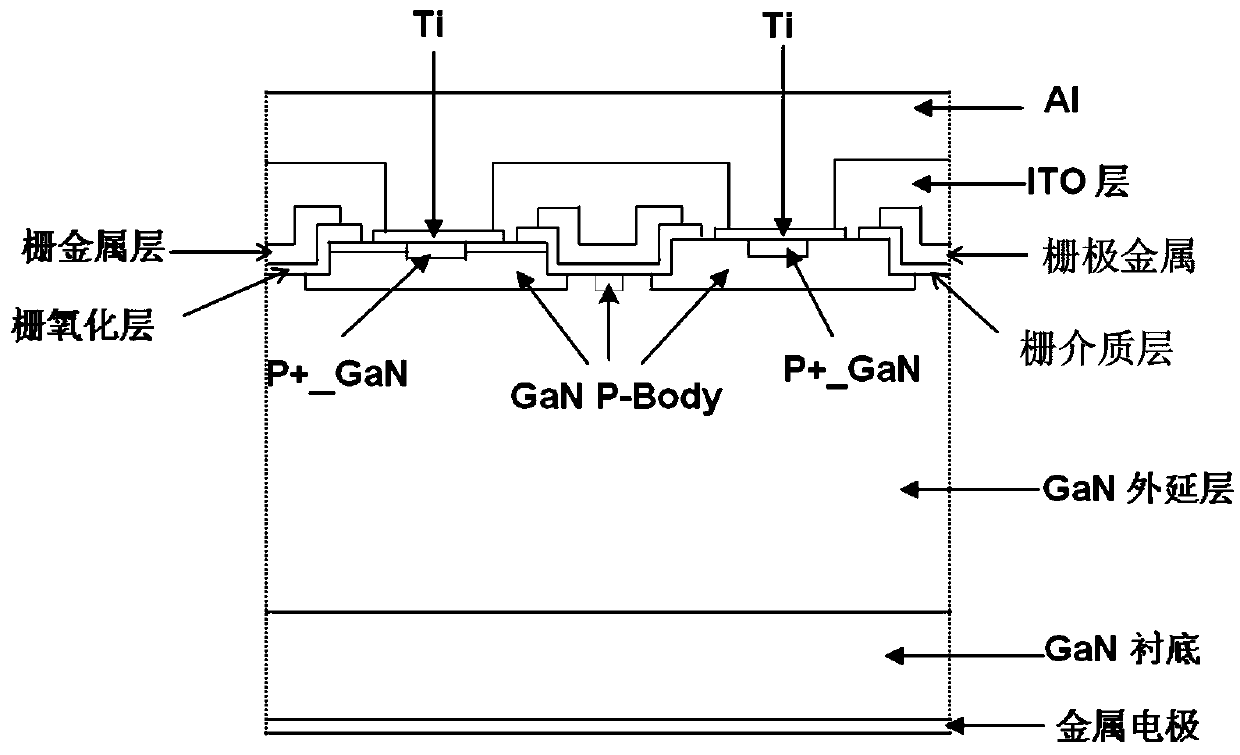

[0061] The structure of the vertical GaN-based semiconductor device according to Embodiment 3 of the present invention is similar to that of Embodiment 2, except that the P-type region at the bottom of the trench is connected to the source potential.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com