Integrated advanced-treatment process for nitration and dioxin elimination of incineration tail gas

A dioxin removal and advanced treatment technology, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as unstable operation, high cost, and low efficiency of dioxin treatment technology, and achieve operational stability High, easy to operate, the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

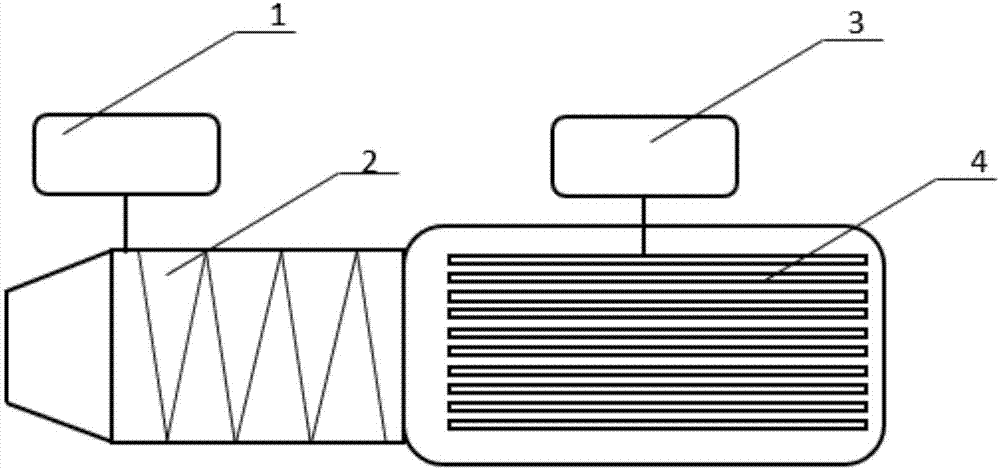

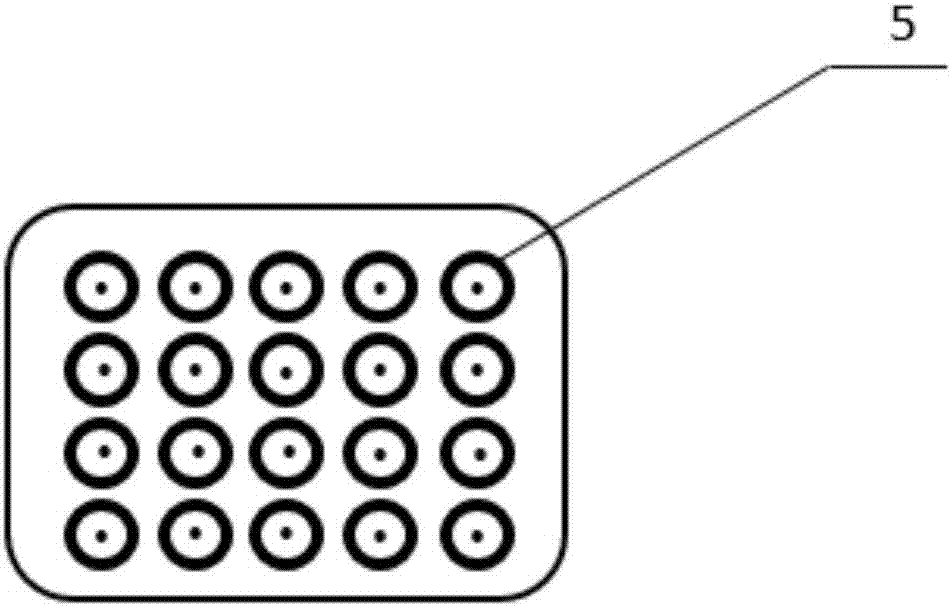

[0032] The photocatalyst supported on the inner wall of the low-voltage electrode of the high-energy discharge reactor device is TiO 2 / Ni, the diameter of titanium wire at the high-voltage end is 0.2mm, the frequency is 500Hz, the power is 3Kw; the amount of mixed ozone is 10% of the total amount of exhaust gas (V / V), and the spray density of the scrubber is 2m 3 / (m 2 , h), using 10 wt% NaOH solution.

[0033] Treated paint fog nitrogen oxides 90mg / m 3 , Dioxin 0.0252ng / m3, the discharge complies with the "Pollution Control Standards for Hazardous Waste Incineration" (GB18484-2014).

Embodiment 2

[0035] The photocatalyst supported on the inner wall of the low-voltage electrode of the high-energy discharge reactor device is TiO 2 / Pt, the diameter of titanium wire at the high-voltage end is 0.4mm, the frequency is 1000Hz, the power is 1Kw; the amount of mixed ozone is 5% of the total amount of exhaust gas (V / V), and the spray density of the scrubber is 4m 3 / (m 2 , h), using 8wt% Ca(OH) 2 solution.

[0036] Treated paint fog nitrogen oxides 110mg / m 3 , Dioxin 0.0312ng / m 3 , and the discharge complies with the Pollution Control Standard for Hazardous Waste Incineration (GB18484-2014).

Embodiment 3

[0038] The photocatalyst loaded on the inner wall of the low-voltage electrode of the high-energy discharge reactor device is SnO / Ni, the diameter of the titanium wire at the high-voltage end is 0.1mm, the frequency is 600Hz, and the power is 2Kw; the amount of mixed ozone is 8% (V / V) of the total amount of exhaust gas, The spray density of the scrubber is 3m 3 / (m 2 , h), using 12 wt% KOH solution.

[0039] Treated nitrogen oxides 100mg / m 3 , Dioxin 0.0282ng / m 3 , and the discharge complies with the Pollution Control Standard for Hazardous Waste Incineration (GB18484-2014).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com