Polypeptide natto powder and preparation method thereof

The technology of peptide natto powder and polypeptide powder is applied in the field of polypeptide natto powder and its preparation, which can solve the problems of easy entry of lipids into blood vessel walls, damage to blood vessel walls, easy recurrence, etc., so as to prevent the formation of secondary thrombus, The effect of increasing blood vessel elasticity and enhancing blood vessel toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

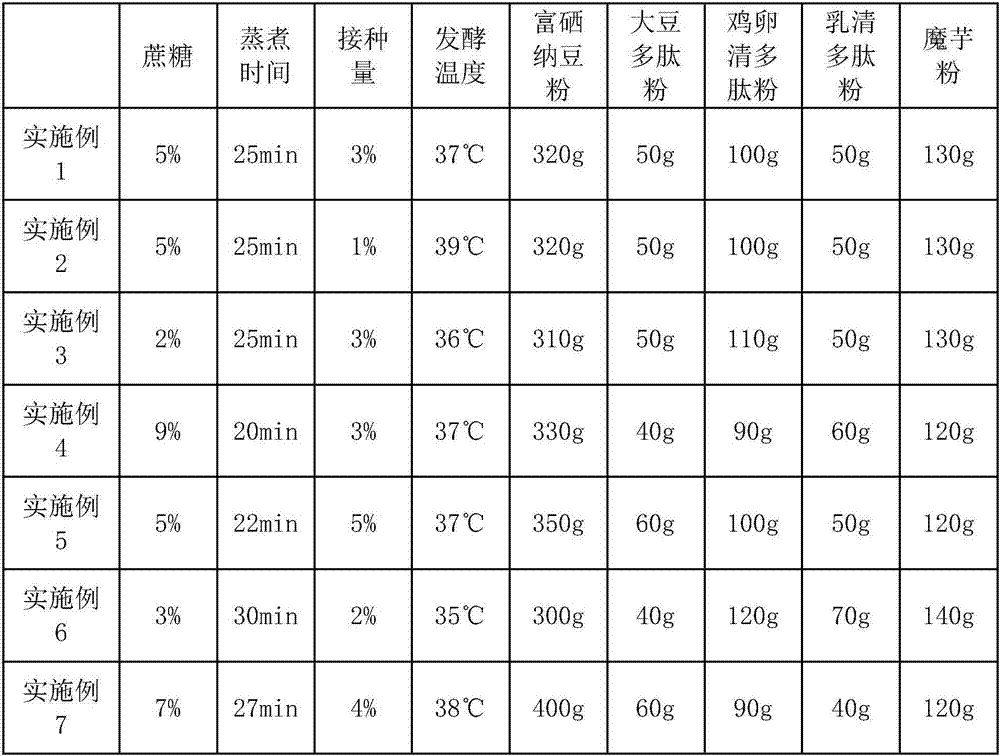

Examples

Embodiment 1

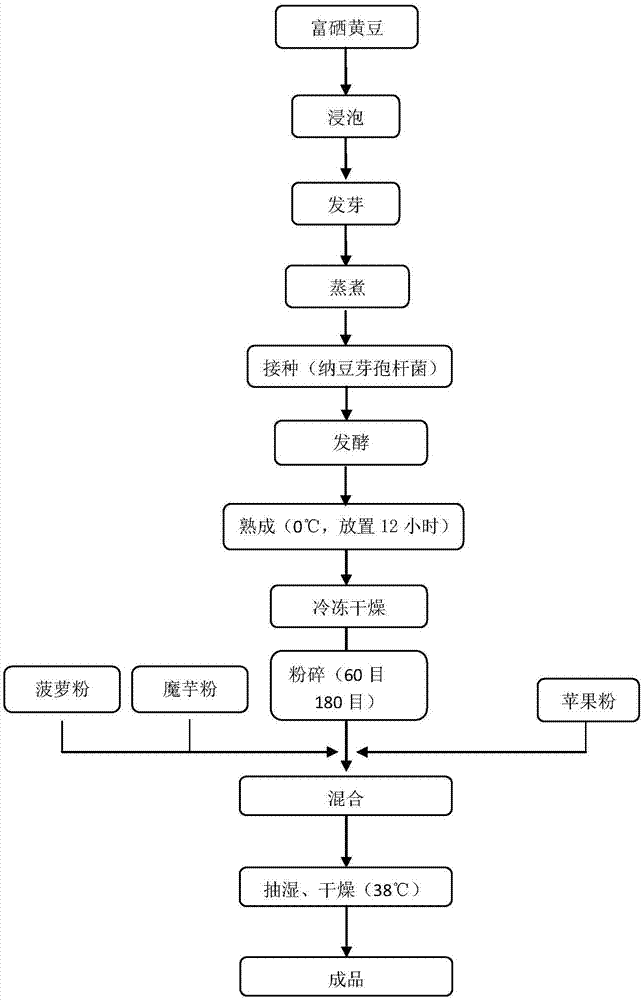

[0035] The production process of polypeptide natto powder is as follows:

[0036] A. Production of natto

[0037] 1. Pretreatment of selenium-enriched soybeans: the raw material selenium-enriched soybeans are manually graded and screened to remove impurities such as stones and sawdust mixed in the selenium-enriched soybeans, and the selenium-enriched soybeans (selenium-enriched soybeans) with full grains, uniform size, and bright color are manually selected. Selenium-enriched soybeans grown in Enshi, Hubei are selected);

[0038] 2. Soaking: wash the pretreated selenium-enriched soybeans and add them to the nutrient solution at a weight ratio of 1:4 for immersion, soak for 20 hours at 7°C, and then rinse with pure water, wherein the nutrient solution includes the following expressed in weight percentages Components: Sodium Selenite 0.02%, Magnesium Sulfate 0.2%, Sodium Chloride 0.2%, Chromium Chloride 0.01%, Purified Water 95.7%;

[0039] 3. Germination: Put the soaked selen...

Embodiment 8

[0050] Embodiment 8: The difference of embodiment 1 is that no sucrose is added in the cooking process.

Embodiment 1 to 8

[0051] The natto sensory properties of embodiment 1 to 8 production:

[0052] For the natto produced by the process of Examples 1-8, a white film is formed on the surface of the fermented natto, which is viscous and long in wire drawing, and the resulting natto is yellowish in color and has a metallic luster. Wherein the natto produced by the production process of Example 1 has the strongest viscosity and the longest wire drawing, and because nattokinase mainly exists in the viscous wire drawing of natto, it can be seen preliminarily from the sensory properties of natto that embodiment 1 The produced natto has a high content of nattokinase.

[0053] Measure the content of bacillus natto and nattokinase in the natto produced by fermenting selenium-enriched soybeans from embodiment 1 to embodiment 8 with colony plate counting method and FU ultraviolet spectrophotometry, as shown in table 2:

[0054] Table 2

[0055]

[0056]

[0057] The authorized announcement number is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com