Colored curable resin composition

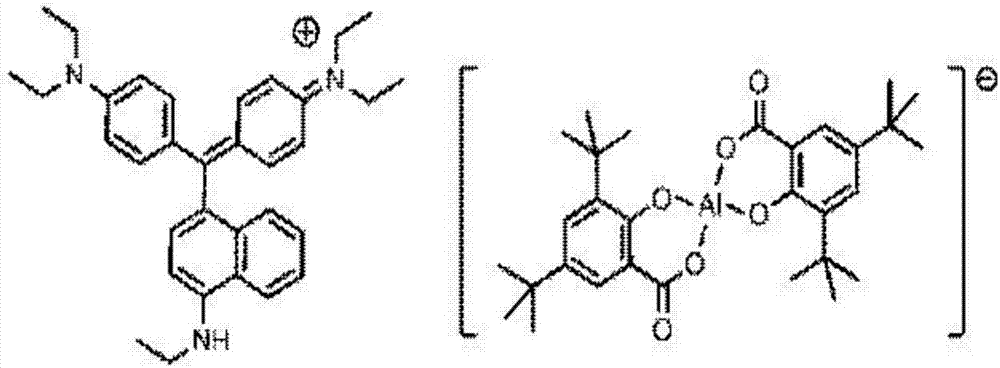

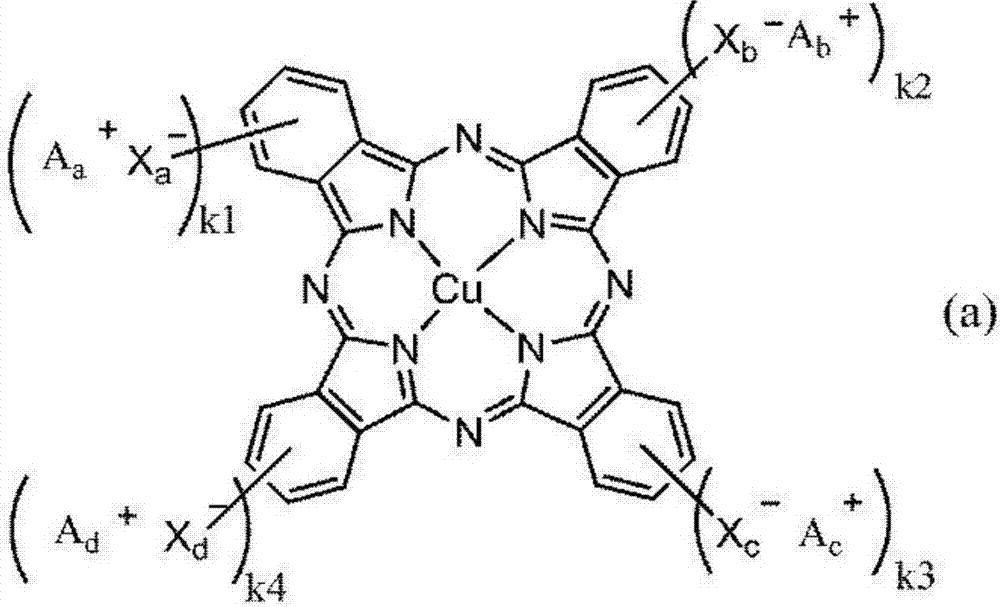

A technology of curable resins and compositions, applied in chemical instruments and methods, porphine/acrphine, anthracene dyes, etc., can solve the problems of reduced heat resistance and chemical resistance, and achieve good heat resistance, The effect of good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0486] Hereinafter, the colored curable resin composition of the present invention will be described in more detail by way of examples. Unless otherwise specified, "%" and "part" in an example are mass % and a mass part.

[0487] In the following synthesis examples, compounds were identified by mass spectrometry (LC; Agilent 1200 type, MASS; Agilent LC / MSD type) or elemental analysis (VARIO-EL; (Elementer Co., Ltd.)).

Synthetic example 1

[0489] In the reactor, 32.3 parts of pararosaniline hydrochloride (manufactured by Tokyo Chemical Industry Co., Ltd.) was added to 500 parts of absolute ethanol, refluxed for 8 hours, and cooled to room temperature. 20.2 parts of compounds represented by formula (a2-1) were slowly added dropwise to the obtained mixture over 5 hours. After the dropwise addition, the obtained mixture was stirred at 70° C. for 36 hours, and then cooled to room temperature to obtain 48.8 parts of a compound represented by the formula (a2).

[0490]

Synthetic example 2

[0492] 50 mL of methylene chloride was added to 28.52 parts of bis-N-ethyl-N-hydroxyethylaminobenzophenone and 17.80 parts of triethylamine, followed by stirring and dissolving. Then, 13.56 parts of methacrylic anhydride was added, and it heated up to 40 degreeC, and maintained. After the reaction was completed and cooled to room temperature, water was added to separate the layers, 20 mL of saturated saline was added, and the mixture was stirred for 30 minutes. After layer separation, the organic layer was distilled off, and the remaining solid was dried under reduced pressure to obtain 21.4 parts of the compound represented by the formula (aa2).

[0493]

[0494] 21.4 parts of the compound represented by formula (aa2) were added to 500 mL of chloroform, and stirred. Then, 49.08 parts of phosphorus oxychloride was added and stirred for 15 minutes. After adding 14.56 parts of N-phenyl-1-naphthylamine, it was made to reflux. After the reaction was completed, after cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content acid value | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com