Method for growing gallium nitride material on sapphire substrate, gallium nitride material and application thereof

A sapphire substrate and gallium nitride technology, which is applied in lasers, electrical components, circuits, etc., can solve the problems that the quality of gallium nitride crystals needs to be further improved, and achieve good crystal quality, promote desorption, and improve crystal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

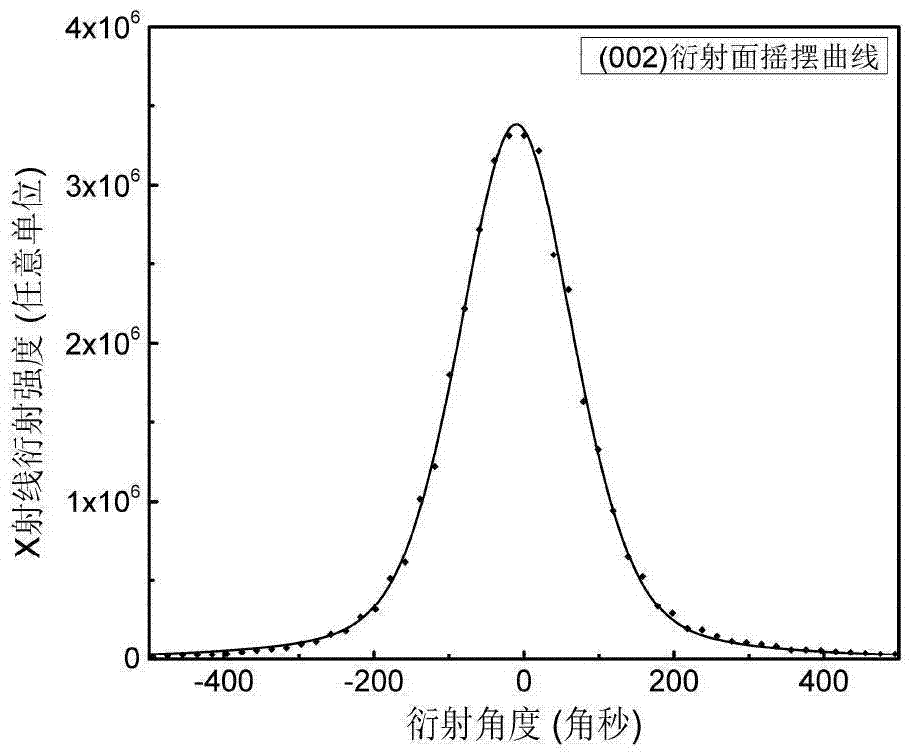

[0083] (1) Place the flat sapphire sheet as the substrate used for growth on the graphite tray in the reaction chamber of metal organic chemical vapor deposition (MOCVD), in H 2 Under the condition of flowing atmosphere, raise the temperature of the graphite tray to 1000°C; under the condition of 1000°C, pass trimethylgallium (TMGa) into the reaction chamber and keep it warm for 5 minutes to complete the pretreatment of the sapphire surface;

[0084] Typically, for the MOCVD reaction chamber whose graphite tray diameter is 540mm, the flow rate of the trimethylgallium brought into the reaction chamber by the carrier gas is 300 sccm (standard milliliters per minute), and the temperature of the corresponding trimethylgallium liquid source bottle here The temperature is 5°C, and the source bottle pressure is 1300mbar.

[0085] (2) Stop feeding trimethylgallium into the reaction chamber, and reduce the temperature of the graphite tray to 550°C, then pass trimethylgallium and ammoni...

Embodiment 2

[0092] Except step (1), other preparation conditions and method are identical with embodiment 1.

[0093] Present embodiment (1) step is specifically as follows:

[0094] Place the flat sapphire sheet used as the growth substrate on the graphite tray in the reaction chamber of MOCVD, under N 2 Raise the temperature of the graphite tray to 800°C under a flowing atmosphere; under the condition of 800°C, pass trimethylgallium (TMGa) into the reaction chamber and keep it warm for 10 minutes to complete the pretreatment of the sapphire surface;

