Special compound admixture for marine concrete

A composite admixture and marine concrete technology, which is applied in the field of marine engineering, can solve the problems of difficulty in the use and maintenance of concrete engineering, and the inability to ensure the safety, durability, and long-term effect of concrete structures, so as to achieve excellent later strength, increase density, reduce The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

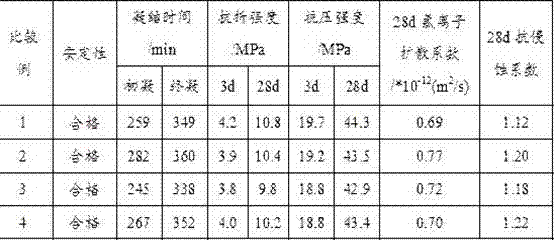

Examples

Embodiment 1

[0015] A special composite admixture for marine concrete, which is composed of the following raw materials in weight percentage: 11% high-grade material, 32% ground quartz sand, 12% waste silicon powder, 22% chloride ion adsorbent, and 6% sodium nitrite %, sodium sulfate 4%, calcium sulfoaluminate 9%, polycarboxylate superplasticizer 4%.

[0016] The metakaolin is obtained by calcining kaolin at a high temperature of 600°C-900°C, ground to a fineness of 1250 mesh, an average particle size of 12μm, and a specific surface area of 450m 2 / Kg.

[0017] The fineness of the quartz sand is 1250 mesh, the average particle size is 12 μm, and the specific surface area is 440m 2 / Kg, SiO 2 The content is greater than 90%.

[0018] The waste silicon powder is an industrial by-product of producing polycrystalline silicon wafers, with a fineness of 6000 mesh, an average particle size of 2.5 μm, and a specific surface area of 1000 m 2 / Kg, SiO 2 Content > 95%.

[0019] The chlorine...

Embodiment 2

[0021] A special composite admixture for marine concrete, which is composed of the following raw materials in weight percentage: 15% high-grade soil, 26% ground quartz sand, 20% waste silicon powder, 18% chloride ion adsorbent, 5% sodium nitrite %, sodium sulfate 5%, calcium sulfoaluminate 7%, polycarboxylate superplasticizer 4%.

[0022] The metakaolin is obtained by calcining kaolin at a high temperature of 600°C-900°C, and is ground to a fineness of 2000 mesh, with an average particle size of 7.5μm and a specific surface area of 600m 2 / Kg.

[0023] The fineness of the ground quartz sand is 2000 mesh, the average particle size is 7.5 μm, and the specific surface area is 510m 2 / Kg, SiO 2 The content is greater than 90%.

[0024] The waste silicon powder is an industrial by-product of the production of polycrystalline silicon wafers, with a fineness of 10,000 mesh, an average particle size of 1.5 μm, and a specific surface area of 1800 m 2 / Kg, SiO 2 Content > 95%. ...

Embodiment 3

[0028] A special composite admixture for marine concrete, which is composed of the following raw materials in weight percentage: 20% of high-grade material, 21% of ground quartz sand, 26% of waste silicon powder, 15% of chloride ion adsorbent, and 5% of sodium nitrite %, sodium sulfate 4%, calcium sulfoaluminate 6%, polycarboxylate superplasticizer 3%.

[0029] The metakaolin is obtained by calcining kaolin at a high temperature of 600°C-900°C, and is ground to a fineness of 3000 mesh, with an average particle size of 5 μm and a specific surface area of 750m 2 / Kg.

[0030] The fineness of the ground quartz sand is 3000 mesh, the average particle size is 5 μm, and the specific surface area is 628m 2 / Kg, SiO 2 The content is greater than 90%.

[0031] The waste silicon powder is an industrial by-product of the production of polycrystalline silicon wafers, with a fineness of 20,000 mesh, an average particle size of 0.75 μm, and a specific surface area of 2,300 m 2 / Kg, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com