Method for preparing antibacterial and mouldproof ethylene-removing fresh-keeping film for fruits and vegetables

An antibacterial, mildew-proof and fresh-keeping technology for fruits and vegetables, which is applied in the field of fresh-keeping material preparation, can solve the problems of stimulating the physiological activity of fruits and vegetables, spoilage of fruits and vegetables, shortening storage time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

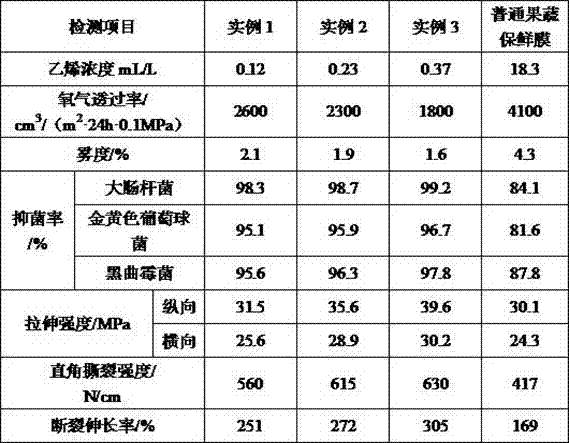

Examples

example 1

[0021] Take 1.2g of cobalt nitrate hexahydrate, 0.9g of cerium nitrate hexahydrate, and 1.4g of tetrabutyl titanate into 50mL of deionized water, stir at 300r / min for 20min, then add 2g of polyethyleneimine and 2g of ethylenediaminetetraacetic acid, Continue to stir for 30 minutes, then transfer to a rotary evaporator, and evaporate to dryness at 70°C to obtain a polymer precursor, which is loaded into a muffle furnace and heated to 350°C at a heating rate of 2°C / min , keep the temperature and calcined for 1h, then heat up to 450°C at a heating rate of 1°C / min and keep the temperature for calcination for 1h, after naturally cooling to room temperature, transfer the calcined product to a ball mill, ball mill at 300r / min for 1h, and pass through a 300-mesh sieve to obtain Composite metal oxide, then weigh 2g chitosan, add 80mL mass fraction of 2% acetic acid solution, stir at 300r / min until chitosan is completely dissolved, then add 3g naringin, 0.04g horseradish peroxidase , co...

example 2

[0023] Take 1.5g of cobalt nitrate hexahydrate, 1.1g of cerium nitrate hexahydrate, and 1.7g of tetrabutyl titanate into 55mL of deionized water, stir at 350r / min for 25min, then add 2g of polyethyleneimine, 2g of ethylenediaminetetraacetic acid, Continue to stir for 40 minutes, then transfer to a rotary evaporator, and evaporate to dryness at 75°C to obtain a polymer precursor. Put the polymer precursor into a muffle furnace and heat it to 375°C at a heating rate of 2°C / min. , keep the temperature and calcined for 1h, then heat up to 475°C at a heating rate of 1°C / min and keep the temperature for calcination for 1h, after naturally cooling to room temperature, transfer the calcined product to a ball mill, ball mill at 350r / min for 1h, and pass through a 300-mesh sieve to obtain Composite metal oxide, then weigh 2g chitosan, add 90mL mass fraction of 2% acetic acid solution, stir at 350r / min until chitosan is completely dissolved, then add 3g naringin, 0.05g horseradish peroxid...

example 3

[0025]Take 1.8g cobalt nitrate hexahydrate, 1.3g cerium nitrate hexahydrate, and 2.0g tetrabutyl titanate into 60mL deionized water, stir at 400r / min for 30min, then add 3g polyethyleneimine, 3g ethylenediaminetetraacetic acid, Continue to stir for 50 minutes, then transfer to a rotary evaporator, and evaporate to dryness at 80°C to obtain a polymer precursor. Put the polymer precursor into a muffle furnace and heat it to 400°C at a heating rate of 3°C / min. , keep the temperature for calcination for 2 hours, then heat at 2°C / min to 500°C and keep the temperature for calcination for 2h, after naturally cooling to room temperature, transfer the calcined product to a ball mill, ball mill at 400r / min for 2h, and pass through a 300-mesh sieve to obtain Composite metal oxide, then weigh 3g chitosan, add 100mL mass fraction of 2% acetic acid solution, stir at 400r / min until chitosan is completely dissolved, then add 4g naringin, 0.06g horseradish peroxidase , continue to stir for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com