an anti-co 2 、h 2 s corrosion cementing cement slurry

A cementing cement slurry and cement slurry technology, applied in the direction of wellbore/well components, chemical instruments and methods, drilling compositions, etc., can solve the problems of shortening the life of oil and gas wells, increasing permeability, and reducing compressive strength, etc. problem, to prolong the solidification time, eliminate micro-bubbles, and improve rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Anti-CO 2 H 2 S corrosion cement slurry, the cement slurry consists of water and cement according to the mass ratio (water ash ratio), wherein the cement comes from the following material materials: 100 quality unit G-stage high anti-sulfate oil cement , 12 quality units of fine cement, 1 quality unit of dispersant SXY, 1.2 mass units of dense water BXF-200L, 6 quality units of micro-silicon JM-1, 8 quality units of fly ash , 1.2 quality units of expansion agent M53S, 9 quality units of latex BCT-800L, 1 quality unit of water soluble methyl ether to urea resin, 1.5 quality units of early strength agent CK21, 0.1 mass units Differential Sn-2,0.6 quality units of defoamer D50.

[0016] CO 2 H 2 The method of preparing a water-soluble solid cement slurry is to uniformly mix the water-soluble methylene etherdehyde resin and water, and then make the mixed fluid and the lost water supply agent BXF-200L, latex BCT-800L, and the slower Sn-2 , The defoaming agent D50 is mixed to obt...

Embodiment 2

[0018] Anti-CO 2 H 2 S corrosion cement slurry, the cement slurry consists of water and cement according to the mass ratio (water ash ratio), wherein the cement comes from the following material materials: 100 quality unit G-stage high anti-sulfate oil cement , 15 quality units of fine cement, 1.5 quality unit dispersant SXY, 1.3 quality units of dense water agent BXF-200L, 5 quality units of micro-silicon JM-1, 8 quality units of fly ash , 1.3 quality units of expansion agent M53S, 6 quality units of latex BCT-800L, 1.4 quality units of water-soluble maleic anhydride modified epoxy resin, 2.5 quality units of early strong agent CK21, 0.2 mass units Slim Sn-2,0.7 quality unit of defoamer D50.

[0019] CO 2 H 2 The method of corrosion cement slurry is the same as in Example 1. Code formula 2.

Embodiment 3

[0021] Anti-CO 2 H 2 S corrosion cement slurry, the cement slurry consists of water and cement according to the mass ratio (water ash ratio), wherein the cement comes from the following material materials: 100 quality unit G-stage high anti-sulfate oil cement , 17 quality units of fine cement, 1.8 quality unit dispersant SXY, 1.2 quality units of dispensing agent BXF-200L, seven quality units of micro-silicon JM-1, 6 quality units of fly ash , 1.7 quality units of expansion agent M53S, 7 quality units of latex BCT-800L, 1.3 quality units of water-soluble acrylic modified alkyd resin, 2 quality units of early strength agent CK21, 0.2 mass units The antifoaming agent D50 of the condensant SN-2, 0.7 mass units.

[0022] CO 2 H 2 The method of corrosion cement slurry is the same as in Example 1. Code formula 3.

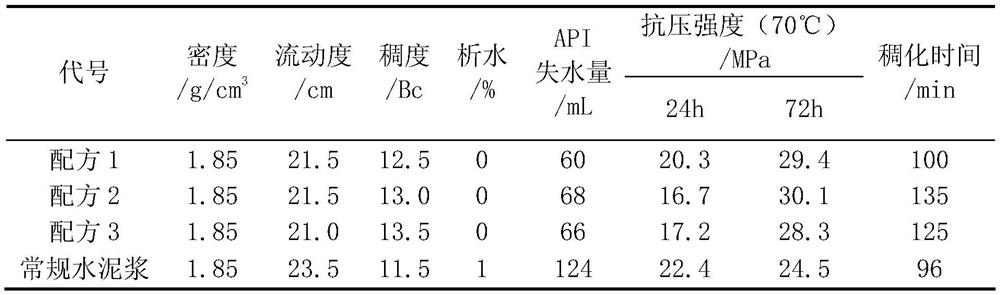

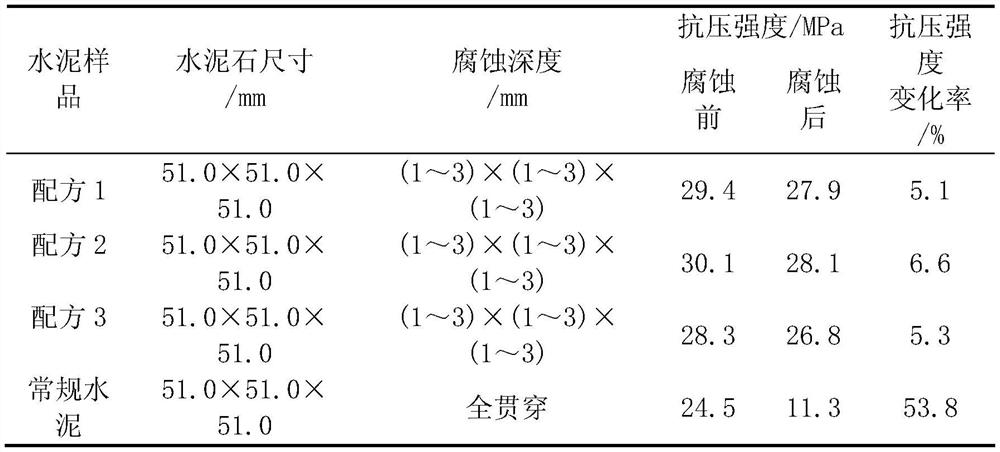

[0023] To study the performance of the invention, the designer will compare the formulation 1, formulation 2, formulation 3 and conventional cement slurry. Correlation proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com