Preparation method for reaction type nitrogen-phosphorus flame retardant

A nitrogen-phosphorus flame retardant and reactive technology, which is applied in the field of preparation of reactive nitrogen-phosphorus flame retardants, can solve problems such as the influence of material processing properties on physical and mechanical properties, achieve low processing performance and physical and mechanical properties, and avoid migration , the effect of reducing the emission of toxic and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

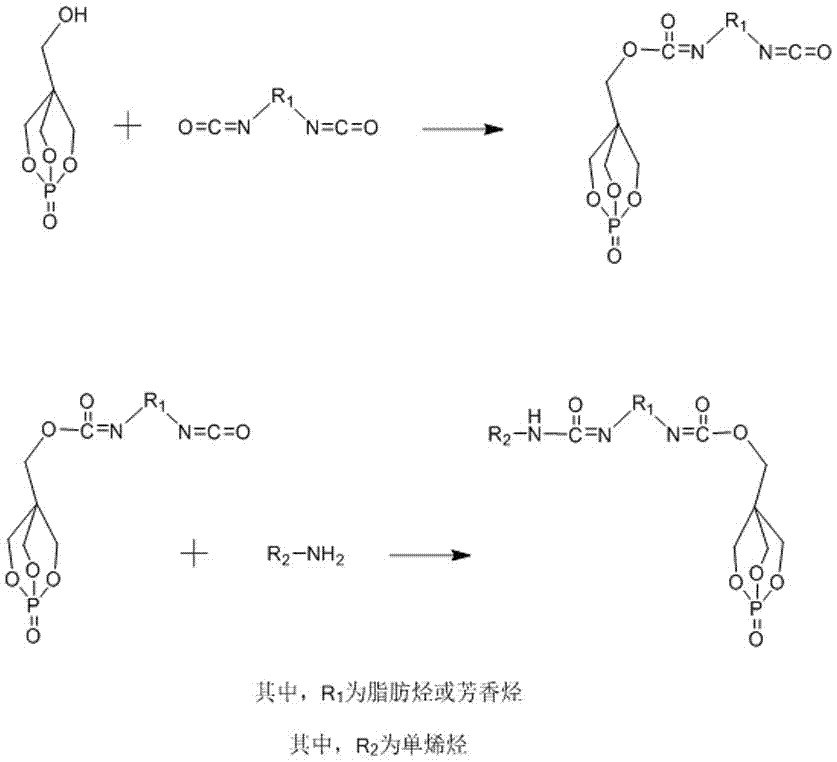

[0017] refer to figure 1 , the present specific embodiment adopts following technical scheme: a kind of preparation method of reactive nitrogen phosphorus flame retardant, comprises the following steps: 1, the purification of pentaerythritol phosphate (PEPA): get 50-300gPEPA, add 200-500ml dehydrated alcohol In 80-230r / min rotation speed, heated to boiling at 70-80°C, filtered while hot, cooled, recrystallized, and vacuum-dried at 60-120°C for 25-72h to obtain purified PEPA.

[0018] 2. Activate PEPA with isocyanic acid: Take 100-300ml of anhydrous solvent in a three-necked flask, add 10-200g of diisocyanate, nitrogen protection, slowly add 10-200g of PEPA, in a 40-120℃ water bath, 80- React at 230r / min for 4-8h to obtain isocyanic acid-activated PEPA.

[0019] 3. Preparation of reactive nitrogen-phosphorus flame retardant: Weigh unsaturated fatty amine (alcohol) and add it dropwise to step 2 isocyanic acid activated PEPA. The reaction is continued for 4-10 hours, the reacti...

Embodiment 1

[0023] Example 1: Step 1. Purification of Pentaerythritol Phosphate (PEPA)

[0024] Pour 300ml of absolute ethanol into a 500ml three-neck flask, add 150g of PEPA, stir electromagnetically at a speed of 150r / min, heat the water bath until the solution boils, filter while it is hot, cool, recrystallize, and vacuum dry at 80°C for 30h to obtain purified PEPA.

[0025] Step 2. Covalently bonded isocyanate to activate PEPA

[0026] Take 150ml of anhydrous xylene in a 250ml three-neck flask, add 17.415g of toluene diisocyanate (TDI), 180r / min electromagnetic stirring, nitrogen protection, take 18.0g of PEPA and add it in 9 times, each interval of 10min, in a 70℃ water bath After reacting for 6 hours, the isocyanate-activated PEPA reaction solution was obtained for use.

[0027] Step 3. Preparation of Reactive Nitrogen-Phosphorus Flame Retardant

[0028] Weigh 5.8g of 2-propen-1-amine, and slowly add it dropwise to the activated PEPA solution obtained in step 2. The system contin...

Embodiment 2

[0031] Embodiment 2: the formula of natural rubber, by weight: 100 parts of natural rubber, 6 parts of zinc oxide, 2 parts of stearic acid, 0.5 part of antioxidant 4010NA, 3 parts of paraffin, 3 parts of sulfur, accelerator CZ0. 5 parts, accelerator DM0.8 parts, carbon black (N330) 20 parts, expandable graphite 10 parts, reactive nitrogen phosphorus flame retardant 30 parts. After plasticizing, kneading, calendering, extruding and vulcanization, flame-retardant natural rubber is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com