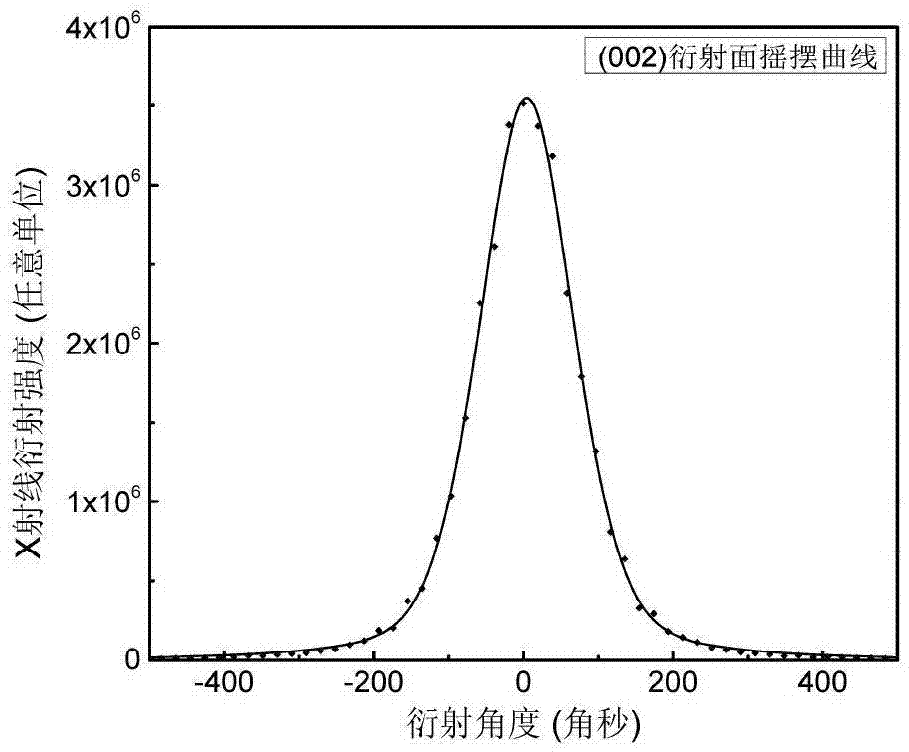

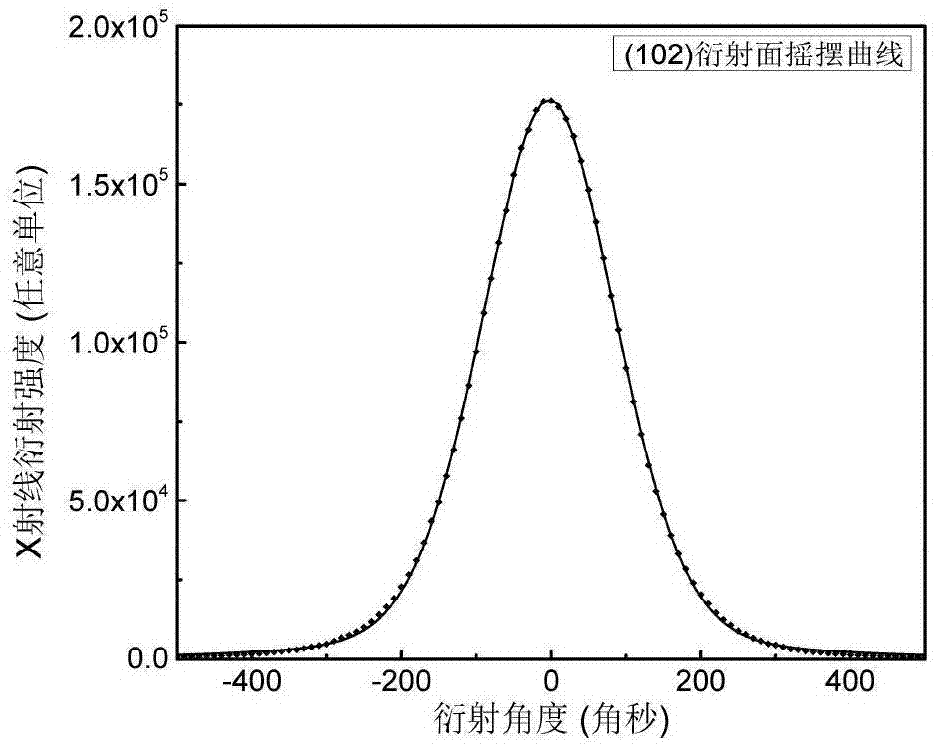

[0095] The crystal quality of the gallium nitride thin film material obtained by growth is measured by X-ray diffraction. The value of the half maximum width of the (002) diffraction surface is 150 ± 5 arc seconds, and the value of the half maximum width of the (102) diffraction surface is 210 ± 5 angles. Second.

Embodiment 3

[0097] Except step (1), other preparation conditions and method are identical with embodiment 1.

[0098] Present embodiment (1) step is specifically as follows:

[0099] Place the flat sapphire sheet used as the growth substrate on the graphite tray in the reaction chamber of MOCVD, under H 2 Under the condition of flowing atmosphere, raise the temperature of the graphite tray to 1200°C; under the condition of 1200°C, pass trimethylgallium (TMGa) into the reaction chamber and keep it warm for 2 minutes to complete the pretreatment of the sapphire surface;

[0100] The crystal quality of the gallium nitride thin film material obtained by growth is measured by X-ray diffraction. The value of the half maximum width of the (002) diffraction surface is 150 ± 5 arc seconds, and the value of the half maximum width of the (102) diffraction surface is 210 ± 5 angles. Second.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com