Preparation method of polycrystal cubic boron nitride sintering body material

A polycrystalline cubic boron nitride technology, which is applied in the field of preparation of polycrystalline cubic boron nitride (PcBN) sintered body materials, can solve the problem of insufficient consideration of polycrystalline cubic boron nitride sintered body mixture, preparation difficulty and cost, and Quality control and other issues to achieve the effect of improving uniformity and yield, improving quality and low thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

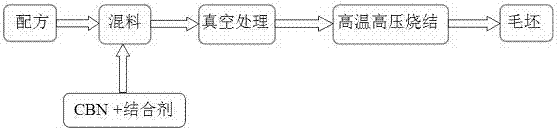

[0036] The preparation method of the polycrystalline cubic boron nitride sintered body material in this embodiment is as follows:

[0037] Select the mass fraction ratio of binder metal powder and titanium carbide, tungsten carbide, and titanium nitride to the raw material powder to be 40%, wherein the mass ratio of carbide or nitride is 9.5:1, and the content of cobalt powder is not greater than the total mass fraction 4%, the content of aluminum powder is not more than 6% of the total mass fraction, the particle size of the metal powder is 0.1-3 microns; the cubic boron nitride powder with a particle size of 35 microns is crushed into particles with a particle size of 0-7 microns as the raw material , the mass fraction ratio of cubic boron nitride micropowder to raw material micropowder is 60%. The above-mentioned raw material powders are respectively subjected to chemical acid-base treatment and physical vacuum treatment to remove oxygen, water and other impurities from the...

Embodiment 2

[0042] The preparation method of the polycrystalline cubic boron nitride sintered body material in this embodiment is as follows:

[0043] Select binder metal powder and tungsten carbide, titanium carbide, titanium carbide nitrogen to account for 20% of the mass fraction ratio of the raw material powder, wherein the mass ratio of tungsten carbide, titanium carbide, titanium carbide nitrogen carbide is 2:2:1, the titanium powder The content is not more than 3% of the total mass, the content of aluminum powder is not more than 7% of the total mass fraction, the particle size of the metal powder is 0.1-3.5 microns; the cubic boron nitride powder with a particle size of 35 microns is crushed into a particle size of 0-7 Micron particles are used as the raw material, and the mass fraction ratio of cubic boron nitride powder to the raw material powder is 80%. Oxygen, water and other impurities in the raw materials are removed through chemical acid-base treatment and physical vacuum t...

Embodiment 3

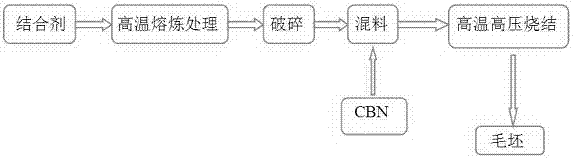

[0048] The preparation method of the polycrystalline cubic boron nitride sintered body material in this embodiment is as follows:

[0049] (1) The raw materials of cubic boron nitride micropowder, aluminum powder, silicon nitride and titanium carbide are respectively subjected to chemical acid-base treatment and physical vacuum treatment to remove oxygen, water and impurities in the raw materials;

[0050] (2) Mix the aluminum powder, silicon nitride and titanium carbide processed in step (1) and melt at a high temperature of 1000°C, then crush and classify the smelted product to obtain a composite binder; in the composite binder, silicon nitride and The mass fraction of titanium carbide is 10%, and the mass ratio of silicon nitride to titanium carbide is 5:1;

[0051] (3) Mix the cubic boron nitride micropowder treated in step (1) with the composite binder obtained in step (2) and then ball mill. The mass ratio of cubic boron nitride micropowder to composite binder is 5:5. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com